Water-retaining liquid mulching film and preparation method and application thereof

A technology of liquid mulch and hydrophobic film, which is applied in the field of emulsion, can solve the problems that the film cannot play the role of water resistance and moisture retention, cannot play a good role in water retention, and increases production costs, so as to achieve excellent outdoor film-forming performance and prevent soil moisture from evaporating. , the effect of increasing water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The preparation of embodiment 1 liquid film

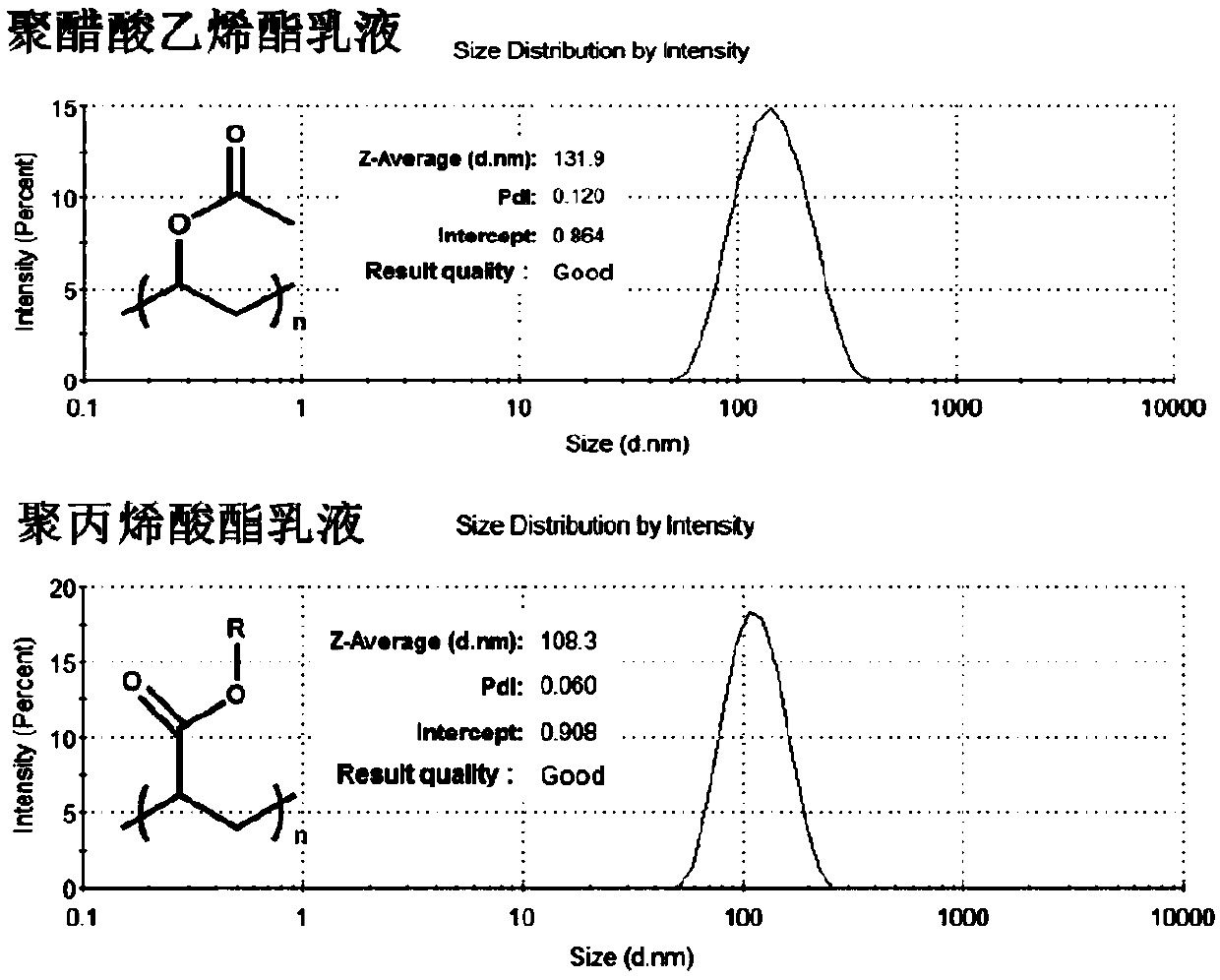

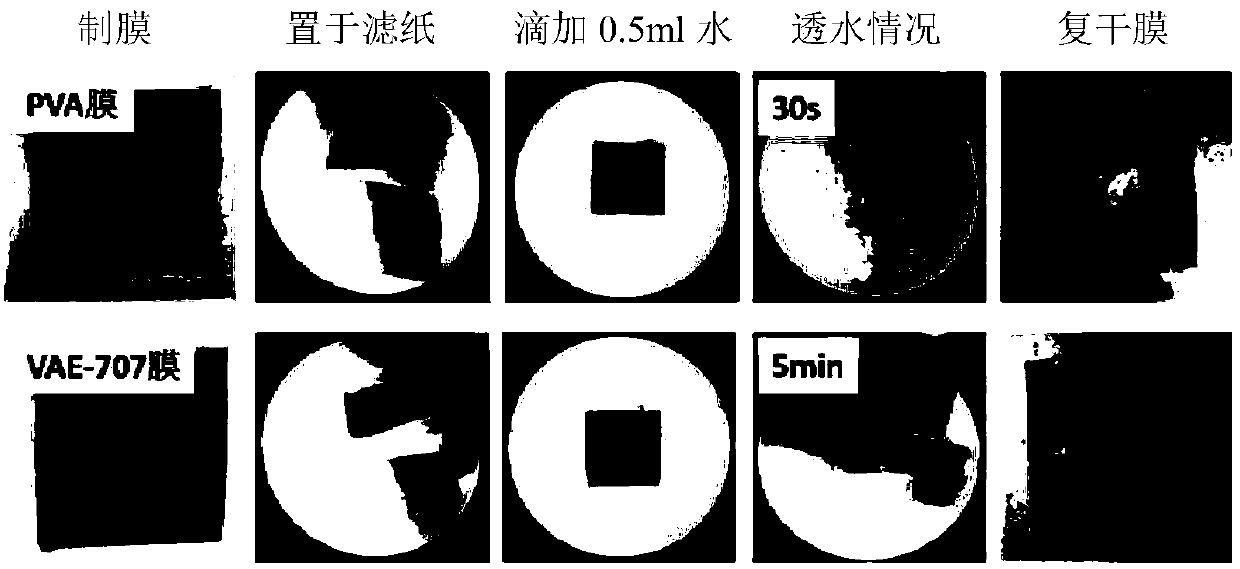

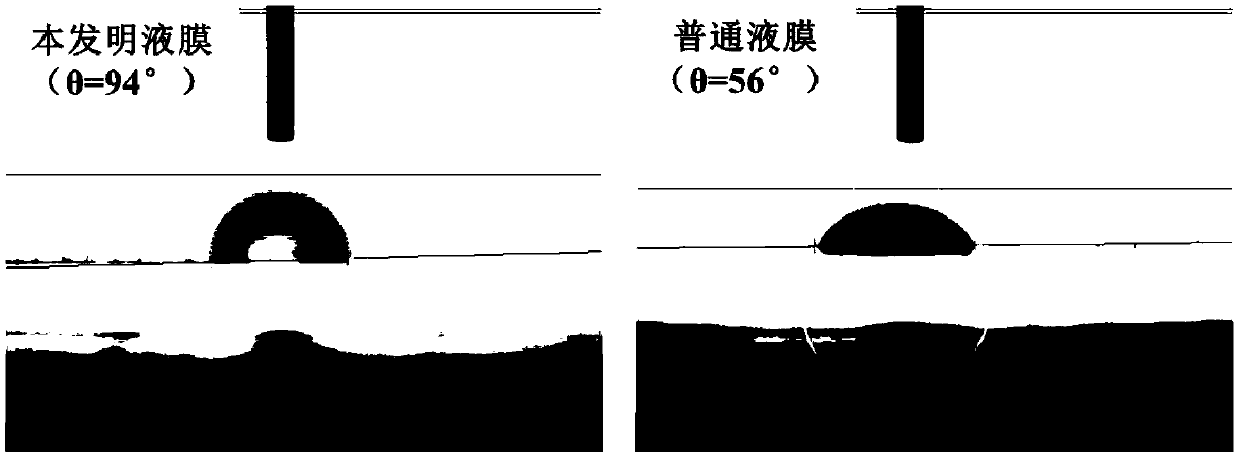

[0053] The liquid mulching film is prepared according to the components and dosages listed in Tables 1 to 5 below, the composition is calculated as 1000 parts by weight, and the balance is solvent water. Wherein, polymer nanoemulsion has particle diameter and is the latex particle of 50 nanometers~600 nanometers (referring to figure 1 ), the solid content is 50w / w%. The materials are sequentially fed into the stirring device to prepare liquid mulch. Focused on investigating the spraying performance and film-forming effect of liquid mulch, and conducted field experiments in yellow clay and sandy soil fields (crops are cabbage, cotton, etc.); also in Zhenjiang, Jiangsu, Wuhu / Huainan port coal yards , The mine has done a dust suppression test in the coal area.

[0054] Table 1 Formula composition of liquid mulch F1

[0055] materials Dosage (parts by weight) polyacrylate emulsion 40 polyvinyl alcohol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com