Macromolecular micro-particle and preparation and application thereof

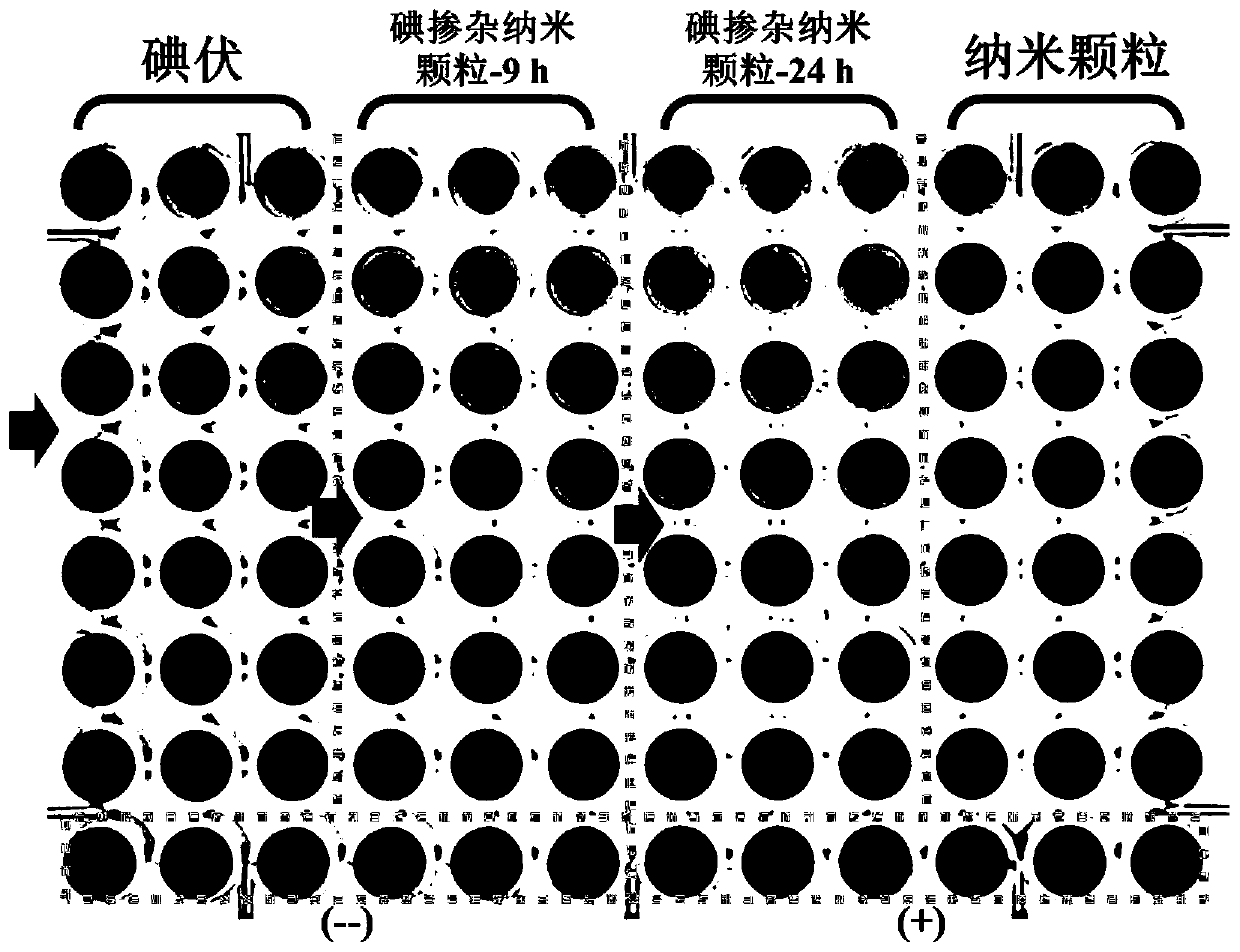

A technology of macromolecules and microparticles, applied in the field of macromolecular microparticles doped with unsaturated double bonds of iodine, can solve the problems of cell damage and high cost, and achieve the effects of promoting growth, low production cost and low cytotoxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

