Ceramic blank crystalline glaze and preparation process thereof

A preparation process and technology of crystalline glaze, which is applied in the field of medium-temperature crystalline glaze and its production process, can solve the problems of small crystal flowers, high price, and high cost, and achieve the effect of smooth and bright glaze surface, high industrial value, and high yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

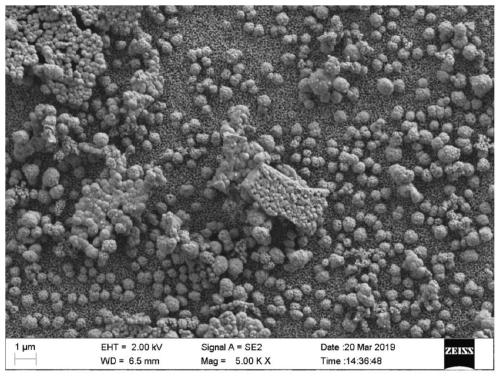

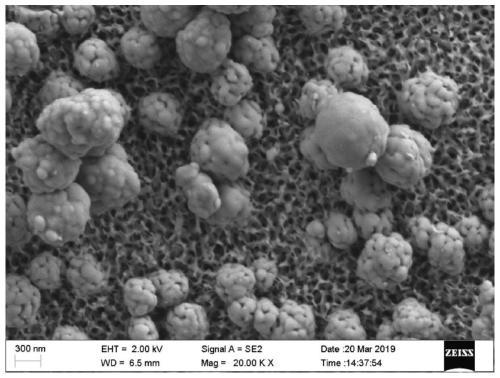

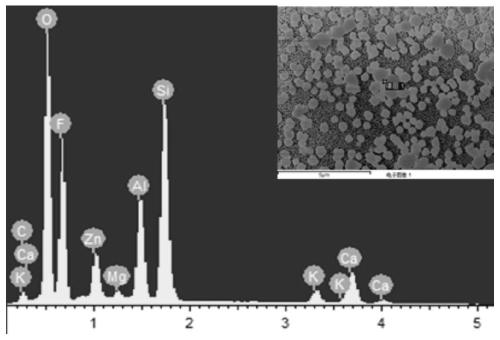

Image

Examples

Embodiment 1

[0048] A crystalline glaze for pottery blanks, comprising only 20 parts of glass powder, 20 parts of zinc oxide, 45 parts of feldspar, 10 parts of calcite, 4 parts of coloring agent A and 2 parts of coloring agent C in parts by weight. Glazing is applied to green bodies with an iron content of 8-12%.

[0049] 1) After weighing the raw materials according to the formula, pour the other raw materials into the ball mill tank except for zinc oxide. According to the material: ball: water = 1: 1.5: 1.1, quickly ball mill for 6 minutes, and the speed is 180-300r / min;

[0050] 2) Add the weighed zinc oxide to the ball-milled glaze in step 1), and continue ball milling for 2 minutes; after the end, pour out the glaze, pass it through an 80-mesh sieve, and set aside;

[0051] 3) The pottery is wiped clean with a sponge, and the surface of the pottery is dipped or sprayed once, and the thickness of the glaze layer is 1.0mm; only one glaze is required, no need to bury the crystal, the cry...

Embodiment 2

[0055] A crystalline glaze for pottery blanks, comprising only 30 parts of glass powder, 22 parts of zinc oxide, 35 parts of feldspar, 12 parts of calcite, 2 parts of coloring agent B and 2 parts of coloring agent D in parts by weight. Glaze is applied to terracotta blanks with an iron content of 10-12%.

[0056] 1) After weighing the raw materials according to the formula, pour the other raw materials into the ball mill tank except for zinc oxide. According to the material: ball: water = 1: 1.5: 1.1, quickly ball mill for 6 minutes, and the speed is 180-300r / min;

[0057] 2) Add the weighed zinc oxide to the ball-milled glaze in step 1), and continue ball milling for 2 minutes; after the end, pour out the glaze, pass it through an 80-mesh sieve, and set aside;

[0058] 3) The pottery is wiped clean with a sponge, and the surface of the pottery is dipped or sprayed once, with a thickness of 0.5mm; only one glaze is required, no need to bury the crystal, the crystal is natural,...

Embodiment 3

[0062] A crystalline glaze for pottery blanks, comprising only 20 parts of glass powder, 26 parts of zinc oxide, 45 parts of feldspar, 8 parts of calcite, 4 parts of coloring agent A and 2 parts of coloring agent B in parts by weight. Apply glaze to the purple sand body with an iron content of 8-15%, and fire it according to the following process:

[0063] 1) After weighing the raw materials according to the formula, pour the other raw materials into the ball mill tank except for zinc oxide. According to the material: ball: water = 1: 1.5: 1.1, quickly ball mill for 6 minutes, and the speed is 180-300r / min;

[0064] 2) Add the weighed zinc oxide to the ball-milled glaze in step 1), and continue ball milling for 2 minutes; after the end, pour out the glaze, pass it through an 80-mesh sieve, and set aside;

[0065] 3) The pottery is wiped clean with a sponge, and the surface of the pottery is glazed or sprayed once, and the thickness of the glaze layer is 1.5mm; only one glaze i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com