Modified corn straw cellulose adsorbent, and preparation method and application thereof

A technology of corn stalks and cellulose, which is applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., to achieve high adsorption capacity, efficient utilization of resources, and simple and easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1: Preparation of Modified Corn Stalk Cellulose Adsorbent

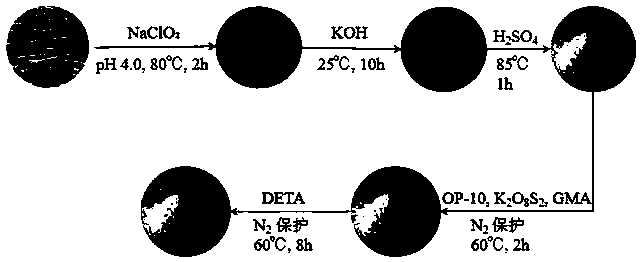

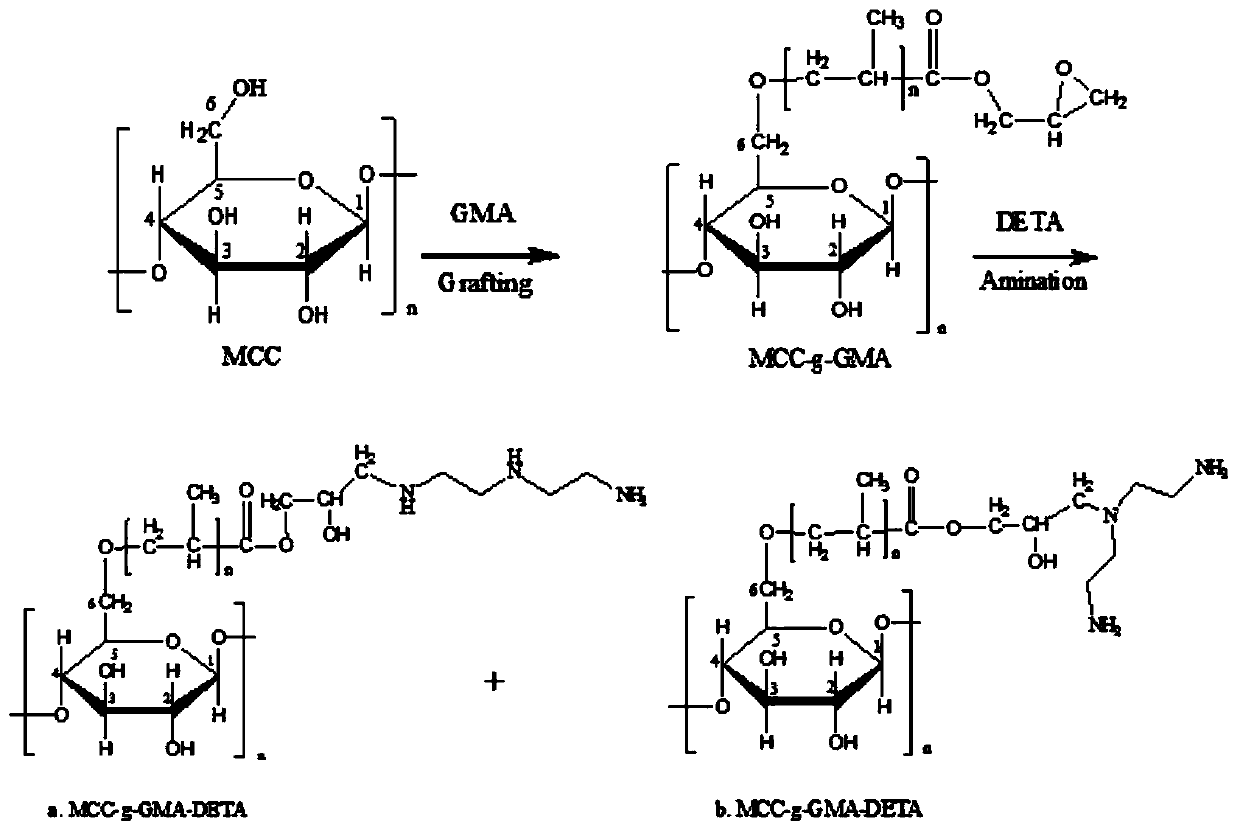

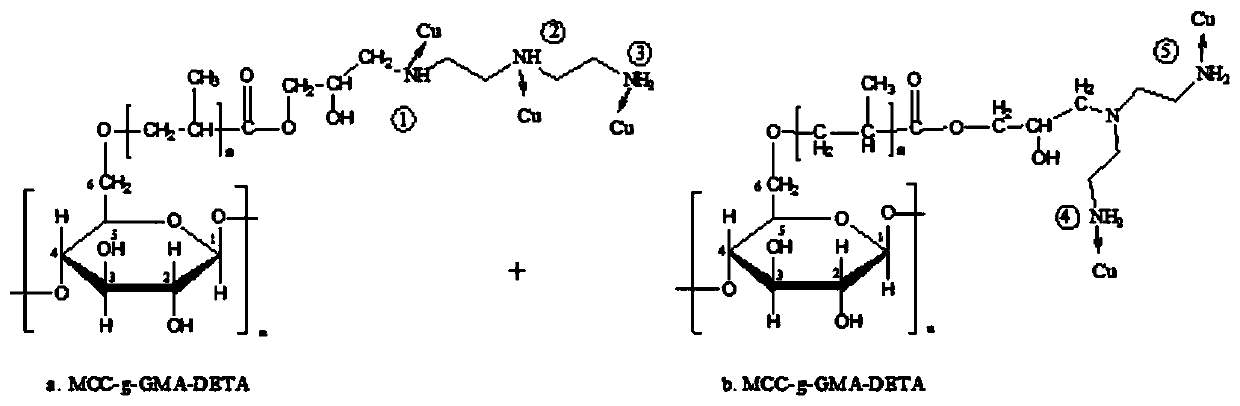

[0049] Such as figure 1 and figure 2 As shown, through the grafting reaction, other groups are introduced on the cellulose matrix, the hydrogen bonds between the cellulose molecules are broken, and then the epoxy group is used to react with DETA to prepare aminated modified cellulose.

[0050] The first step is to obtain corn stalk cellulose: ① After removing the stalk heads, leaves and excess roots, the collected corn stalks are cut into several sections, washed with deionized water, dried, and crushed into particles above 70 mesh; ② 75°C Next, use acetic acid to adjust the pH value of the solution containing 1.7 mg / L sodium chlorite to 4.0, and put the corn stalk particles obtained in ① into the solution at a solid-to-liquid mass ratio of 1:20 to react for 1 hour. After the reaction, add about 25 -35g sodium chlorite, and then continue to react for 1h, and the above reaction process is ultrasonical...

Embodiment 2

[0053] Example 2: Modified corn stalk cellulose adsorbent on Cu 2+ 、Ni 2+ 、Cd 2+ Adsorption test

