Upper surface antireflective coating composition for photolithography

A technology of anti-reflection coating and composition, which is applied in the direction of anti-reflection coating, photosensitive material for optomechanical equipment, coating, etc., which can solve the problems of low transmittance, high refractive index, and large coating thickness, etc. Achieve the effects of reducing the refractive index, increasing the transmittance, and increasing the fluorine content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

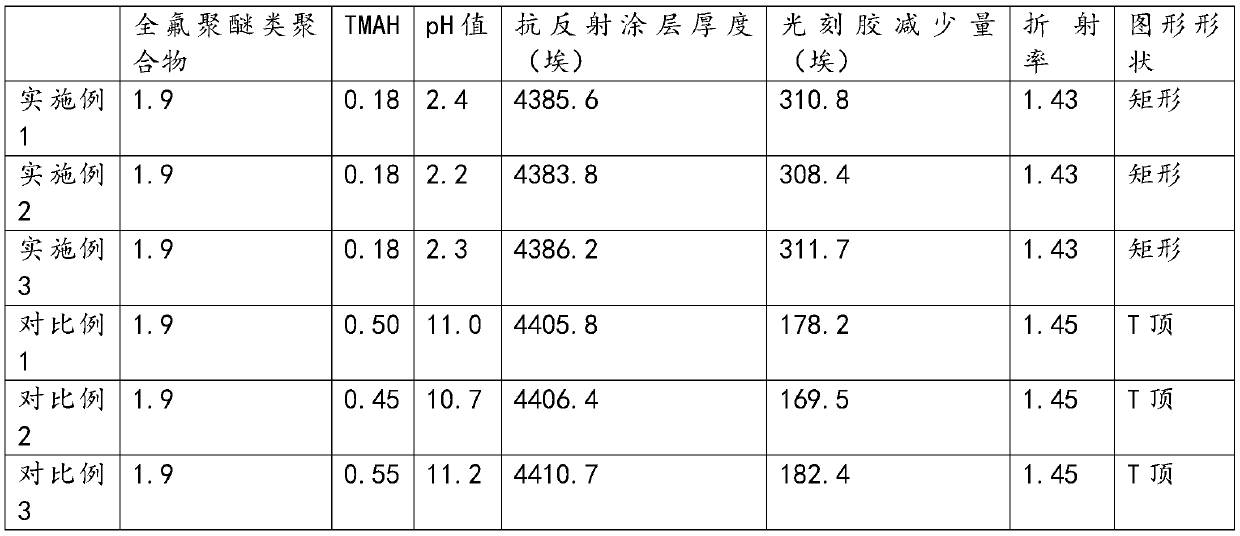

Embodiment 1

[0074] This embodiment provides a composition for semiconductor lithography anti-reflection coating, and a method for preparing the composition.

[0075] Composition preparation:

[0076] Step 1: Under room temperature, take 1.9g perfluoropolyether polymer F[CF(CF 3 )-CF 2 -O] n CF(CF 3 )-COOH (the average molecular weight is 1600), and part of the perfluoropolyether polymer F[CF(CF 3 )-CF 2 -O] n CF(CF 3 )-COOH is mixed with 10% polyvinylpyrrolidone solution to form a uniform transparent solution, wherein the molar ratio of polyvinylpyrrolidone to carboxylic acid generated by perfluoropolyether polymer is 15:1, and the molecular weight of polyvinylpyrrolidone is 5000.

[0077] Step 2: The remaining perfluoropolyether polymer F[CF(CF 3 )-CF 2 -O] n CF(CF 3 )-COOH is added to 0.18g 25% methyl ammonium hydroxide solution to form a uniform transparent solution, the carboxylic acid group generated by the perfluoropolyether polymer and the mol ratio of amine is 1:1.1, th...

Embodiment 2

[0081] Get 1.9g perfluoropolyether polymer F[CF(CF) in the present embodiment 3 )-CF 2 -O] n CF(CF 3 )-COOH (the average molecular weight is 500), under the situation that the total mass of the solution remains constant, the pH is adjusted to 2.2 by changing the consumption of fluorine-containing carboxylic acid and water, and the remaining operating steps of Example 1 are repeated.

Embodiment 3

[0083] Get 1.9g perfluoropolyether polymer F[CF(CF) in the present embodiment 3 )-CF 2 -O] n CF(CF 3 )-COOH (the average molecular weight is 4000), under the situation that the total mass of the solution remains constant, adjust the pH to 2.3 by changing the consumption of fluorine-containing carboxylic acid and water, and repeat the remaining operating steps of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com