Titanate and titanium dioxide composite nanowire and preparation method thereof

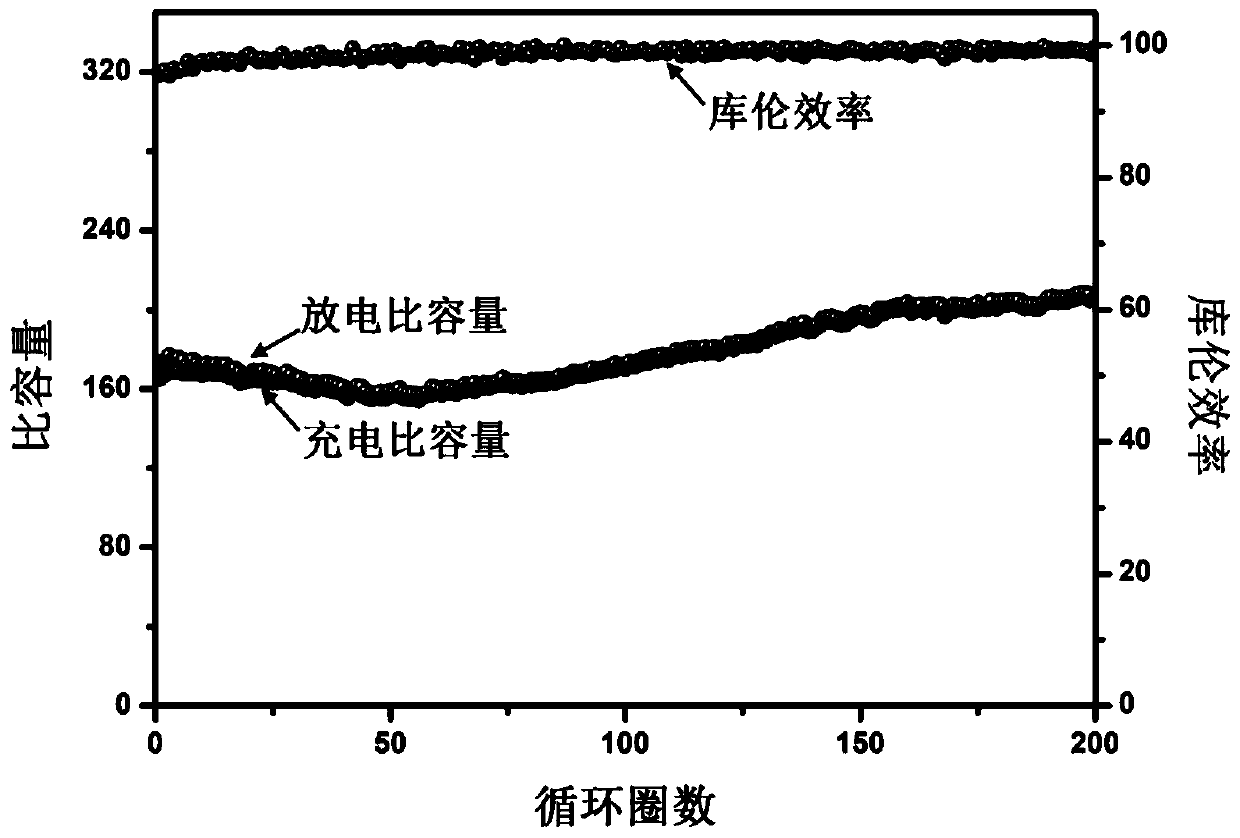

A technology of titanium dioxide and nanowires, which is applied in the field of material chemistry, can solve problems that restrict the development and application of carbon negative electrode materials, capacity fading, safety issues, etc., and achieve the effects of more active sites, growth inhibition, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

