High performance composite graphene electrically-conducting paint

A technology of composite graphene and conductive coatings, applied in conductive coatings, epoxy resin coatings, coatings, etc., can solve the problems of insufficient electrical conductivity of conductive coatings, poor impact resistance of mechanical performance coatings, etc., and achieve improved mechanical properties and low price Effect of low cost and uniform surface resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

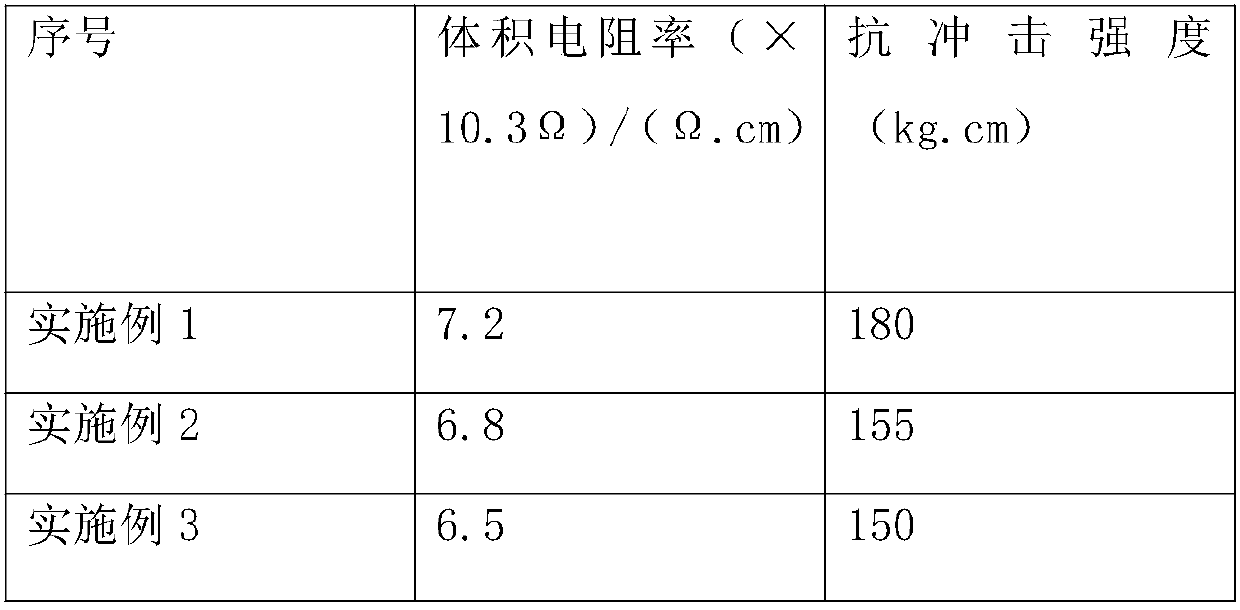

Examples

Embodiment 1

[0020] The invention provides a high-performance composite graphene conductive coating. The components of the coating are calculated according to the weight percentage: 10-15% of potassium silicate, 3-10% of water-based epoxy resin, and 1-2.5% of graphene oxide. , 5-10% tin dioxide particles, 8-10% montmorillonite, 2.5-2% sodium lignosulfonate, 3.5-5% additives, 10-15% inorganic metal copper particles, 8-15% inorganic metal silver particles 10%, inorganic metal gold particles 5-3%, inorganic silicon dioxide particles 5-7%, neutralizing agent propanolamine 2-5%, ethanol 2-5% and distilled water 35-45%.

[0021] Specific steps are as follows:

[0022] Step 1: putting the graphene oxide and the sodium lignosulfonate into distilled water, and stirring to obtain a graphene oxide dispersion;

[0023] Step 2: Put the potassium silicate and the water-based epoxy resin into the graphene oxide dispersion, add the montmorillonite and the additive after stirring, and continue stirring to...

Embodiment 2

[0027] The invention provides a high-performance composite graphene conductive coating. The components of the coating are calculated according to the weight percentage: 10-15% of potassium silicate, 3-10% of water-based epoxy resin, and 1-2.5% of graphene oxide. , montmorillonite 8-10%, sodium lignosulfonate 2.5-2%, additives 3.5-5%, inorganic metal copper particles 10-15%, inorganic silica particles 5-7%, neutralizer propanol Amine 2-5%, ethanol 2-5% and distilled water 45-50%.

[0028] Specific steps are as follows:

[0029] Step 1: putting the graphene oxide and the sodium lignosulfonate into distilled water, and stirring to obtain a graphene oxide dispersion;

[0030] Step 2: Put the potassium silicate and the water-based epoxy resin into the graphene oxide dispersion, add the montmorillonite and the additive after stirring, and continue stirring to obtain a mixed solution;

[0031] Step 3: adding the inorganic metal copper particles and the inorganic silicon dioxide par...

Embodiment 3

[0034] The invention provides a high-performance composite graphene conductive coating. The components of the coating are calculated according to the weight percentage: 10-15% of potassium silicate, 3-10% of water-based epoxy resin, and 1-2.5% of graphene oxide. , 5-10% tin dioxide particles, 8-10% montmorillonite, 2.5-2% sodium lignosulfonate, 3.5-5% additives, 10-15% inorganic metal copper particles, 5% inorganic silica particles ~7%, neutralizing agent propanolamine 2~5%, ethanol 2~5% and distilled water 45~50%.

[0035] Specific steps are as follows:

[0036] Step 1: putting the graphene oxide and the sodium lignosulfonate into distilled water, and stirring to obtain a graphene oxide dispersion;

[0037] Step 2: Put the potassium silicate and the water-based epoxy resin into the graphene oxide dispersion, add the montmorillonite and the additive after stirring, and continue stirring to obtain a mixed solution;

[0038] Step 3: adding the tin dioxide nanoparticles into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com