Bi-NPs@GO/Al composite hydrolysis hydrogen production material and preparation method thereof

A composite hydrolysis and compound technology, applied in the production of hydrogen and other directions, can solve the problems of inability to apply hydrogen, slow hydrolysis reaction rate, etc., and achieve the effects of producing anytime, anywhere, reducing hydrogen storage, and increasing the rate of hydrogen production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

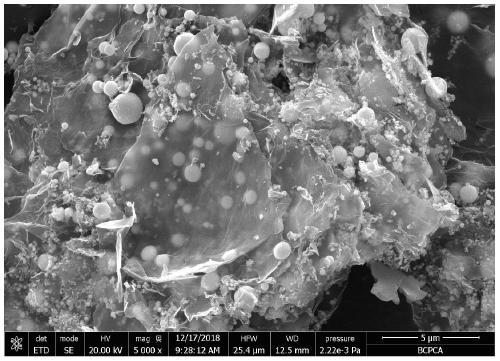

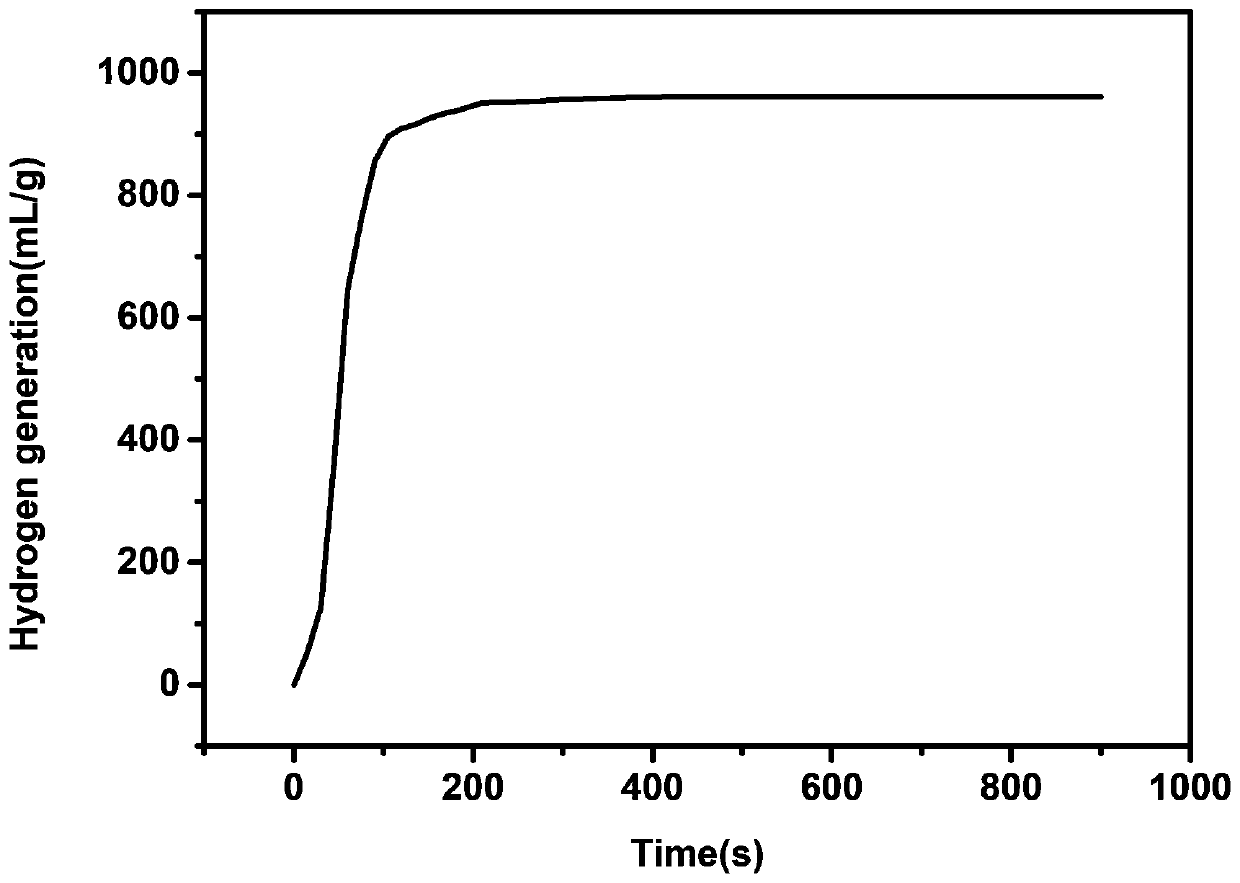

[0019] 100 mg of graphene oxide was ultrasonically dispersed in 100 mL of ethylene glycol, and 1 g of Bi(NO 3 ) 3 ·5H 2 O and 0.5g polyvinylpyrrolidone (PVP) were added to the ultrasonic dispersion of ethylene glycol and stirred for 30 minutes. Then the mixed solution was added into a hydrothermal reaction kettle, and reacted at 170° C. for 12 hours. After the reaction, the product was repeatedly washed with water and ethanol, and then dried at 70°C to obtain the Bi-NPs@GO composite.

[0020] 45g of aluminum powder and 5g of Bi-NPs@GO were added to the ball milling tank, and n-hexane was added as a protective solvent. Ball milling was carried out under the conditions of ball mass ratio of 20:1, ball mill speed of 800r / min, and ball milling time of 4h. After ball milling, cool for 30 minutes, and sieve and separate the ground metal powder to obtain the Bi-NPs@GO / Al composite hydrolysis hydrogen production material of the present invention, and then store the active material ...

Embodiment 2

[0023] 200mg graphene oxide was ultrasonically dispersed in 200mL ethylene glycol, 2.5g Bi(NO 3 ) 3 ·5H 2 O and 1g of polyvinylpyrrolidone (PVP) were added to the ultrasonic dispersion of ethylene glycol and stirred for 30 minutes. Then the mixed solution was added into a hydrothermal reaction kettle, and reacted at 170° C. for 12 hours. After the reaction, the product was repeatedly washed with water and ethanol, and then dried at 70°C to obtain the Bi-NPs@GO composite.

[0024] 47g of aluminum powder and 3g of Bi-NPs@GO were added to the ball milling tank, and n-hexane was added as a protective solvent. Ball milling was carried out under the conditions of ball mass ratio of 20:1, ball mill speed of 800r / min, and ball milling time of 4h. After ball milling, cool for 30 minutes, and sieve and separate the ground metal powder to obtain the Bi-NPs@GO / Al composite hydrolysis hydrogen production material of the present invention, and then store the active material powder.

[0...

Embodiment 3

[0027] 100mg graphene oxide was ultrasonically dispersed in 100mL ethylene glycol, 0.8g Bi(NO 3 ) 3 ·5H 2 O and 0.5g polyvinylpyrrolidone (PVP) were added to the ultrasonic dispersion of ethylene glycol and stirred for 30 minutes. Then the mixed solution was added into a hydrothermal reaction kettle, and reacted at 170° C. for 12 hours. After the reaction, the product was repeatedly washed with water and ethanol, and then dried at 70°C to obtain the Bi-NPs@GO composite.

[0028] 46g of aluminum powder and 4g of Bi-NPs@GO were added to the ball milling tank, and n-hexane was added as a protective solvent. Ball milling was carried out under the conditions of ball mass ratio of 20:1, ball mill speed of 800r / min, and ball milling time of 4h. After ball milling, cool for 30 minutes, and sieve and separate the ground metal powder to obtain the Bi-NPs@GO / Al composite hydrolysis hydrogen production material of the present invention, and then store the active material powder.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com