Method for preparing bacterium insulation polylactic acid superfine nanofiber wound dressing

A technology of ultra-fine nano and wound dressings, applied in the direction of fiber chemical characteristics, pharmaceutical formula, single-component polyester rayon, etc., can solve the problems of large pores, difficult to block bacteria, etc., achieve high specific surface area, enhanced release, The effect of promoting liquid absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

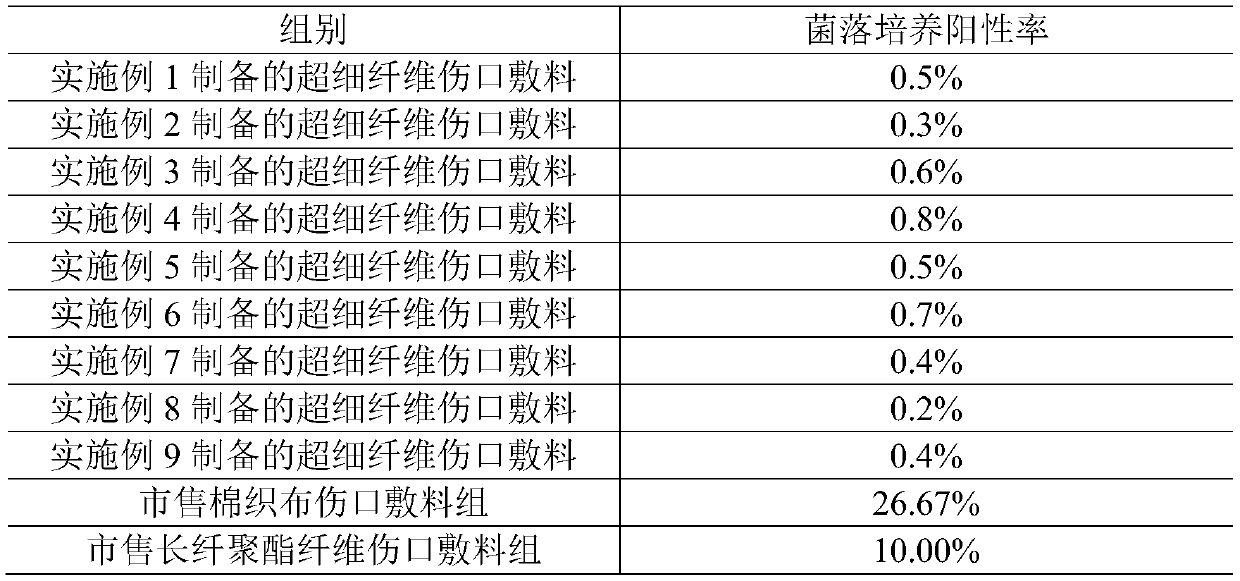

Embodiment 1

[0037] A kind of preparation method of bacteria-isolated polylactic acid ultrafine nanofiber wound dressing of the present invention, specifically carries out according to the following steps:

