A kind of preparation method of rod-shaped α-calcium sulfate hemihydrate whisker

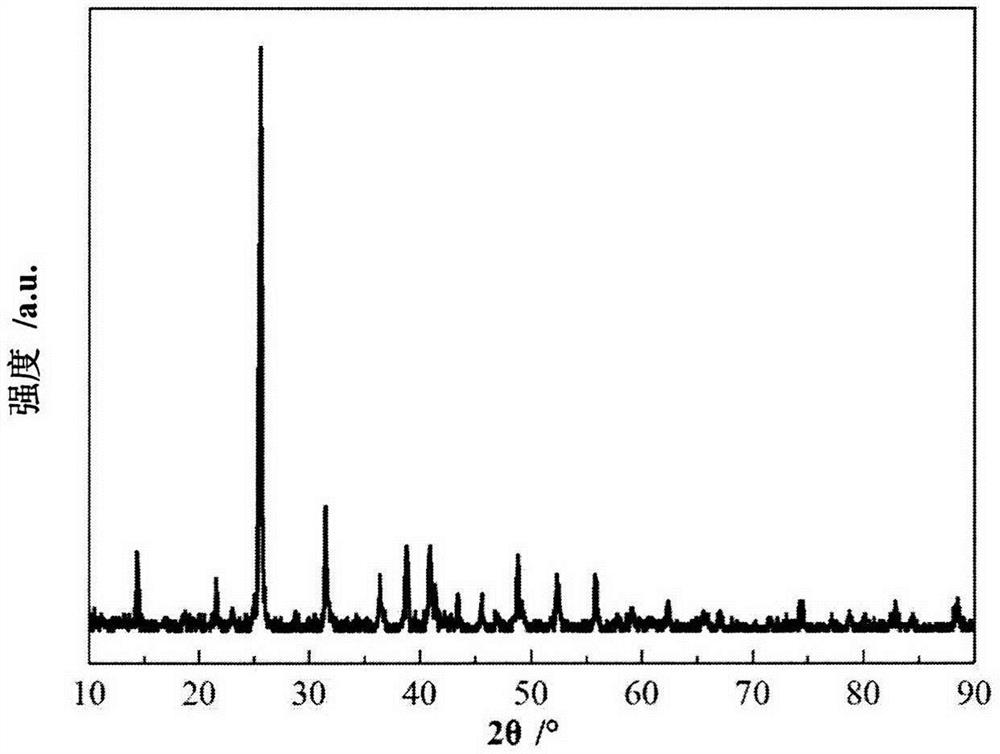

A calcium sulfate hemihydrate and rod-shaped technology is applied in the field of preparation of rod-shaped α-calcium sulfate hemihydrate whiskers, which can solve the problems of incomplete crystal form and low purity of calcium sulfate whiskers, and achieve a green, pollution-free and repeatable preparation process. The effect of good performance and low synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

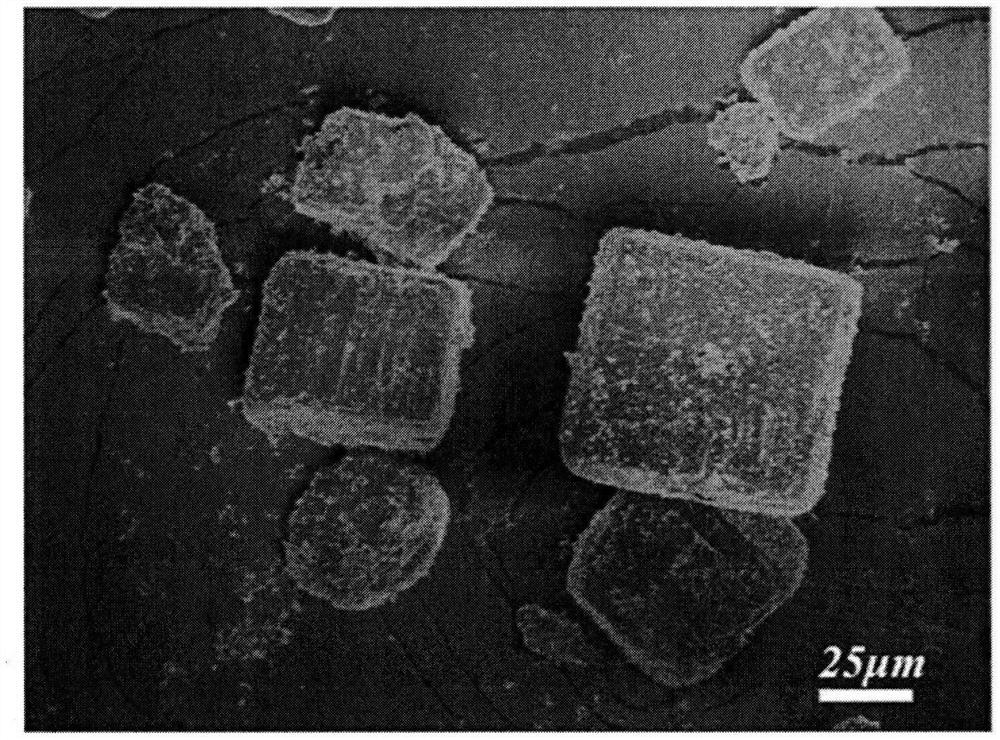

[0052] This embodiment provides a method for preparing rod-shaped α-calcium sulfate hemihydrate whiskers, which includes the following steps:

