Carbon aerogel natural gas adsorbing agent and preparation method and application thereof

A carbon aerogel and natural gas technology, which is applied in the preparation/purification of carbon, chemical instruments and methods, other chemical processes, etc., can solve problems such as inappropriate ANG technology, and achieve rich carbon content, which is conducive to industrialization, mechanical high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

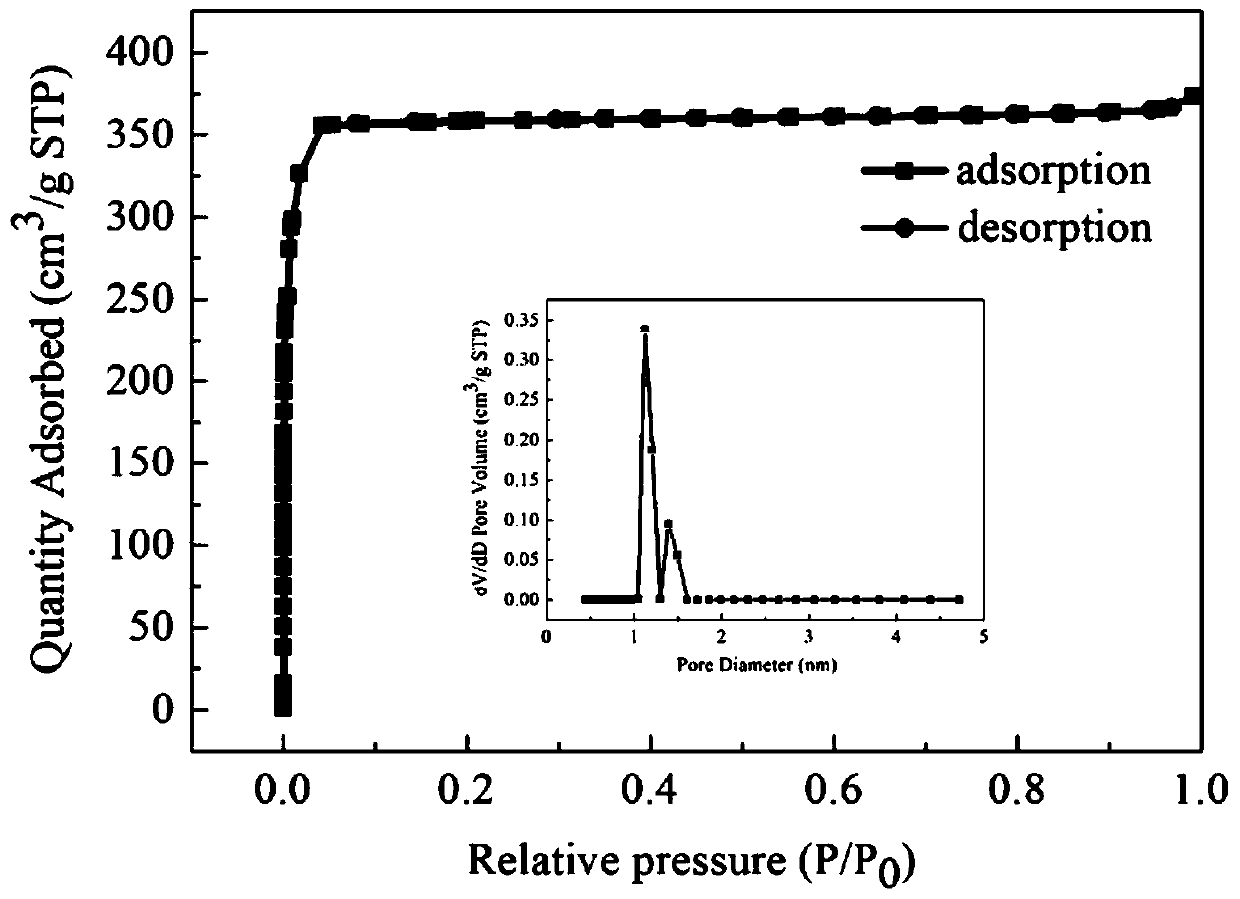

Image

Examples

Embodiment 1

[0039] A preparation method of carbon airgel natural gas adsorbent, comprising the steps of:

[0040] (1) 2wt% konjac glucomannan was dissolved in water, stirred for 0.5h, then put into liquid nitrogen for quick freezing, the freezing time was 35h, and then freeze-dried to obtain a carbon airgel precursor;

[0041] (2) the carbon airgel precursor that step (1) obtains in N 2 Carry out carbonization at 1000°C under the atmosphere, keep it warm for 1h, in N 2 Cool to room temperature under gas protection to obtain the carbon airgel material; then use the KOH activation method to chemically activate the carbon airgel material, wash to neutrality, and obtain the carbon airgel natural gas adsorbent.

Embodiment 2

[0043] A preparation method of carbon airgel natural gas adsorbent, comprising the steps of:

[0044] (1) 1wt% chitosan was dissolved in 2wt% acetic acid solution, stirred for 2 hours, then put into liquid nitrogen for quick freezing, the freezing time was 50 hours, and then freeze-dried to obtain a carbon airgel precursor;

[0045] (2) the carbon airgel precursor that step (1) obtains in N 2 Carry out carbonization at 800°C under the atmosphere, keep warm for 1.5h, in N 2 The carbon airgel material is obtained by cooling to room temperature under gas protection; then the carbon airgel material is chemically activated by the zinc chloride activation method, washed to neutrality, and the carbon airgel natural gas adsorbent is obtained.

Embodiment 3

[0047] A preparation method of carbon airgel natural gas adsorbent, comprising the steps of:

[0048] (1) Dissolve 1wt% bacterial cellulose in NaOH / urea solvent system, stir for 3h, then heat the obtained solution in a 60°C water bath for 4h to obtain a wet gel; dry it through a carbon dioxide supercritical drying system to obtain Xerogel;

[0049] (2) Carbonize the dry gel obtained in step (1) at 700°C under an Ar atmosphere, keep it warm for 3 hours, and cool it to room temperature under the protection of Ar gas to obtain a carbon airgel material; then use the phosphoric acid activation method to chemically synthesize the product activated by the method, and washed to neutrality to obtain the carbon airgel natural gas adsorbent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com