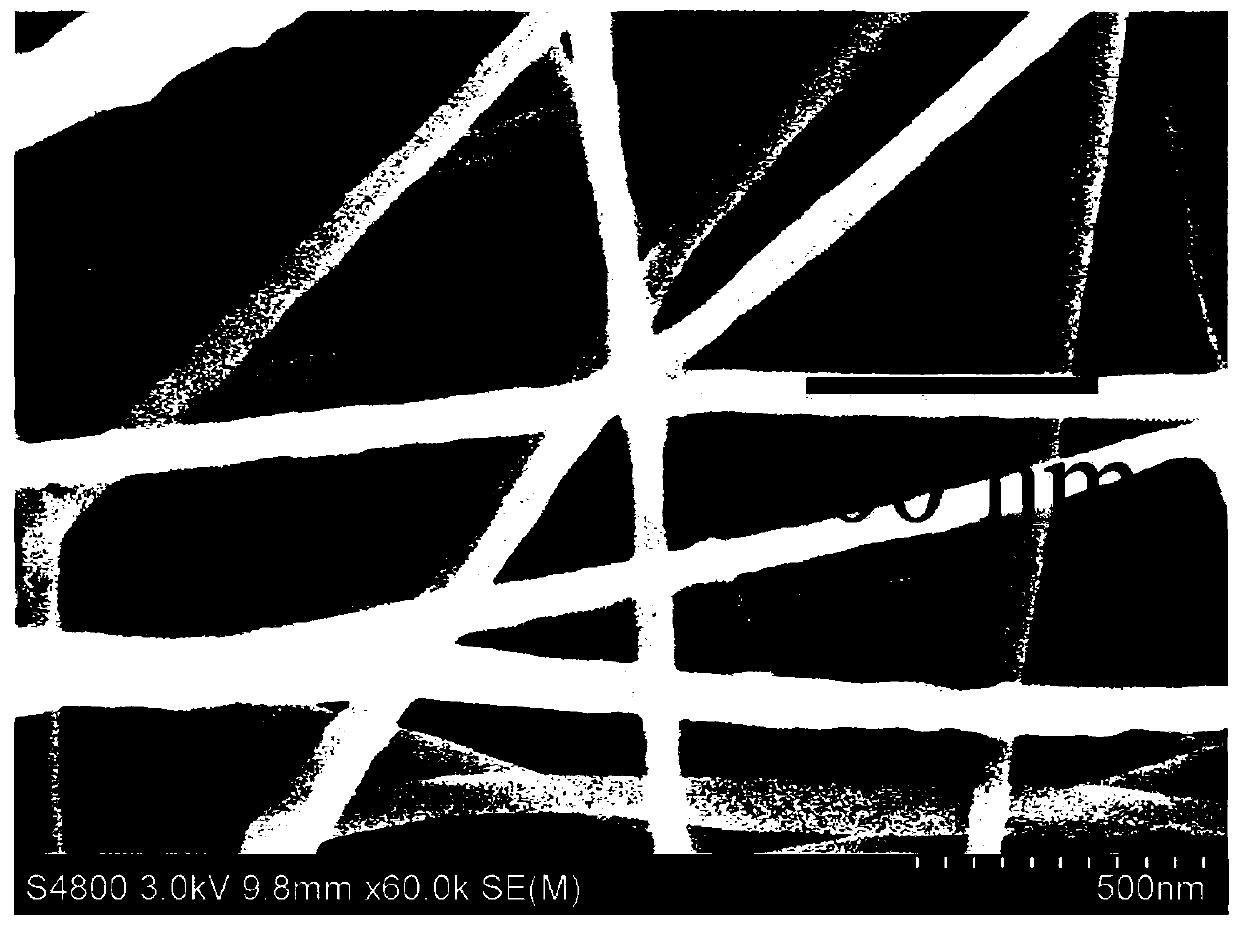

[0038] Step 1. Mix chloroform and dimethyl sulfoxide at a mass ratio of 1:0.11 and use it as a solvent to dissolve three-armed polylactic acid with a fiber diameter of 10 nm to 100 nm to obtain a three-armed polylactic acid solution with a mass concentration of 8%.

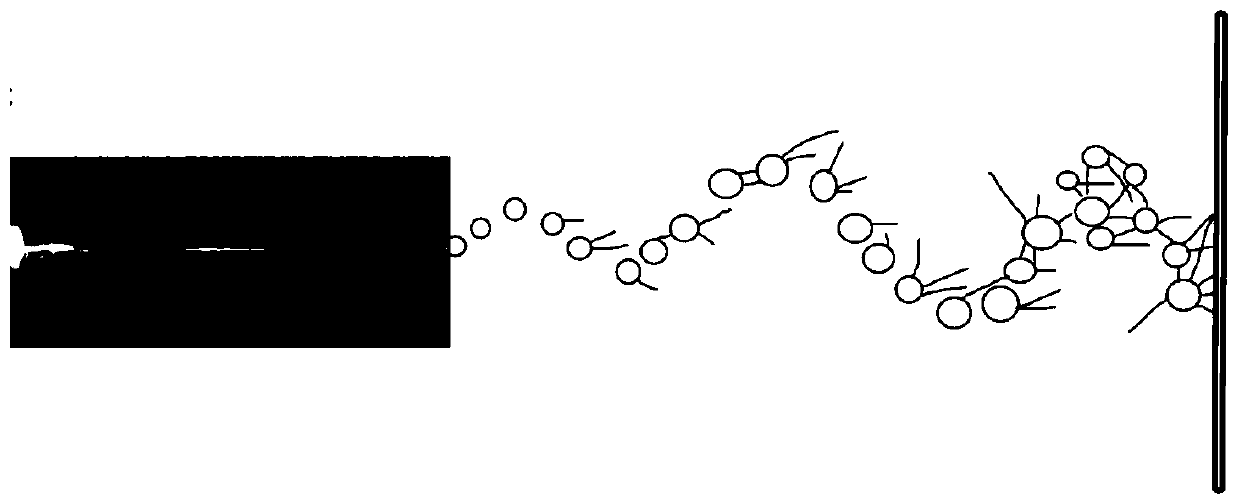

[0039] Step 2. Add the three-arm polylactic acid solution into the electrospinning device. Under the conditions of a voltage of 10KV, a liquid propeller speed of 0.15mm / s, and a receiving distance of 5cm, the particle size range of 10nm to 100nm is prepared by the jet method. The three-arm polylactic acid microfiber.

Embodiment 2

[0041] A kind of preparation method of bacteria-isolated polylactic acid ultrafine nanofiber wound dressing of the present invention, specifically carries out according to the following steps:

[0042] Step 1. Mix chloroform and dimethyl sulfoxide at a mass ratio of 1:0.25 and use it as a solvent to dissolve three-armed polylactic acid with a fiber diameter of 10 nm to 100 nm to obtain a three-armed polylactic acid solution with a mass concentration of 15%.

[0043] Step 2. Add the three-arm polylactic acid solution into the electrospinning device. Under the conditions of a voltage of 20KV, a liquid propeller speed of 0.18mm / s, and a receiving distance of 10cm, the jet method is used to prepare a particle size range of 10-100nm The three-arm polylactic acid microfiber.

Embodiment 3

[0045] A kind of preparation method of bacteria-isolated polylactic acid ultrafine nanofiber wound dressing of the present invention, specifically carries out according to the following steps:

[0046] Step 1. Mix chloroform and dimethyl sulfoxide at a mass ratio of 1:0.18 and use it as a solvent to dissolve three-armed polylactic acid with a fiber diameter of 10 nm to 100 nm to obtain a three-armed polylactic acid solution with a mass concentration of 15%.

[0047] Step 2. Add the three-arm polylactic acid solution into the electrospinning device, and use the jet method to prepare a particle size range of 10-100nm under the conditions of a voltage of 15KV, a liquid propeller speed of 0.2mm / s, and a receiving distance of 8cm. The three-arm polylactic acid microfiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com