Method for preparing bimetallic oxide nanoparticles

A bimetallic oxide, nanoparticle technology, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of poor crystallinity, lack of functional groups on the surface of nanoparticles, and uneven morphology and size of MWOX nanoparticles. Achieving the effect of high efficiency, controllable size and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In view of the problems of uneven size, lack of functional groups on the surface, and poor material stability in the preparation of double metal oxide nanoparticles by chemical precipitation in the prior art, this application adopts the solvothermal method of pyrolysis to efficiently and controllably prepare a uniform size, stable Double metal oxide nanoparticles with good properties and rich surface functional groups. Specifically, the embodiment of the present invention discloses a method for preparing double metal oxide nanoparticles as shown in formula (I), comprising the following steps:

[0035] A) Mix W source and high-boiling point organic solvent, heat to 100-160°C, add oleic acid and oleylamine, and obtain the primary reactant after reaction;

[0036] B) heating the primary reactants to 240-320°C, adding M source, and obtaining double metal oxide nanoparticles after reaction;

[0037] MWO X (I);

[0038] Wherein, M is selected from one of Mn, Fe, Co, Ni, C...

Embodiment 1

[0048] Example 1MnWO X nanoparticles

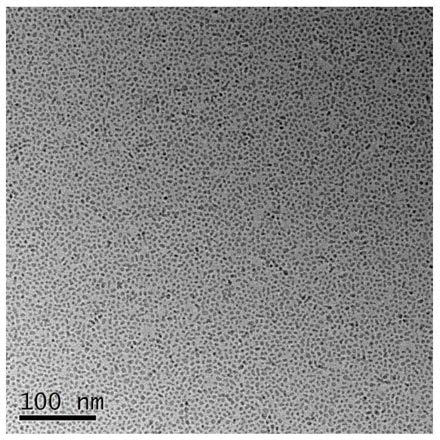

[0049] Add raw material precursor tungsten hexacarbonyl and high boiling point mixed solvent dibenzyl ether / dodecanol into the reactor, heat the reaction system to 100-160°C under the protection of nitrogen, add oleic acid and oleylamine (organic solvent A, oleic acid , the mol ratio of oleylamine is: 1:0.03~0.15:0.03~0.15); Continue heating reaction system to 240~320 ℃, add another raw material precursor manganese acetylacetonate powder (combined raw material precursor mole The ratio is 1:0.5~5); react fully for 0.5~4 hours, stop heating, and wait for the temperature of the reaction system to drop to room temperature; add excess ethanol to the product for precipitation, centrifuge to take the precipitate and wash it repeatedly with cyclohexane to obtain granular Double metal oxide MnWO with a diameter of about 6 nm X nanoparticles.

