A three-dimensional nickel-doped iron-based oxygen evolution catalyst and its preparation method and application

A catalyst and three-dimensional technology, applied in the field of oxygen evolution catalysts, can solve the problems of low catalytic activity, high cost, complicated preparation, etc., and achieve the effects of excellent catalytic activity, improved catalytic activity and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

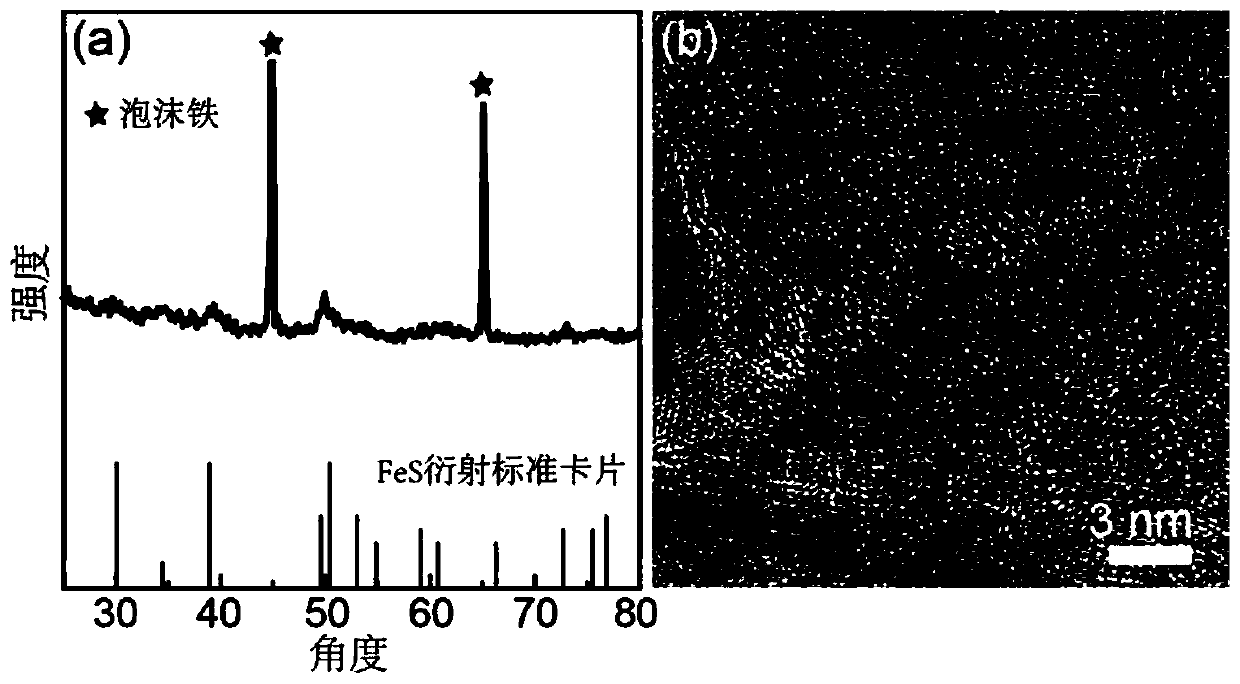

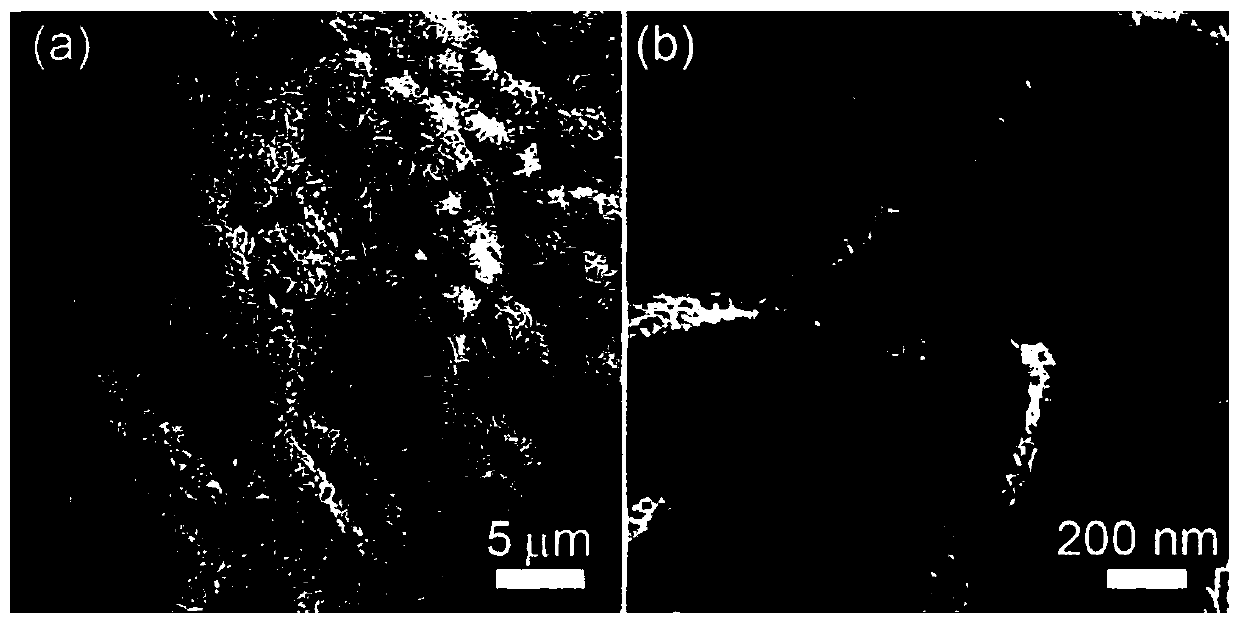

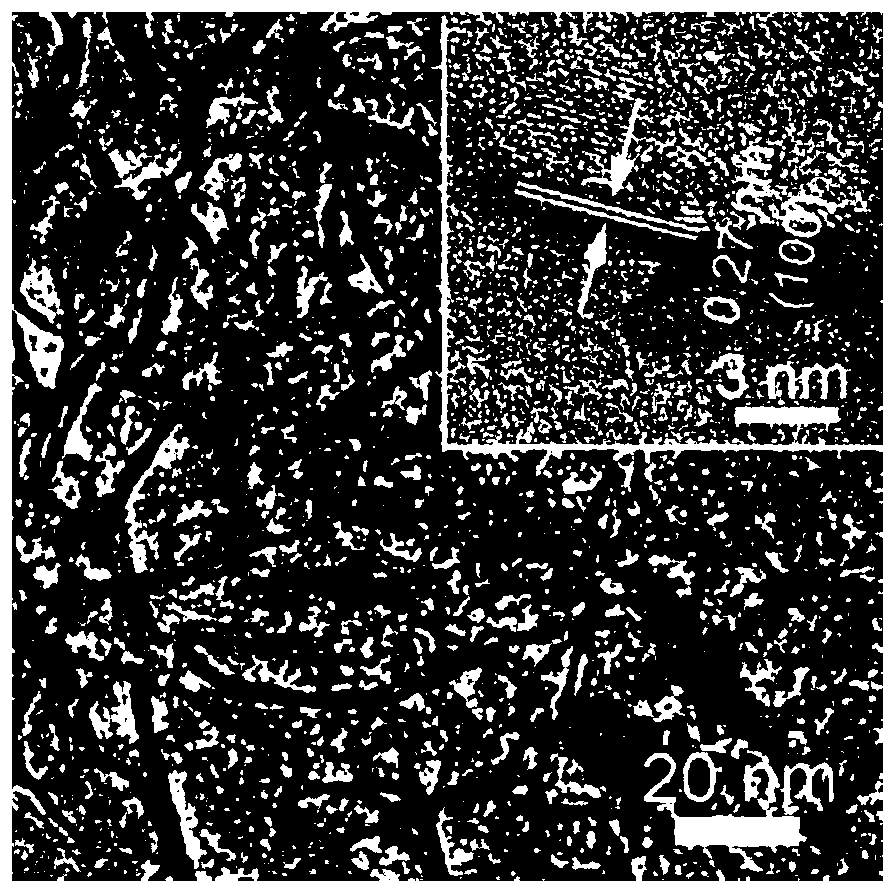

[0044] 6cm -2 The foam iron was pretreated by ultrasonic cleaning in ethanol, acetone and deionized water for 30 minutes; 15mL of 0.3mol / L sodium sulfide was added to a 25mL polytetrafluoroethylene reactor, and then pretreated The foam iron was subjected to a hydrothermal reaction at a temperature of 120°C for 12 hours. After the reaction, it was cooled to room temperature and rinsed several times with deionized deionized water until the washing liquid became clear, and then vacuum-dried at 60°C. After drying overnight, the conductive ultrathin ferrous sulfide nanosheets grown in situ on the foamed iron were obtained as a three-dimensional conductive framework. At room temperature, soak the three-dimensional conductive framework in 25mL of 15mmol / L nickel chloride solution for 5 minutes, take it out and rinse it with deionized water several times until the washing solution becomes clear, then at 60°C, vacuum Dry overnight to obtain a three-dimensional nickel-doped iron-based ...

Embodiment 2

[0052] Other preparation processes are all the same as in Example 1, except that the sodium sulfide in Example 1 is replaced with thiourea, and the ferrous sulfide nanosheets obtained in situ on the foamed iron become smaller, and oxygen, iron, sulfur and The atomic percentages of nickel are 67.41%, 19.04%, 4.12% and 9.43%, respectively.

Embodiment 3

[0054] Other preparation processes are all the same as in Example 1, and the difference is that the sodium sulfide in Example 1 is replaced with thioacetamide, and the ferrous sulfide nanosheets obtained in situ on foam iron become smaller, and oxygen, iron, The atomic percentages of sulfur and nickel are 65.32%, 21.37%, 4.81% and 8.50%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com