Corrosion-resistant metal ceramic and preparation method thereof

A cermet, corrosion-resistant technology, applied in the field of ceramic materials, can solve the problems of cermet low-temperature strength, unsatisfactory strong alkali corrosion resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

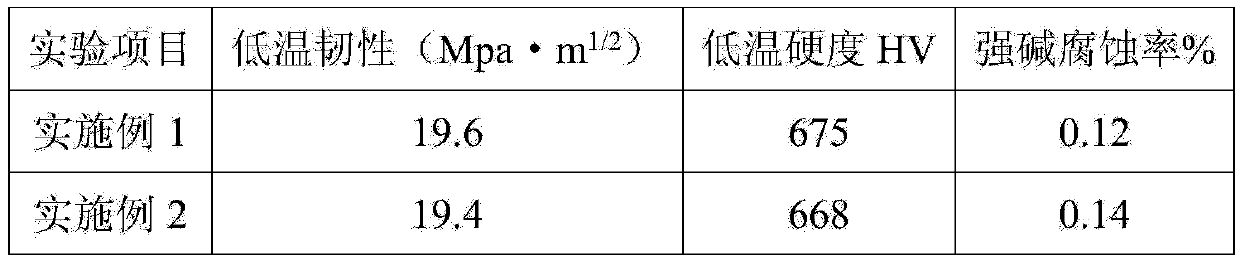

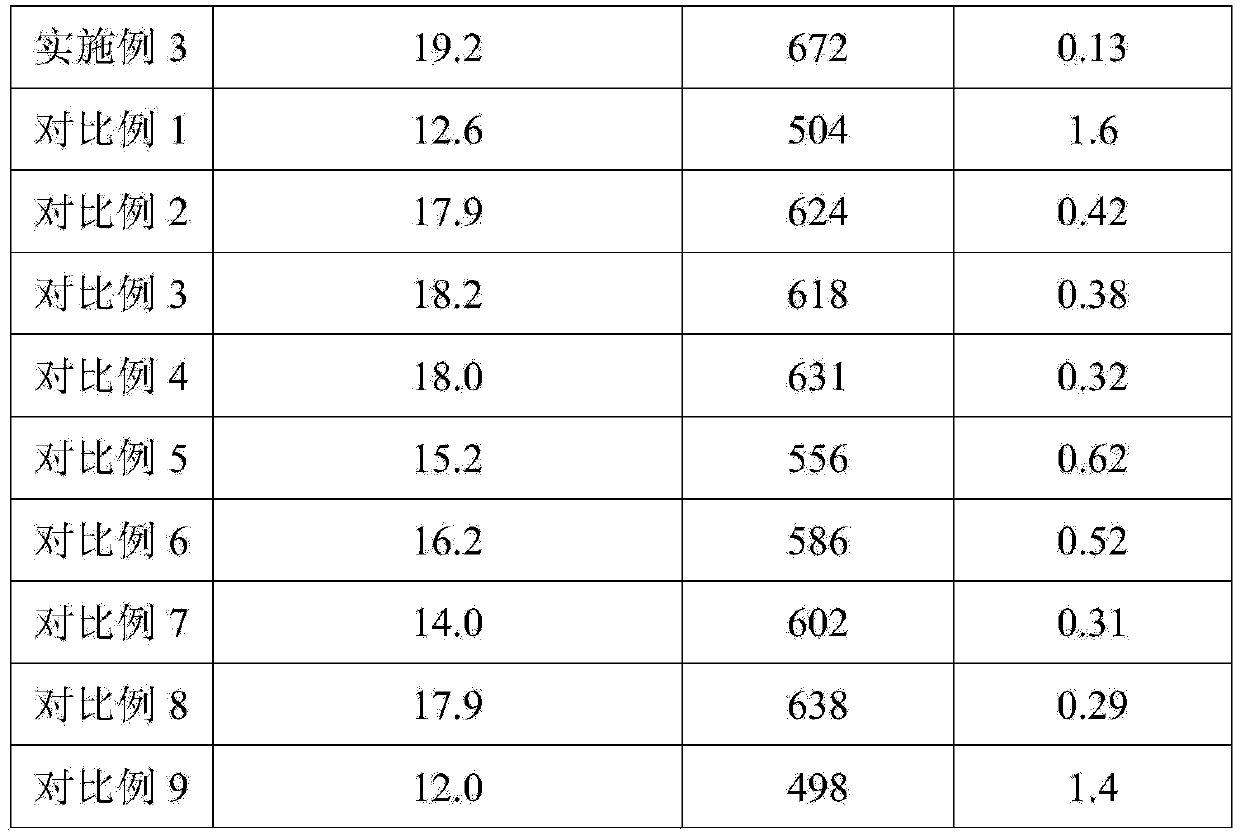

Examples

Embodiment 1

[0019] A corrosion-resistant cermet comprising the following components by weight: 23 parts of copper oxide, 17.5 parts of silicon dioxide, 15 parts of graphite, 12.5 parts of zinc nitride, 7.5 parts of nickel, and 7.5 parts of molybdenum oxide , 7.5 parts of polytetrafluoroethylene, 4 parts of sodium tripolyphosphate, 0.5 parts of tributyltin methacrylate, 3 parts of terminal hydrogen silicone oil, 7.5 parts of red mud, and 6 parts of polyaluminum chloride.

[0020] The basicity of the polyaluminum chloride is 30%.

[0021] According to the preparation method of above-mentioned corrosion-resistant cermet, comprise the following steps: (1) at first copper oxide, silicon dioxide, graphite, zinc nitride, nickel, molybdenum oxide are put into ball mill respectively in ball mill; (2) copper oxide , zinc nitride and molybdenum oxide are evenly mixed and put into a calciner for ablation; (3) put the obtained product in the previous step into a pulverizer for pulverization, pass thro...

Embodiment 2

[0023] A corrosion-resistant cermet comprising the following components by weight: 18 parts of copper oxide, 20 parts of silicon dioxide, 10 parts of graphite, 15 parts of zinc nitride, 5 parts of nickel, and 10 parts of molybdenum oxide , 5 parts of polytetrafluoroethylene, 5 parts of sodium tripolyphosphate, 0.1 part of tributyltin methacrylate, 4 parts of hydrogen silicone oil, 5 parts of red mud, and 8 parts of polyaluminum chloride. The basicity of the polyaluminum chloride is 30%.