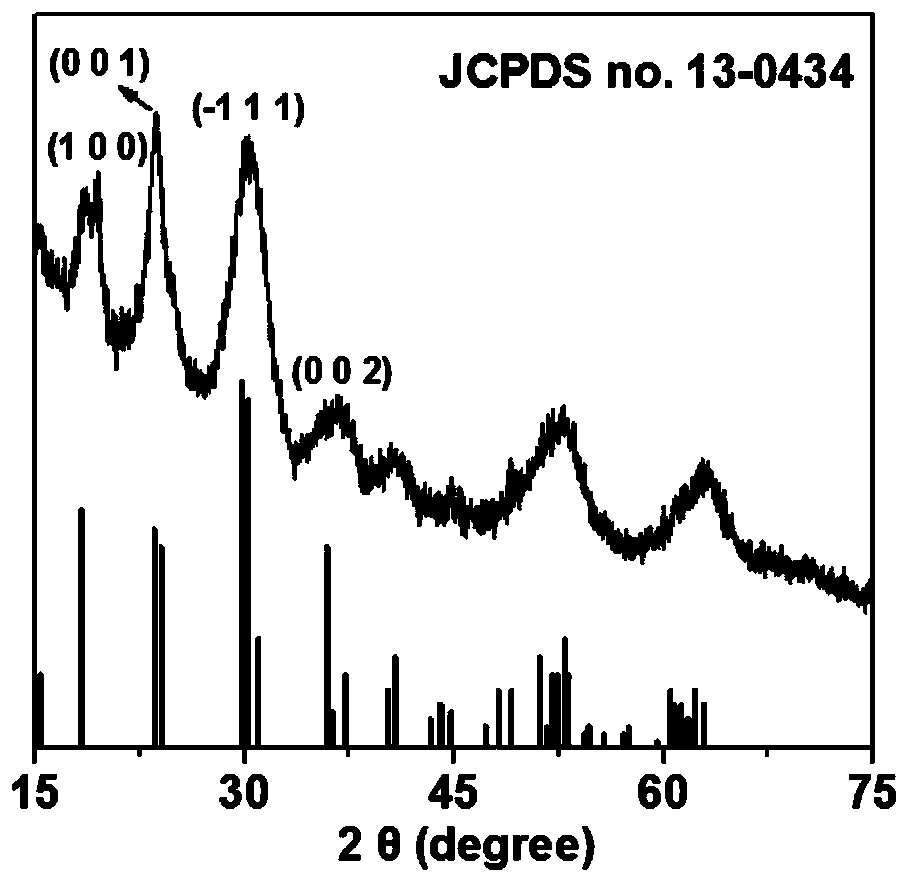

[0050] figure 1 is a synthetic double metal oxide MnWO X The X-ray diffraction spectrum of nanoparti...

Embodiment 2

[0052] Example 2: FeWO X nanoparticles

[0053] Add raw material precursor tungsten hexacarbonyl and high boiling point mixed solvent dibenzyl ether / dodecanol into the reactor, heat the reaction system to 100-160°C under the protection of nitrogen, add oleic acid and oleylamine (organic solvent A, oleic acid , the mol ratio of oleylamine is: 1:0.03~0.15:0.03~0.15); Continue to heat the reaction system to 240~320 ℃, add another raw material precursor iron acetylacetonate powder (combined raw material precursor mole The ratio is 1:0.5~5); react fully for 0.5~4 hours, stop heating, and wait for the temperature of the reaction system to drop to room temperature; add excess ethanol to the product for precipitation, centrifuge to take the precipitate and wash it repeatedly with cyclohexane to obtain granular Double metal oxide FeWO with a diameter of about 20 nm X (3.5<X<4) Nanoparticles.

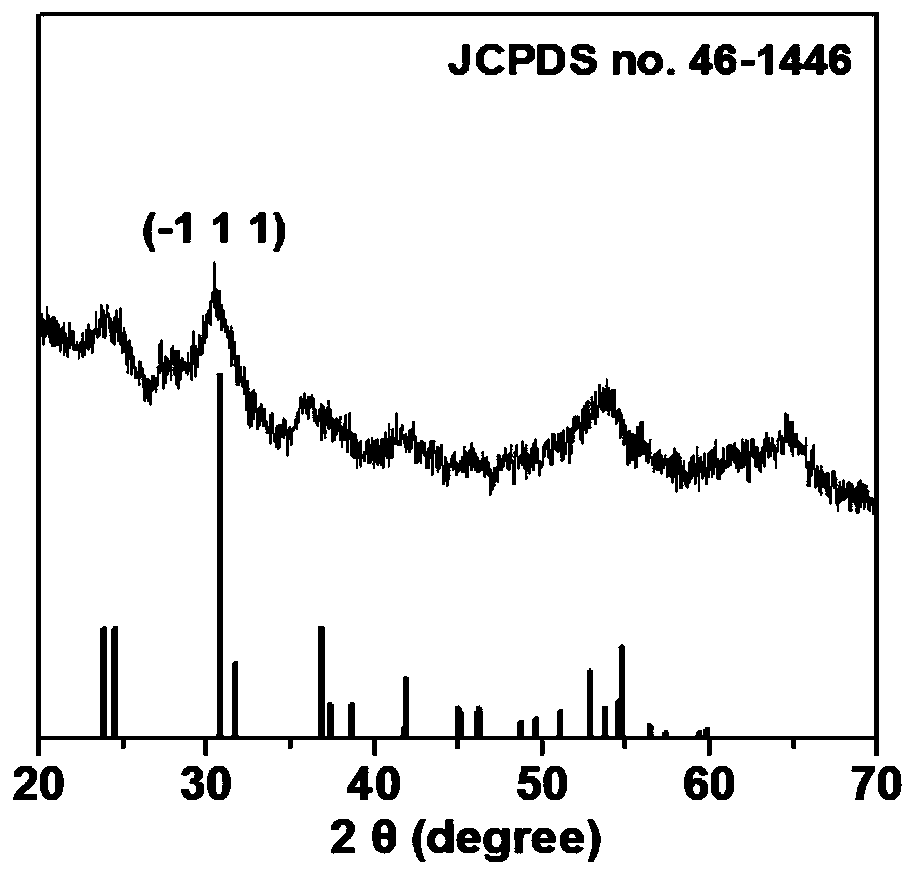

[0054] image 3 is a synthetic double metal oxide FeWO X The X-ray diffraction spectrum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com