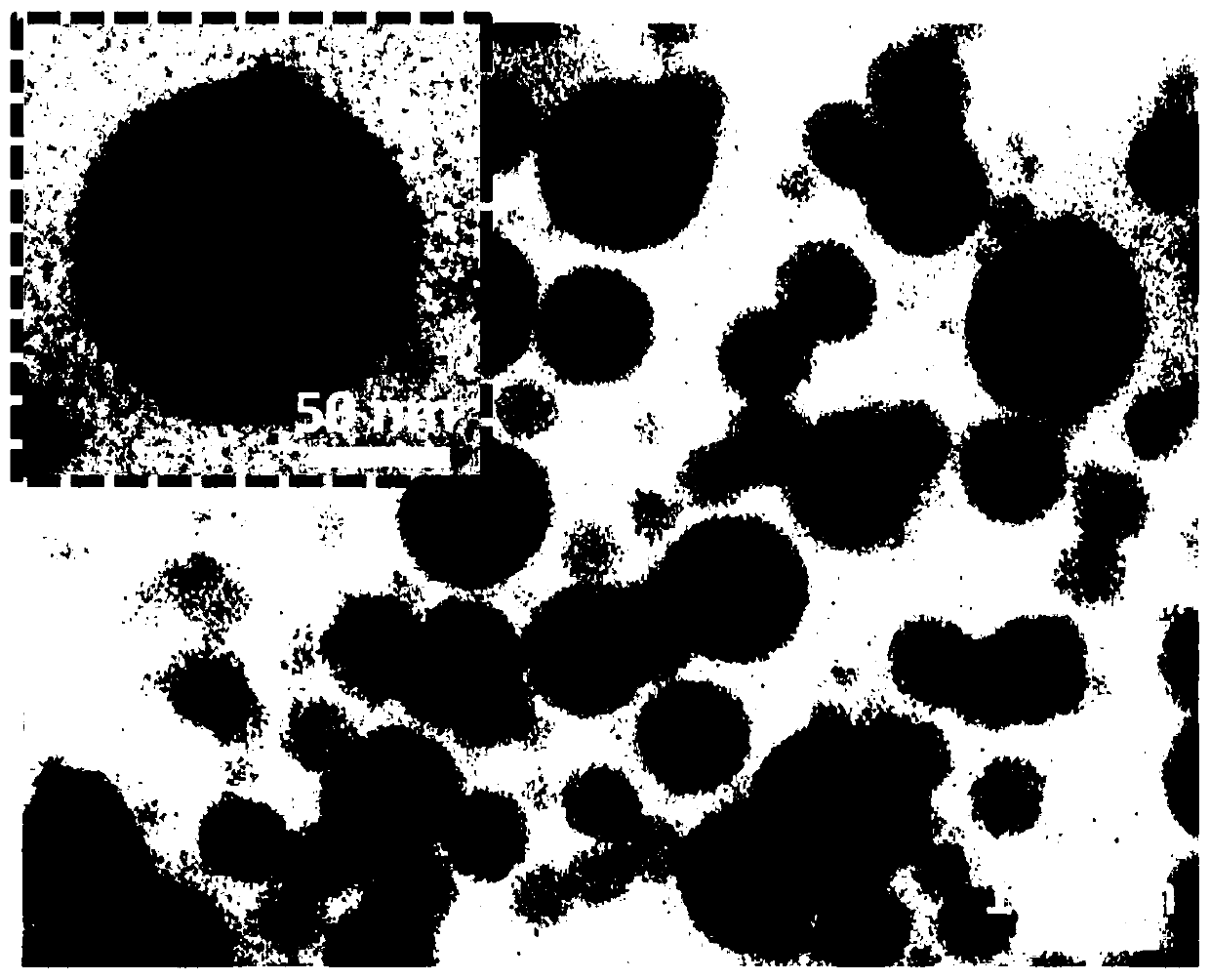

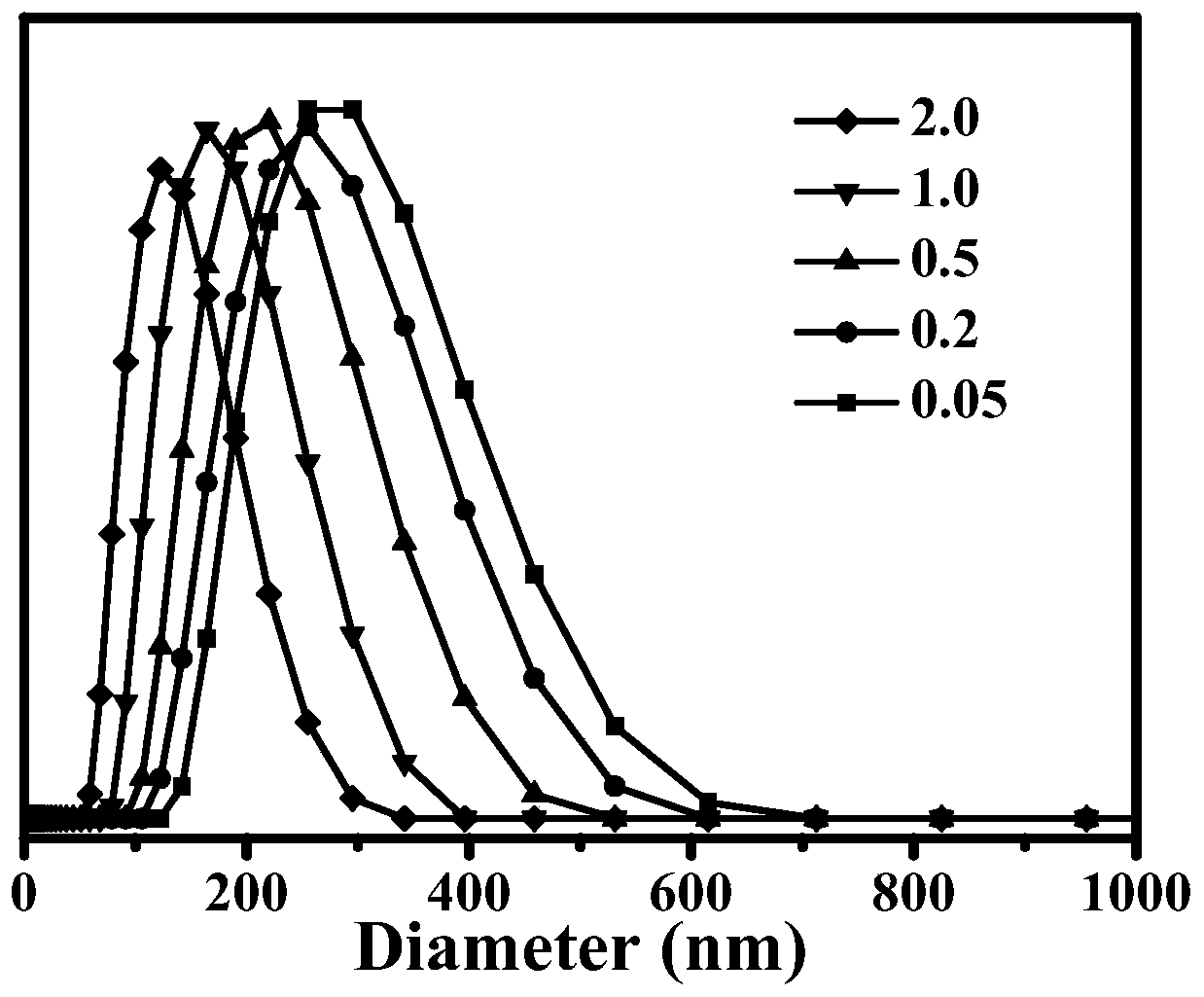

[0056] Embodiment 1, preparation contains the macromolecule particle of double bond

[0057] The microparticles are prepared from the following raw materials: trans polyisoprene, toluene, water, polyvinyl alcohol;

[0058] The preparation method comprises the following steps: dissolving trans-polyisoprene in toluene at 2% mass volume percentage, stirring at room temperature overnight at 1500 r / min, to obtain an oil phase;

[0059] Take polyvinyl alcohol and dissolve it in water at 0.5% mass volume percentage, that is, dissolve 0.5g polyvinyl alcohol in 100mL deionized water, and stir at room temperature overnight at 1500r / min to obtain an aqueous phase;

[0060] Add 9 parts of the water phase and 1 part of the oil phase, close the container, ultrasonically disperse for 2 hours, then open the container, and remove the organic solvent in the system by ultrasonic volatilization for 4 hours at 55°C to obtain a water dispersion of polymer microparticles (high The concentration of ...

Embodiment 2

[0065] Example 2, preparation of polymer microparticles containing double bonds

[0066] The microparticles are prepared from the following raw materials: cis-polyisoprene, toluene, water, and polyvinyl alcohol;

[0067] The preparation method comprises the following steps: dissolving cis-polyisoprene in toluene at a mass volume percentage of 2%, stirring at room temperature overnight at 1500 r / min, to obtain an oil phase;