[0053] 1) Take the solid waste of sodium sulfate, calcinate in a calciner to remove organic residues, calcining temperature 700℃, calcining time 3 hours; after calcining, dissolve the calcined sodium sulfate with water, filter to remove inorganic insolubles, and make 2.0 mol / L sodium sulfate aqueous solution;

[0054] 2) Measure 300ml (0.60mol) of 2.0mol / L sodium sulfate aqueous solution into the reaction vessel, then add 22.58g sodium hydrogen phthalate, heat and stir to raise to 100℃, slowly add 4.5mol / L calcium chloride aqueous solution 133ml (0.60mol), the feeding speed is 7.5ml / min, after the calcium chloride aqueous solution is added, continue to keep stirring at 100°C for 2h;

[0055] 3) After the reaction is completed, let it stand and age for 30h to obtain the crude rod-shaped α-calcium sulfate hemihydrate whisker. Wash the rod-shap...

Embodiment 2

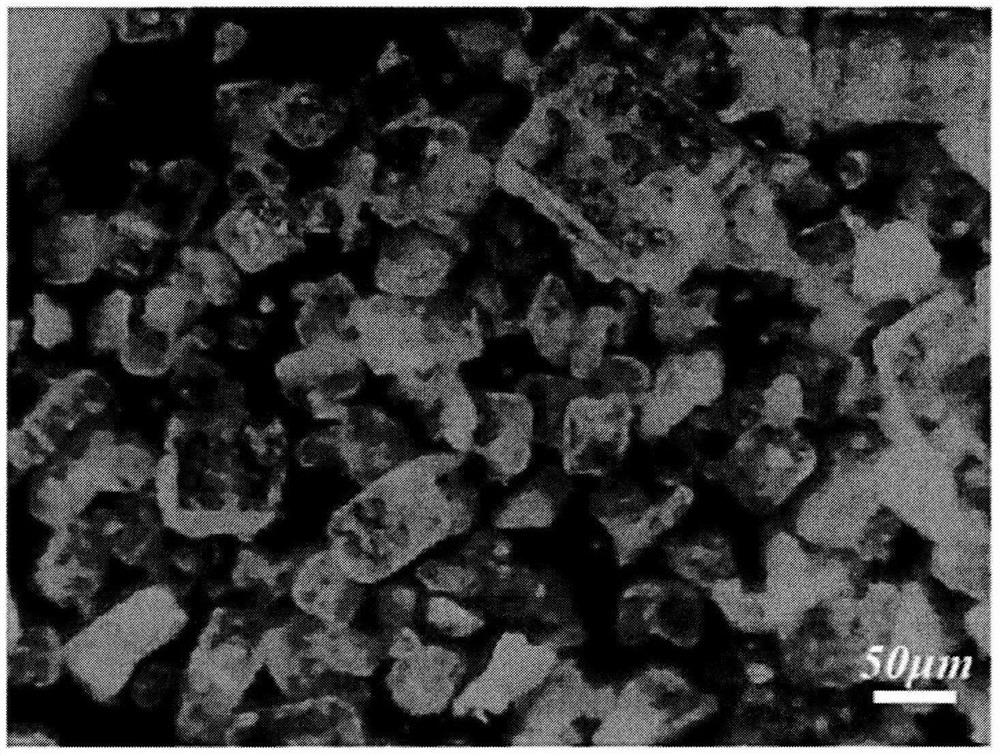

[0061] This embodiment provides a method for preparing rod-shaped α-calcium sulfate hemihydrate whiskers, which includes the following steps:

[0062] 1) Take sodium sulfate solid waste, calcined in a calciner to remove organic residues, calcining temperature is 800℃, calcining time is 1 hour; after calcining, dissolve the calcined sodium sulfate with water, filter to remove inorganic insolubles to make 2.0 mol / L sodium sulfate aqueous solution;

[0063] 2) Measure 335ml (0.67mol) of 2.0mol / L sodium sulfate aqueous solution in the reaction vessel, then add 20.28g of phthalic anhydride, heat and stir to raise the temperature to 105°C, slowly add 117ml (0.70mol) of 6mol / L calcium nitrate aqueous solution ), the feeding speed is 7.5ml / min, after the calcium nitrate aqueous solution has been fed, continue to stir and react at 105°C for 3h;

[0064] 3) After the reaction is completed, let stand and age for 15 hours to obtain the crude α-calcium sulfate hemihydrate whiskers. Wash the crud...

Embodiment 3

[0067] This embodiment provides a method for preparing rod-shaped α-calcium sulfate hemihydrate whiskers, which includes the following steps:

[0068] 1) Take sodium sulfate solid waste, calcined in a calciner to remove organic residues, calcining temperature is 500℃, calcining time is 24 hours; after calcining, dissolve the calcined sodium sulfate with water, filter to remove inorganic insolubles to make 1.0 mol / L sodium sulfate aqueous solution;

[0069] 2) Measure 400ml (0.4mol) of 1.0mol / L sodium sulfate aqueous solution in the reaction vessel, then add 1.15g of sodium benzoate, heat and stir to raise the temperature to 90℃, slowly add 3.5mol / L calcium nitrate aqueous solution 91.4ml (0.32mol) , The feeding rate is 7.5ml / min, after the calcium nitrate aqueous solution is added, continue to keep stirring at 90°C for 6h;

[0070] 3) After the reaction is completed, let stand for 24 hours to obtain the crude rod-shaped α-calcium sulfate hemihydrate whisker. Wash the rod-shaped crud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com