Blast bead sugar and preparation method thereof

A technology of popping bead and wrapping layer, applied in the field of popping bead candy, it can solve the problem of single variety, and achieve the effects of low water content, strong elasticity and high nutritional value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

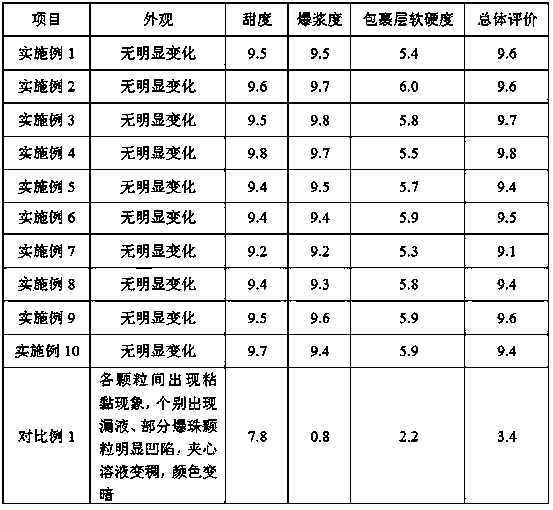

Examples

Embodiment 1

[0026] In this example, popcorn candy was prepared according to the following method:

[0027] (1) Coating layer formula:

[0028] Tapioca starch 20kg Glycerin 7kg

[0029] Purified water 21.6kg Sodium carboxymethyl cellulose 0.1kg

[0030] Sweet Orange Flavor 11g Sucralose 5.5g

[0031] Carotene 15g

[0032] (2) Sandwich formula:

[0033] Flaxseed Oil 0.54kg DHA Algae Oil 0.27kg

[0034] Soybean oil 8.95kg Pueraria powder 0.15kg

[0035] Peppermint essential oil 0.15kg Sucralose 0.01kg

[0036] Sodium carboxymethyl cellulose 0.01kg

[0037] (3) Preparation of the sandwich solution: Mix the linseed oil, DHA algae oil, and appropriate amount of soybean oil to make a solution; pour the mixed oil solution into the liquid mixing tank, and add pueraria powder, peppermint essential oil, and triclosan Sucrose, mixed for 25 minutes; weigh the sodium carboxymethyl cellulose of the formula, pour it into the liquid mixing tank, start stirring, and stop stirring after the sodium c...

Embodiment 2

[0043] Prepare quick-fried pearl candy according to the method of embodiment 1, difference is:

[0044] (1) Coating layer formula:

[0045] Tapioca starch 10kg Corn starch 10kg

[0046] Glycerin 7kg Purified water 21.6kg

[0047] Propylene Glycol Alginate 0.1kg Strawberry Flavor 11g

[0048] Glucose 5.5g Carmine 15g

[0049] (2) Sandwich formula:

[0050] Flaxseed Oil 0.54kg DHA Algae Oil 0.27kg

[0051] Sunflower Oil 8.95kg Cherry Flavor 0.15kg

[0052] Menthol 0.15kg Xylitol 0.02kg

[0053] Propylene glycol alginate 0.01kg Lactic acid 0.02kg

Embodiment 3

[0055] Prepare quick-fried beads according to the method of Example 1, the difference is:

[0056] (1) Coating layer formula:

[0057] Hydroxypropyl Tapioca Starch 18kg Tapioca Starch 3.2kg

[0058] Glycerin 7.2kg Purified water 22.0kg

[0059] Gellan Gum 0.1kg Lime Flavor 11g

[0060] Maltose 5.5g Chlorophyll 10g

[0061] (2) Sandwich formula:

[0062] Flaxseed Oil 0.54kg DHA Algae Oil 0.27kg

[0063] Camellia oil 8.96kg Taurine 0.15kg

[0064] Menthol 0.15kg Acesulfame K 0.01kg

[0065] Gum Arabic 0.005kg Gellan Gum 0.01kg

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com