Method for preparing flaky TiO2/g-C3N4 heterojunction by one-step method

A g-c3n4, heterojunction technology, applied in chemical instruments and methods, catalyst activation/preparation, water/sludge/sewage treatment, etc., can solve problems such as easy recombination of photogenerated electrons and holes, and low utilization rate of solar energy , to achieve the effect of simple and quick method, low cost and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Add acetylacetone and tetrabutyl titanate in sequence to absolute ethanol at a volume ratio of 1:1:3, mix well

[0025] Get solution A;

[0026] 2) Add polyvinylpyrrolidone with a mass ratio of 8% to solution A, and completely dissolve to obtain solution B;

[0027] 3) Add melamine powder with a mass ratio of 12.5% to solution B, and stir to obtain mixed solution C;

[0028] 4) Put the mixed solution C into a 5mL syringe, install the syringe on the electrospinning device, conduct electrospinning at a voltage of 20KV, a solution supply rate of 50μL / min, and a receiving distance of 20cm, and collect the product with a stainless steel plate;

[0029] 5) After the product is dried, it is calcined at 550° C. for 4 hours in an air atmosphere;

Embodiment 2

[0031] 1) Add acetylacetone and tetrabutyl titanate in sequence to absolute ethanol at a volume ratio of 1:1:2, mix well

[0032] Get solution A;

[0033] 2) Add polyvinylpyrrolidone with a mass ratio of 10% to solution A, and completely dissolve to obtain solution B;

[0034] 3) Add melamine powder with a mass ratio of 15% to solution B, and stir to obtain mixed solution C;

[0035] 4) Put the mixed solution C into a 5mL syringe, install the syringe on the electrospinning device, conduct electrospinning at a voltage of 20KV, a solution supply rate of 50μL / min, and a receiving distance of 20cm, and collect the product with a stainless steel plate;

[0036] 5) After the product is dried, it is calcined at 550° C. for 4 hours in an air atmosphere;

Embodiment 3

[0038] 1) Add acetylacetone and tetrabutyl titanate in sequence to absolute ethanol at a volume ratio of 1:1:3, mix well

[0039] Get solution A;

[0040] 2) Add polyvinylpyrrolidone with a mass ratio of 12% to solution A, and completely dissolve to obtain solution B;

[0041] 3) Add melamine powder with a mass ratio of 17.5% to solution B, and stir to obtain mixed solution C;

[0042] 4) Put the mixed solution C into a 5mL syringe, install the syringe on the electrospinning device, conduct electrospinning at a voltage of 20KV, a solution supply rate of 50μL / min, and a receiving distance of 20cm, and collect the product with a stainless steel plate;

[0043] 5) After the product is dried, it is calcined at 550° C. for 4 hours in an air atmosphere;

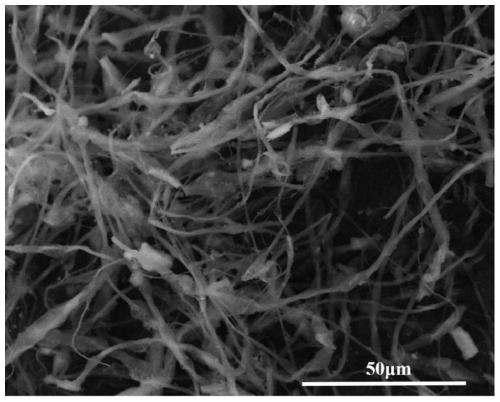

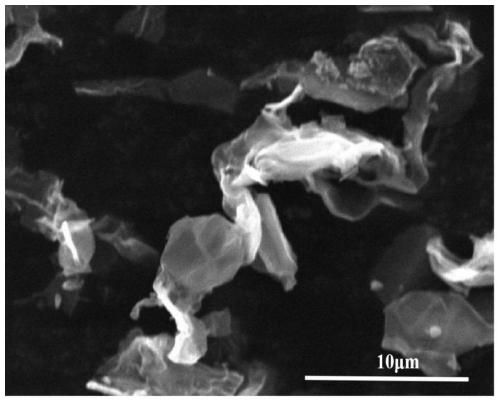

[0044] Build TiO 2 / g -C 3 N 4 heterojunction, capable of reducing TiO 2 The bandgap width can increase the light absorption range, while reducing the photogenerated electron-hole recombination efficiency and improving the ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com