Alkali metal composite negative electrode and preparation method thereof and application of alkali metal composite negative electrode in preparing solid-state alkali metal battery

An alkali metal battery and alkali metal technology, applied in battery electrodes, secondary batteries, electrode carriers/current collectors, etc., can solve problems such as unsatisfactory lithium dendrite effect, uneven alkali metal recombination, and uneven lithium distribution. To achieve the effect of inhibiting the growth of dendrites, enhancing the ability to inhibit lithium dendrites, and improving the diffusion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

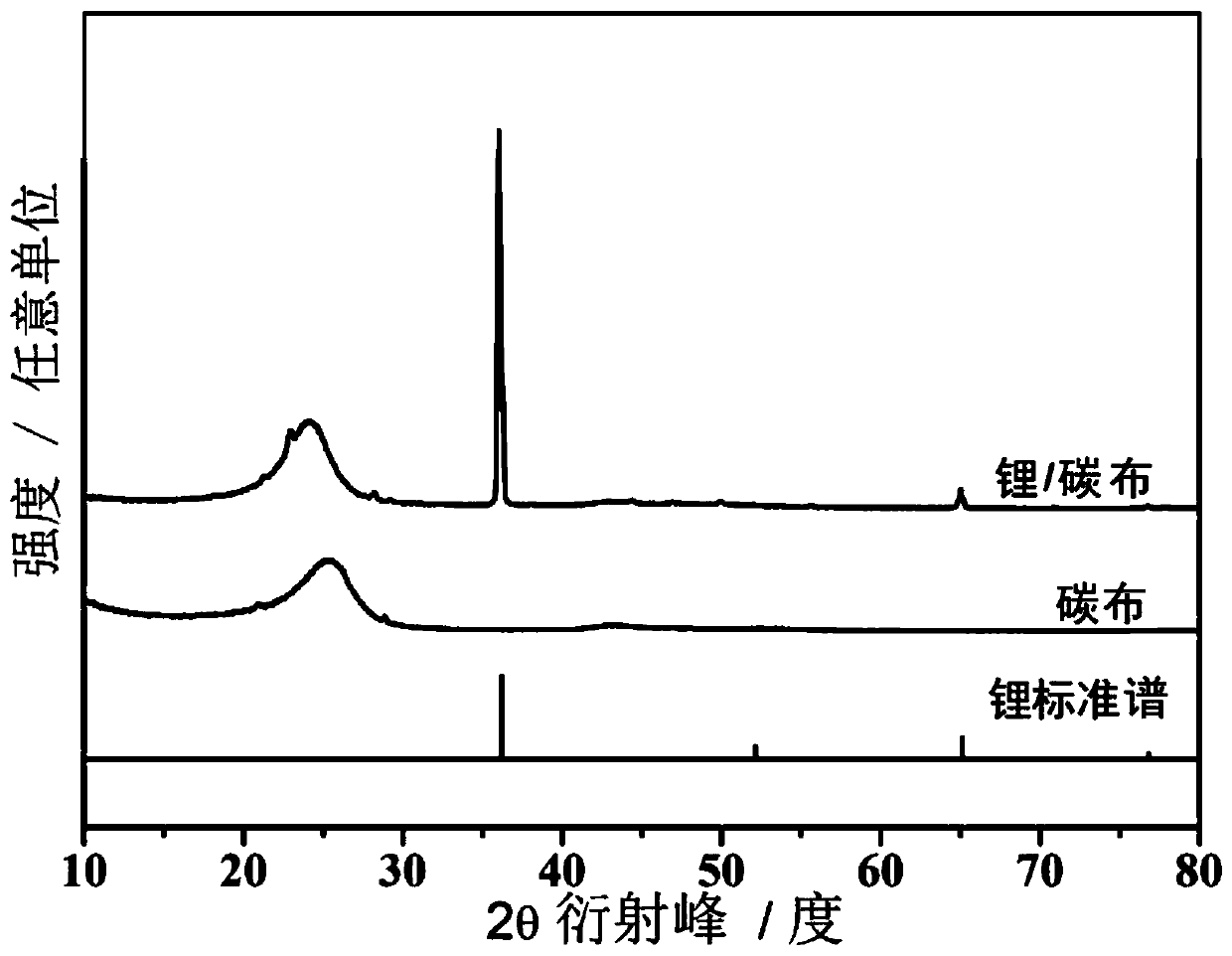

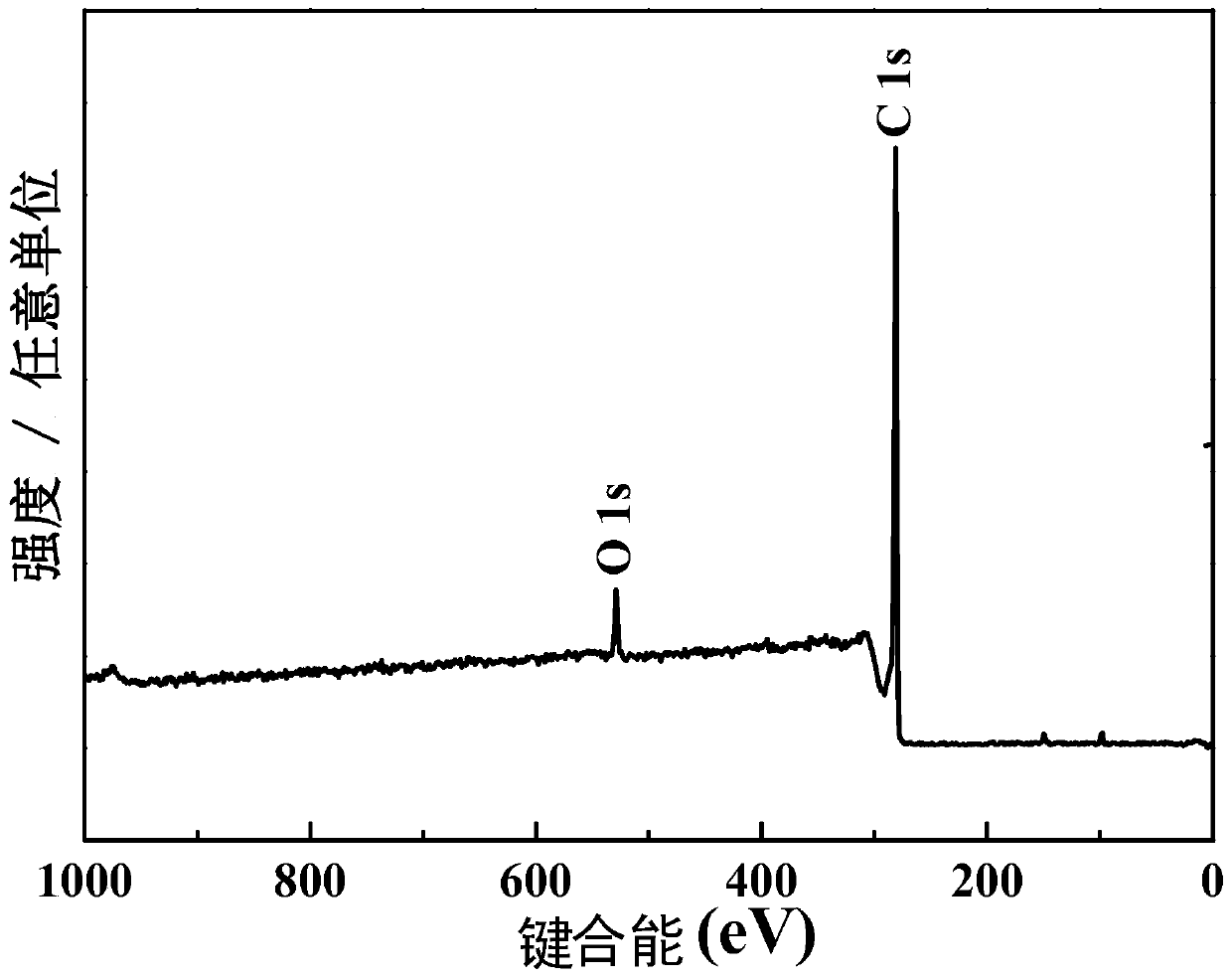

Embodiment 1

[0059] In an argon atmosphere, metal lithium is heated and melted, and then commercial carbon is placed on the surface of the molten lithium. After the carbon cloth is fully infiltrated by lithium, it is taken out, and naturally cooled to room temperature to obtain a lithium composite negative electrode; ethoxylated trimethylol Propane triacrylate monomer, Li 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 Ceramic powder (particle size 50-100nm), 1mol / L LiPF 6 The ethylene carbonate / propylene carbonate (volume ratio is 1:1) liquid electrolyte, mono-n-dodecyl phosphate is mixed in a weight ratio of 1:0.17:5:0.16, and fully stirred to obtain a solid electrolyte precursor Body; the above lithium composite bipolar, solid electrolyte precursor, commercial Celgard separator and LiCoO 2 The positive electrode is assembled into a liquid battery, and the initiator azobisisobutyronitrile (addition is 1wt% of the ethoxylated trimethylolpropane triacrylate monomer) is added, and then the battery is pack...

Embodiment 2

[0069] The preparation of the solid metal lithium battery is similar to Example 1, except that no functional additives are added to the solid electrolyte precursor. The obtained battery was tested at 60°C and 1C, and the capacity was 108mAh / g.

Embodiment 3

[0071] The preparation of the solid metal lithium battery is similar to Example 1, except that octyl phosphate is used as a functional additive instead of mono-n-dodecyl phosphate. The obtained battery was tested at 60°C and 1C, and the capacity was 120mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com