[0054] Formulated with Cu 2+ 500mg / L of simulated wastewater 1L, the modified corn stalk cellulose adsorbent (MCC-g-GMA-DETA) 1g prepared in Example 1 was dropped into the simulated wastewater that had adjusted the pH to 4-5. Under the condition of stirring at 25°C, the adsorption was carried out for 250 minutes, and samples were taken at 5min, 10min, 15min, 20min, 30min, 45min, 60min, 90min, 120min, 180min, and 240min to detect the concentration of heavy metal ions. The adsorption curve is as follows: Figure 4 Shown (in Cu 2+ example).

[0055] Depend on image 3 It can be seen that within the first 60min, the adsorption amount increases rapidly with time; within 60-120min, the adsorption amount increases slowly with time; after 120min, the adsorption amount tends to balance. At room temperature, pH 4-5, amination modified cellulose to 500mg / L Cu 2+ The equilibrium adso...

Embodiment 3

[0059] Example 3: Modified corn stalk cellulose adsorbent for Cu in industrial wastewater 2+ 、Ni 2+ 、Cd 2+ The removal effect of

[0060] Sampling and detection of industrial wastewater in an industrial park, the pH of the wastewater was measured to be 4.8, Cu 2+The concentration is 254mg / L, Ni 2+ The concentration is 156mg / L, Cd 2+ The concentration is 78mg / L. Get this industrial wastewater 1L, drop into the modified corn straw cellulose adsorbent (MCC-g-GMA-DETA) 3g that the embodiment 1 makes, carry out adsorption under 25 ℃ of stirring conditions for 120 minutes, detect Cu 2+ 、Ni 2+ 、Cd 2+ Residual concentration, the results are shown in the table below.

[0061]

[0062] From the data in the table above, it can be seen that the modified corn stalk cellulose adsorbent (MCC-g-GMA-DETA) obtained by the present invention is applied to high-concentration Cu-containing 2+ 、Ni 2+ 、Cd 2+ In industrial wastewater, Cu 2+ The removal rate reaches 99.0%, Ni 2+ The rem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com