Preparation method of laminated electrolytic oxidation water electrode

An electrolytic oxidation and water electrode technology, which is applied in the plating of superimposed layers, chemical instruments and methods, and electrolytic coatings, etc. problem, to achieve the effect of excellent diffusible bacteriostatic ability, excellent electrical properties and electrolytic ability, and excellent bacteriostatic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

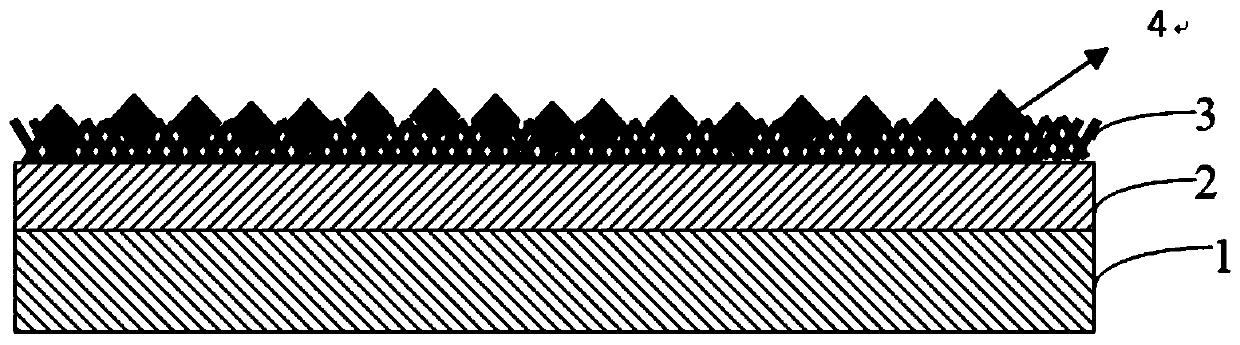

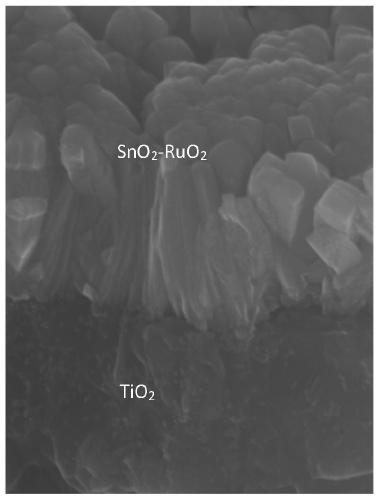

Image

Examples

Embodiment 1

[0040] 1) Micro-arc oxidation treatment: dissolving disodium edetate and sodium hydroxide in water to form a mixed solution, the concentration of disodium edetate in the mixed solution is 0.1mol / L, and the concentration of sodium hydroxide is 0.1mol / L. The mixed solution is used as the electrolyte, the titanium sample is used as the anode, and the stainless steel plate is used as the cathode; the electrolyte is added to the electrolytic container, and the titanium sample is placed in the electrolyte at 25°C for micro-arc oxidation. Layer micro-arc oxidation adopts pulse voltage, the positive voltage is 300V, the negative voltage is 20V, the pulse frequency of micro-arc oxidation is 600Hz, the duty cycle of micro-arc oxidation is 4%, the time of micro-arc oxidation is 1min, and titanium dioxide is formed on the surface of titanium. The micro-arc oxidation coating with a microporous structure is dried to obtain a titanium electrode with a micro-arc oxidation titanium coating on ...

Embodiment 2

[0045] 1) Micro-arc oxidation treatment: dissolving disodium edetate and sodium hydroxide in water to form a mixed solution, the concentration of disodium edetate in the mixed solution is 0.3mol / L, and the concentration of sodium hydroxide is 0.3mol / L. The mixed solution is used as the electrolyte, the titanium sample is used as the anode, and the stainless steel plate is used as the cathode; the electrolyte is added to the electrolytic container, and the titanium sample is placed in the electrolyte at 35°C for micro-arc oxidation. Layer micro-arc oxidation adopts pulse voltage, the positive voltage is 500V, the negative voltage is 30V, the pulse frequency of micro-arc oxidation is 800Hz, the duty cycle of micro-arc oxidation is 5%, the time of micro-arc oxidation is 6min, and titanium dioxide is formed on the surface of titanium. A micro-arc oxidation coating with a microporous structure is dried to obtain a titanium electrode with a micro-arc oxidation titanium coating on th...

Embodiment 3

[0049] 1) Micro-arc oxidation treatment: dissolving disodium edetate and sodium hydroxide in water to form a mixed solution, the concentration of disodium edetate in the mixed solution is 0.4mol / L, and the concentration of sodium hydroxide is 0.5mol / L. The mixed solution is used as the electrolyte, the titanium sample is used as the anode, and the stainless steel plate is used as the cathode; the electrolyte is added to the electrolytic container, and the titanium sample is placed in the electrolyte at 80°C for micro-arc oxidation. Layer micro-arc oxidation adopts pulse voltage, the positive voltage is 450V, the negative voltage is 60V, the pulse frequency of micro-arc oxidation is 900Hz, the duty cycle of micro-arc oxidation is 7%, the time of micro-arc oxidation is 6min, and titanium dioxide is formed on the surface of titanium. The micro-arc oxidation coating with a microporous structure is dried to obtain a titanium electrode with a micro-arc oxidation titanium coating on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com