Ammonia synthesis method by coupling solid oxide electrolysis with fossil fuel ammonia synthesis

A solid oxide and fossil fuel technology, applied in the field of ammonia synthesis, can solve problems such as high energy consumption and high carbon emissions, and achieve the effects of reducing carbon emissions, realizing recycling, and realizing carbon resource recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

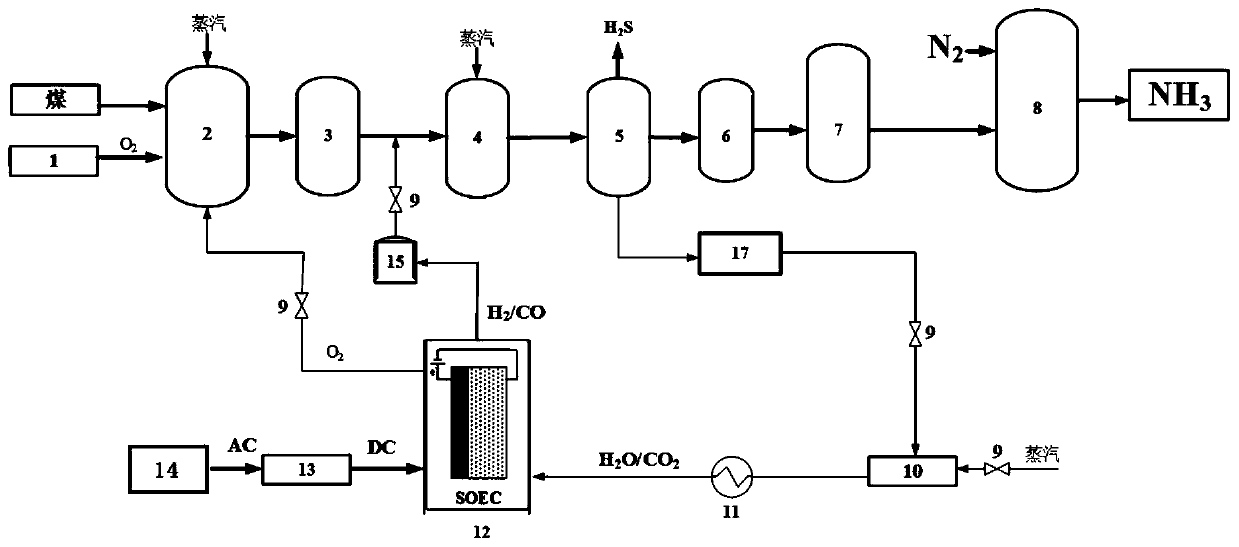

[0038] This embodiment provides a method for synthesizing ammonia in which renewable energy is used to drive a solid oxide electrolytic cell coupled with a fossil fuel ammonia synthesis system. Among them, the coal low-pressure ammonia synthesis process and the solid oxide electrolytic cell (SOEC) are used to co-electrolyze CO 2 / H 2 O integrated synthesis of ammonia, combined with the following figure 1 The present invention will be described in detail with specific examples, but the scope of the present invention will not be limited thereby.

[0039] Such as figure 1 As shown, the coal low-pressure ammonia synthesis system is simplified into air separation unit 1, coal gasification unit 2, desulfurization and dust removal unit 3, water-gas shift unit 4, desulfurization and decarbonization unit 5, methanolation unit 6, methanation unit 7, ammonia synthesis unit 8, etc. . The raw air passes through the air separation unit 1, and is separated by low temperature and pressure...