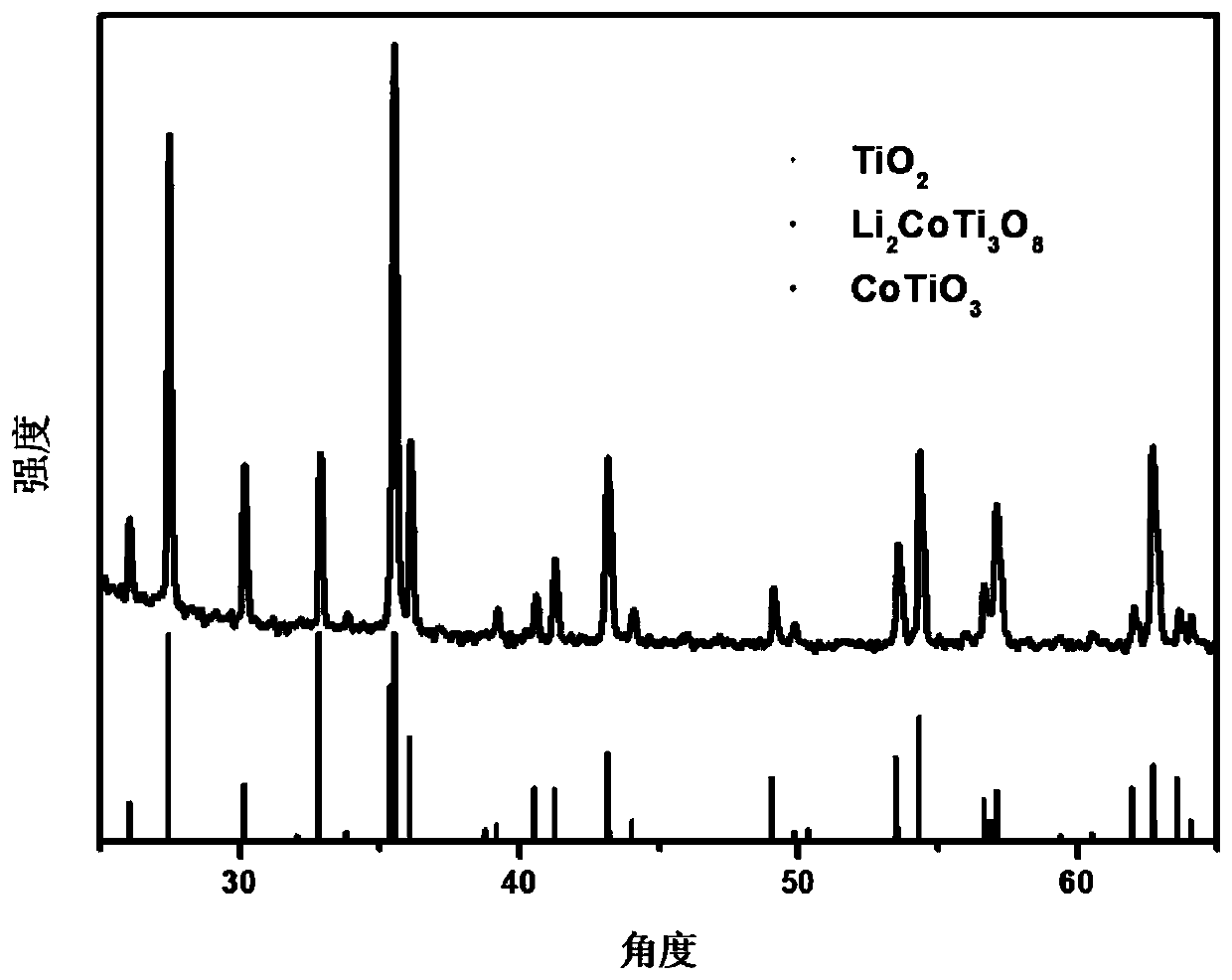

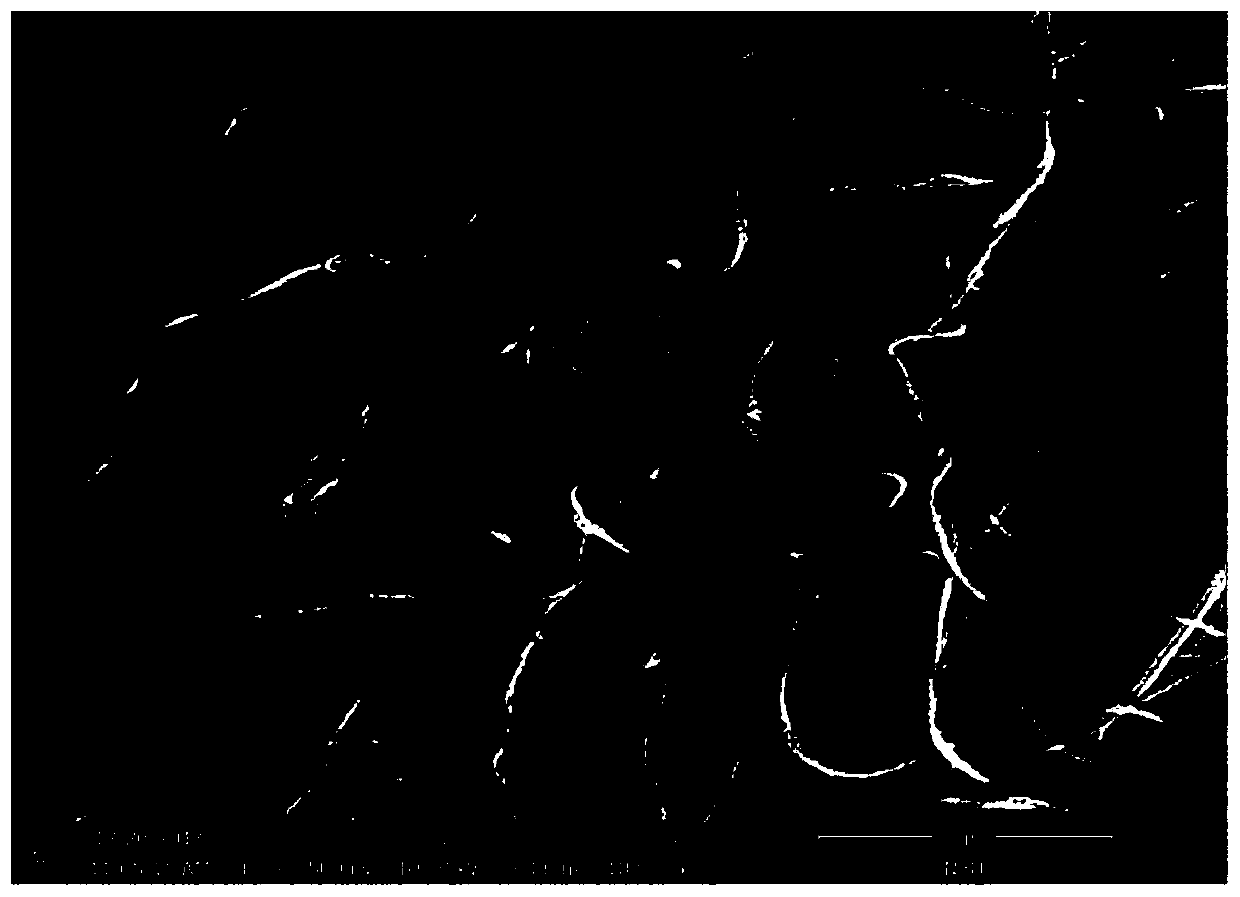

[0026] Add 5.0mL of N,N-dimethylformamide (DMF) to beaker A, then add 2.0mmoL (0.4982g) cobalt acetate tetrahydrate (C 4 h 6 CoO 4 4H 2 O), stirred for 0.5h, and cobalt acetate tetrahydrate was completely dissolved to obtain solution A, and the concentration of cobalt ions was 0.4mmol / mL; in beaker B, add 2.0mmoL (0.1320g) lithium acetate (C 2 h 3 LiO 2 ), and then add 2.0mL tetrabutyl titanate (C 16 h 36 o 4 Ti), 5.0mL absolute ethanol, 2.0mL acetic acid, stir for 0.5h to completely dissolve lithium acetate to obtain solution B, the concentration of lithium ions is about 0.22mmol / mL; slowly pour the solution in beaker B into beaker A , stirred for 0.5h, A and B solutions were mixed completely, added 1.40g of PVP (K-120, polyvinylpyrrolidone), stirred for 6h to form a clear spinning precursor solution C, and adjusted the pH of solution C to 2 with glacial acetic acid; Draw clear solution C into the syringe at a voltage of 15 kV, a receiving distance of 15 cm, and a flo...

Embodiment 2

[0028] Add 5.0mL of N,N-dimethylformamide (DMF) to beaker A, then add 2.00mmoL (0.4982g) cobalt acetate tetrahydrate (C 4 h 6 CoO 4 4H 2 O), stirred for 0.5h to completely dissolve cobalt acetate tetrahydrate to obtain solution A; add 2.0mmoL (0.1320g) lithium acetate (C 2 h 3 LiO 2 ), and then add 2.0mL tetrabutyl titanate (C 16 h 36 o 4 Ti), 5.0mL absolute ethanol, 2.0mL acetic acid, stir for 0.5h to completely dissolve lithium acetate to obtain solution B; slowly pour