Sintered ceramsite having water retaining function, and preparation method thereof

A technology of ceramsite and function, which is applied in the field of sintered ceramsite with water retention function and its preparation, which can solve the problems of limited service life of flower ceramsite, poor effect of water and fertilizer retention, and poor fixation effect of ceramsite, so as to achieve good water retention Effect, beneficial to plant growth, and the effect of improving resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

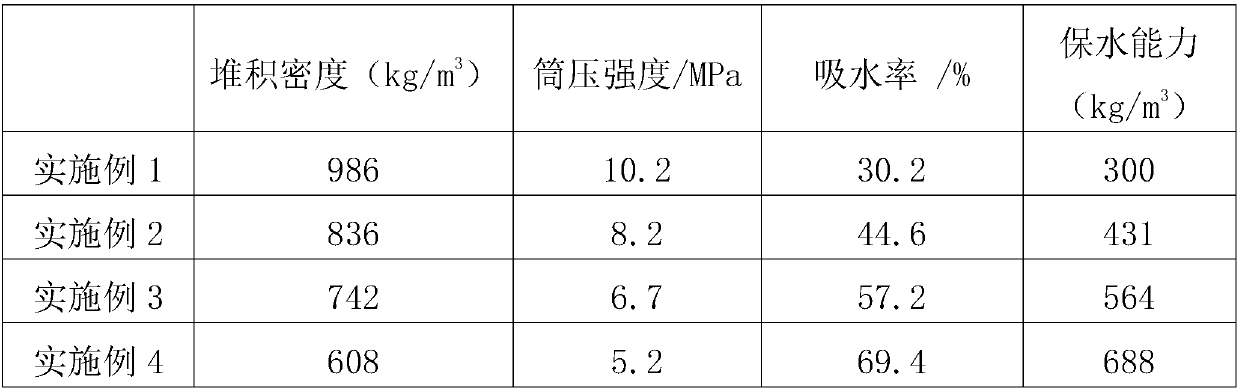

Embodiment 1

[0028] A sintered ceramsite with water retention function, the ceramsite is prepared from the following raw materials in parts by weight: 100 parts of solid waste, of which fly ash accounts for 10%, coal gangue accounts for 70%, slag accounts for 10%, ceramic polishing Waste materials account for 10%; plasticizer 5 parts, of which kaolin accounts for 10%, montmorillonite accounts for 25%, chlorite accounts for 38%, ethyl cellulose accounts for 27%; water reducer 0.5 parts, of which lignosulfonic acid Sodium accounts for 43.5%, polycarboxylate superplasticizer accounts for 56.5%; water 30 parts.

[0029] The preparation method of the sintered ceramsite with water retention function in the present embodiment comprises the following steps:

[0030] (1) Take the solid raw material according to the raw material proportion, and mix it uniformly in a forced mixer to obtain the mixture;

[0031] (2) Pour the mixture obtained in step (1) into a disc granulator, and pour water into it ...

Embodiment 2

[0035] A sintered ceramsite with water retention function, the ceramsite is prepared from the following raw materials in parts by weight: 100 parts of solid waste, of which fly ash accounts for 32%, coal gangue accounts for 41%, slag accounts for 13%, ceramic polishing Waste materials accounted for 14%; pore formers accounted for 12 parts, of which carbon powder accounted for 19%, expanded perlite accounted for 15%, palygorskite accounted for 34%, sepiolite accounted for 32%; plasticizers accounted for 8 parts, of which kaolin accounted for 28.4% , montmorillonite accounted for 27.5%, polyvinyl acetate accounted for 30.5%, paraffin accounted for 13.6%; 1 part of water reducer, of which sodium lignosulfonate accounted for 16.5%, polycarboxylate superplasticizer accounted for 40.8%, SM high efficiency Water reducing agent accounts for 42.7%; water 24 parts.

[0036] The preparation method of the sintered ceramsite with water retention function in the present embodiment comprises...

Embodiment 3

[0042] A sintered ceramsite with water retention function, the ceramsite is prepared from the following raw materials in parts by weight: 100 parts of solid waste, of which fly ash accounts for 32%, coal gangue accounts for 35%, slag accounts for 16%, ceramic polishing Waste materials accounted for 17%; 22 parts of pore-forming agents, of which graphite accounted for 26%, vermiculite accounted for 12%, palygorskite 31%, sepiolite accounted for 24%; plasticizers 11 parts, of which kaolin accounted for 32.5%, Mongolian Destonening accounted for 22.6%, chlorite accounted for 33.4%, polyethylene cellulose accounted for 11.5%; water reducing agent 1.6 parts, of which sodium lignosulfonate accounted for 11.2%, polycarboxylate superplasticizer accounted for 32.5%, SM high-efficiency Water reducing agent accounts for 56.3%; water 19 parts.

[0043] The preparation method of the sintered ceramsite with water retention function in the present embodiment comprises the following steps:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Cylinder compressive strength | aaaaa | aaaaa |

| Water retention capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com