[0068] Take polyvinyl alcohol and dissolve it in deionized water at 2% mass volume percentage, stir overnight at room temperature at 1500r / min to obtain the water phase; add 9 parts of the water phase and 1 part of the oil phase, seal the container, and ultrasonically disperse for 2 hours , then open the container, and under the condition of 55°C, ultrasonically volatilize for 4 hours to remove the organic solvent, and obtain the aqueous dispersion of polymer microparticles;

[0069] The difference from the above-mentioned Example 1 is that the double bon...

Embodiment 3

[0070] Example 3, preparation of polymer microparticles containing double bonds

[0071] The microparticles are prepared from the following raw materials: trans polyisoprene, toluene, water, polyvinyl alcohol;

[0072] The preparation method comprises the following steps: dissolving trans-polyisoprene in toluene at 2% mass volume percentage, stirring at room temperature overnight at 1500 r / min, to obtain an oil phase;

[0073] Sodium lauryl sulfate was dissolved in deionized water at 0.5% mass volume percentage, and stirred at room temperature overnight at 1500 r / min to obtain an aqueous phase;

[0074] Add 9 parts of the water phase and 1 part of the oil phase, close the container, ultrasonically disperse for 2 hours, then open the container, and remove the organic solvent by ultrasonic volatilization for 4 hours under the condition of 65°C to obtain a water dispersion of polymer particles;

[0075] The difference from the above-mentioned Example 1 is that the surfactant is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com