the solution in the B beaker into the A beaker, stir for 0.5h, and mix the A and B solutions Completely, add 1.40g of PVP (K-120, polyvinylpyrrolidone), stir for 6h to form a clear spinning precursor solution C, use glacial acetic acid to adjust the pH of solution C to 3.5; suck the clear solution C into the syringe, at 19kV The voltage, the receiving distance is 20cm, the flow rate is 0.6mL h -1 At a temperature of 35°C and a relative humidity of 30%, electrospinning was carried out; the obtained ele...

Embodiment 3

[0030] Add 5.0mL of N,N-dimethylformamide (DMF) to beaker A, then add 2.0mmoL (0.4982g) cobalt acetate tetrahydrate (C 4 h 6 CoO 4 4H 2 O), stirred for 0.5h to completely dissolve cobalt acetate tetrahydrate to obtain solution A; add 2.0mmoL (0.1320g) lithium acetate (C 2 h 3 LiO 2 ), and then add 2.0mL tetrabutyl titanate (C 16 h 36 o 4 Ti), 5.0mL absolute ethanol, 2.0mL acetic acid, stir for 0.5h to completely dissolve lithium acetate to obtain solution B; slowly pour the solution in the B beaker into the A beaker, stir for 0.5h, and mix the A and B solutions Completely, add 1.40g of PVP (K-120, polyvinylpyrrolidone), stir for 6h to form a clear spinning precursor solution C, use glacial acetic acid to adjust the pH of solution C to 2.5; suck the clear solution C into a syringe, The voltage, the receiving distance is 17.5cm, the flow rate is 0.4mL h -1 At a temperature of 30°C and a relative humidity of 25%, electrospinning was carried out; the obtained electrospinn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com