Embodiment 2

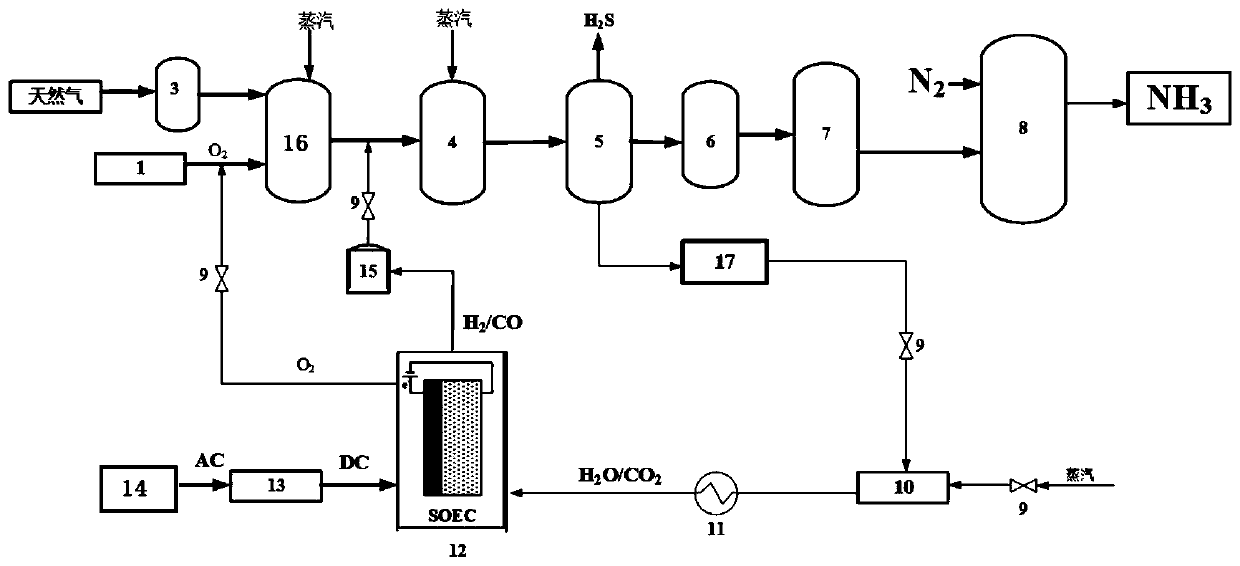

[0048] This embodiment provides a method for synthesizing ammonia by using renewable energy to drive a solid oxide electrolytic cell. Among them, the natural gas ammonia synthesis process and the solid oxide electrolysis cell (SOEC) are used to co-electrolyze CO 2 / H 2 O integrated synthesis of ammonia, combined with the following figure 2 The present invention will be described in detail with specific examples, but the scope of the present invention will not be limited thereby.

[0049] Such as figure 2 As shown, the ammonia synthesis system from natural gas is simplified into air separation unit 1, desulfurization and dust removal unit 3, natural gas reforming unit 16, water-gas shift unit 4, desulfurization and decarbonization unit 5, methanolation unit 6, methanation unit 7, ammonia synthesis unit 8, etc. . The raw air passes through the air separation unit 1, and is separated by low temperature and pressure to obtain high-purity oxygen with a concentration higher th...

Embodiment 3

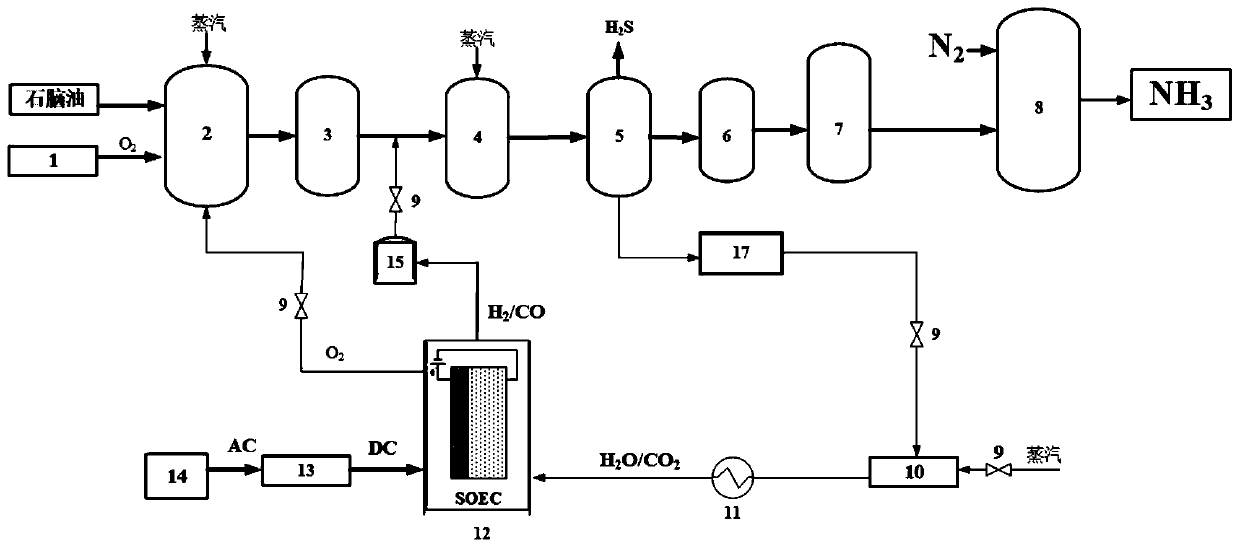

[0058] This embodiment provides a method for synthesizing ammonia by using renewable energy to drive a solid oxide electrolytic cell. Among them, the naphtha synthesis ammonia process and the solid oxide electrolytic cell (SOEC) electrolysis of H 2 O integrated synthesis of ammonia, combined with the following image 3 The present invention will be described in detail with specific examples, but the scope of the present invention will not be limited thereby.

[0059] Such as image 3As shown, the naphtha synthesis ammonia system is simplified into air separation unit 1, naphtha gasification unit 2, desulfurization and dust removal unit 3, water gas shift unit 4, desulfurization and decarbonization unit 5, methanolation unit 6, methanation unit 7, ammonia synthesis unit 8 and other links. The raw air passes through the air separation unit 1, and is separated by low temperature and pressure to obtain high-purity oxygen with a concentration higher than 99.5%. Naphtha undergoe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com