[0024]According to the preparation method of above-mentioned corrosion-resistant cermet, comprise the following steps: (1) at first copper oxide, silicon dioxide, graphite, zinc nitride, nickel, molybdenum oxide are put into ball mill respectively in ball mill; (2) copper oxide , zinc nitride and molybdenum oxide are evenly mixed and put into a calciner for ablation; (3) put the obtained product in the previous step into a pulverizer for pulverization, pass through a 100-mesh sieve, put it in...

Embodiment 3

[0026] A corrosion-resistant cermet comprising the following components by weight: 25 parts of copper oxide, 15 parts of silicon dioxide, 20 parts of graphite, 10 parts of zinc nitride, 10 parts of nickel, and 5 parts of molybdenum oxide , 10 parts of polytetrafluoroethylene, 3 parts of sodium tripolyphosphate, 1 part of tributyltin methacrylate, 2 parts of hydrogen-terminated silicone oil, 10 parts of red mud, and 4 parts of polyaluminum chloride. The basicity of the polyaluminum chloride is 30%.

[0027] According to the preparation method of above-mentioned corrosion-resistant cermet, comprise the following steps: (1) at first copper oxide, silicon dioxide, graphite, zinc nitride, nickel, molybdenum oxide are put into ball mill respectively in ball mill; (2) copper oxide , zinc nitride and molybdenum oxide are evenly mixed and put into a calciner for ablation; (3) put the obtained product in the previous step into a pulverizer for pulverization, pass through a 100-mesh siev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com