Preparation method of ceramic substrate high-frequency copper-clad plate

A technology of ceramic substrate and copper clad laminate, applied in the field of preparation of high frequency copper clad laminate of ceramic substrate, can solve the problems of high dielectric loss, low mechanical properties and dimensional stability, poor electromagnetic shielding performance, etc., and achieve high impact resistance performance , Excellent electromagnetic shielding performance, good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

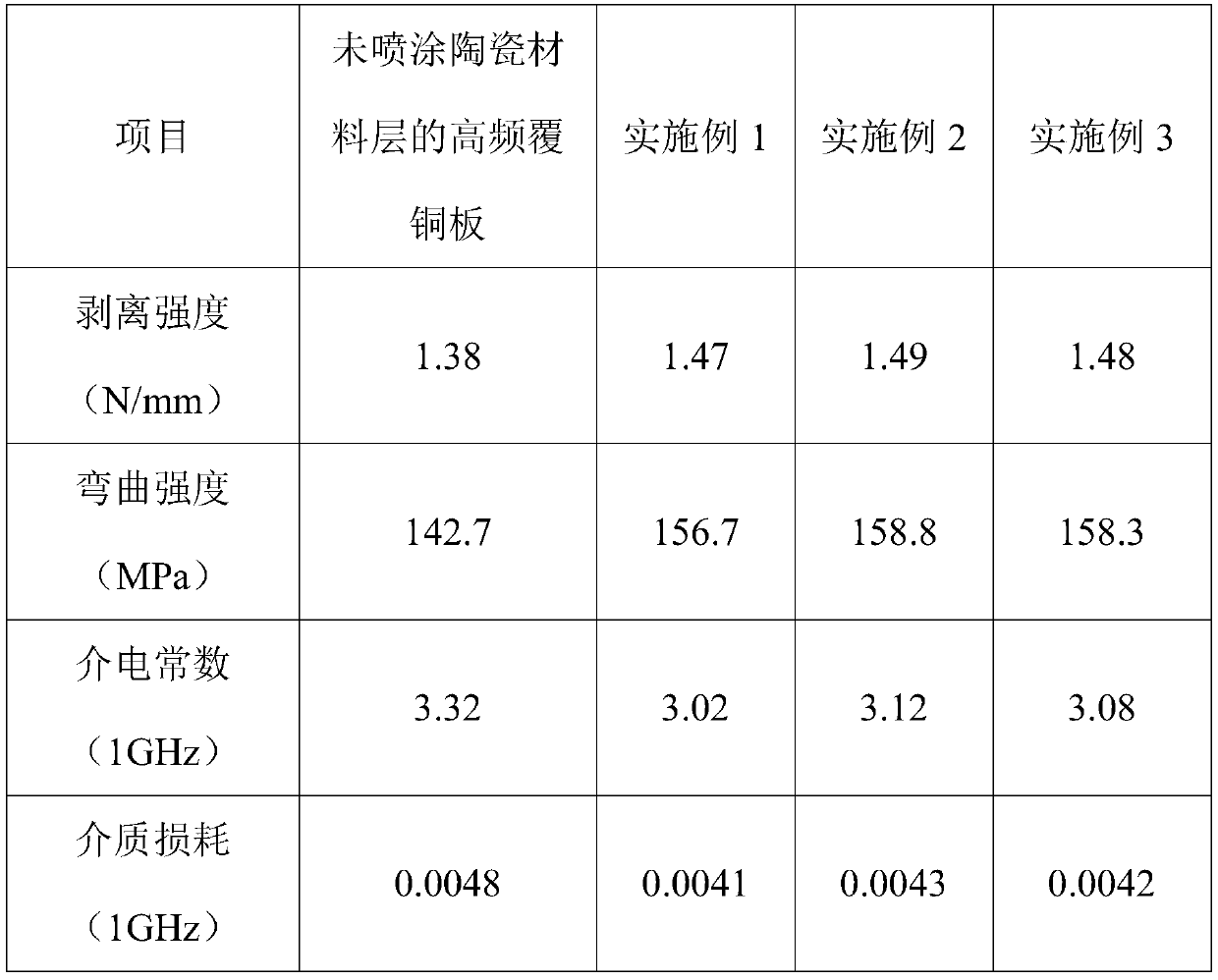

Examples

preparation example Construction

[0024] A method for preparing a high-frequency copper-clad laminate with a ceramic substrate, comprising the following steps:

[0025] 01. Substrate preparation;

[0026] 02. Plasma spraying ceramic material layer: uniform plasma spraying is carried out on the surface of the substrate, and the plasma spraying forms a ceramic material layer on the surface of the substrate, and the thickness of the ceramic material layer is 5-30 μm;

[0027] 03. Metal foil lamination and curing: apply a layer of glue on the surface of the ceramic material layer prepared above, and then cover it with metal foil, and then put it into a vacuum hot press for hot pressing and compounding to obtain a ceramic substrate with a high thickness. Frequency copper clad laminate. The glue solution is the glue solution prepared during the substrate preparation process.

[0028] Further, in the plasma spraying ceramic material layer in step 03, the spraying voltage is 40-60V, the current is 500-700A, the flow...

Embodiment 1

[0042] A method for preparing a high-frequency copper-clad laminate with a ceramic substrate, comprising the following steps:

[0043] 11. Add 120g of epoxy resin, 15g of diphenyl polyarylether, 30g of DDS curing agent and curing accelerator, add 45g of acetone solvent, after fully dissolving, add fillers (silicon dioxide and hydroxide with a particle size of 300-600nm Aluminum, the ratio is 3:2), and then mix and stir to obtain glue. Use NE-glass fiber cloth as a reinforcing material to impregnate the above glue solution, and then bake in an oven at 150-160°C for 8 minutes to cure to obtain the substrate;

[0044] 12. Adopt plasma spraying process to spray one layer of ceramic material layer on the substrate surface obtained above; h 2 ) flow rate of 6L / min, powder feeding gas (Ar) flow rate of 8g / min, and a distance of 15cm between the nozzle and the surface of the substrate to achieve uniform spraying on the surface of the substrate and form a ceramic material layer with ...

Embodiment 2

[0047] 21. Add 120g of epoxy resin, 15g of polyaryl ether, 30g of DDS curing agent and curing accelerator, and add 45g of acetone solvent. After fully dissolving, add fillers (silicon dioxide and hydroxide Aluminum, the ratio is 3:2), and then mix and stir to obtain glue. Use NE-glass fiber cloth as a reinforcing material to impregnate the above glue solution, and then bake in an oven at 150-160°C for 8 minutes to cure to obtain the substrate;

[0048] 22. Adopt plasma spraying process to spray a layer of ceramic material layer on the surface of the substrate obtained above; the ceramic material layer is TiN; the plasma spraying process is: spraying voltage 50V, current 600A, plasma gas (Ar) flow rate 40L / min, auxiliary gas ( h 2 ) flow rate of 6L / min, powder feeding gas (Ar) flow rate of 8g / min, and a distance of 15cm between the nozzle and the surface of the substrate to achieve uniform spraying on the surface of the substrate and form a ceramic material layer with a thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com