Modified positive electrode material and preparation method thereof

A positive electrode material and modification technology, applied in the direction of positive electrode, active material electrode, battery electrode, etc., can solve the problems of poor rate performance and poor cycle performance, so as to avoid direct contact, increase transmission rate, improve cycle performance and rate performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

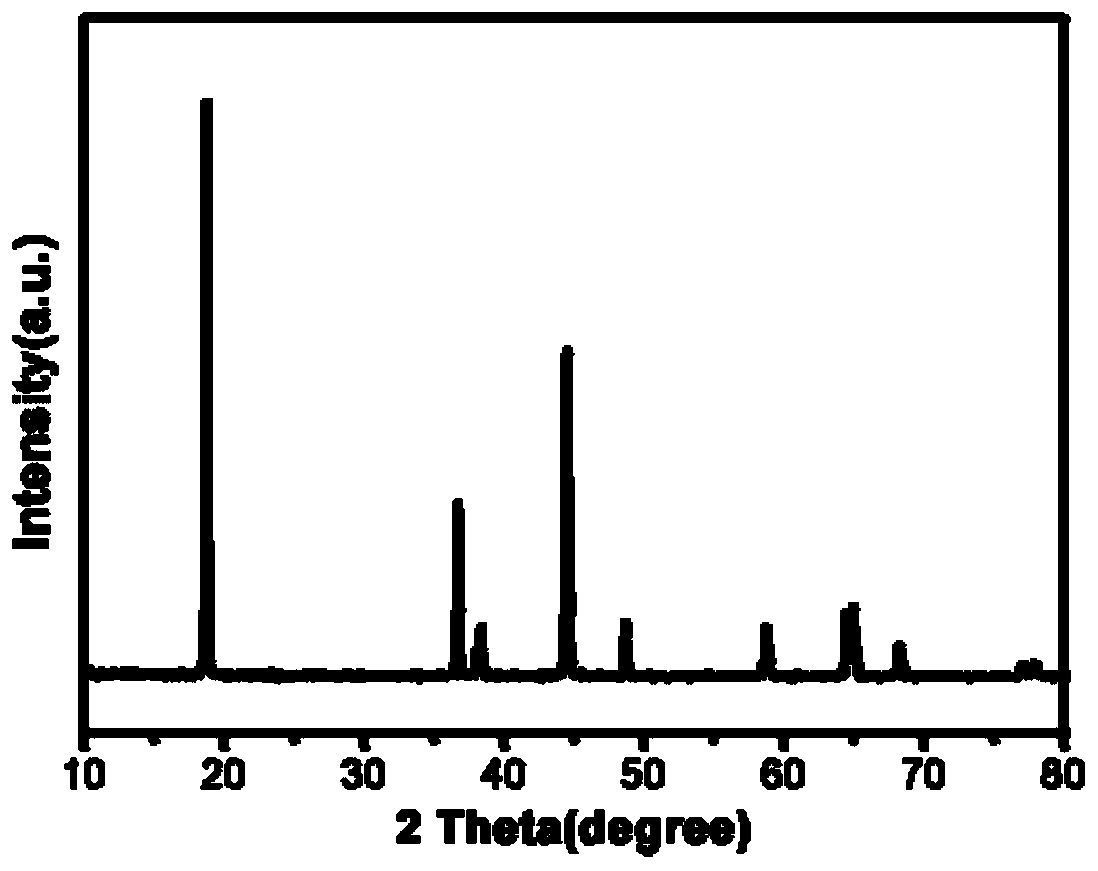

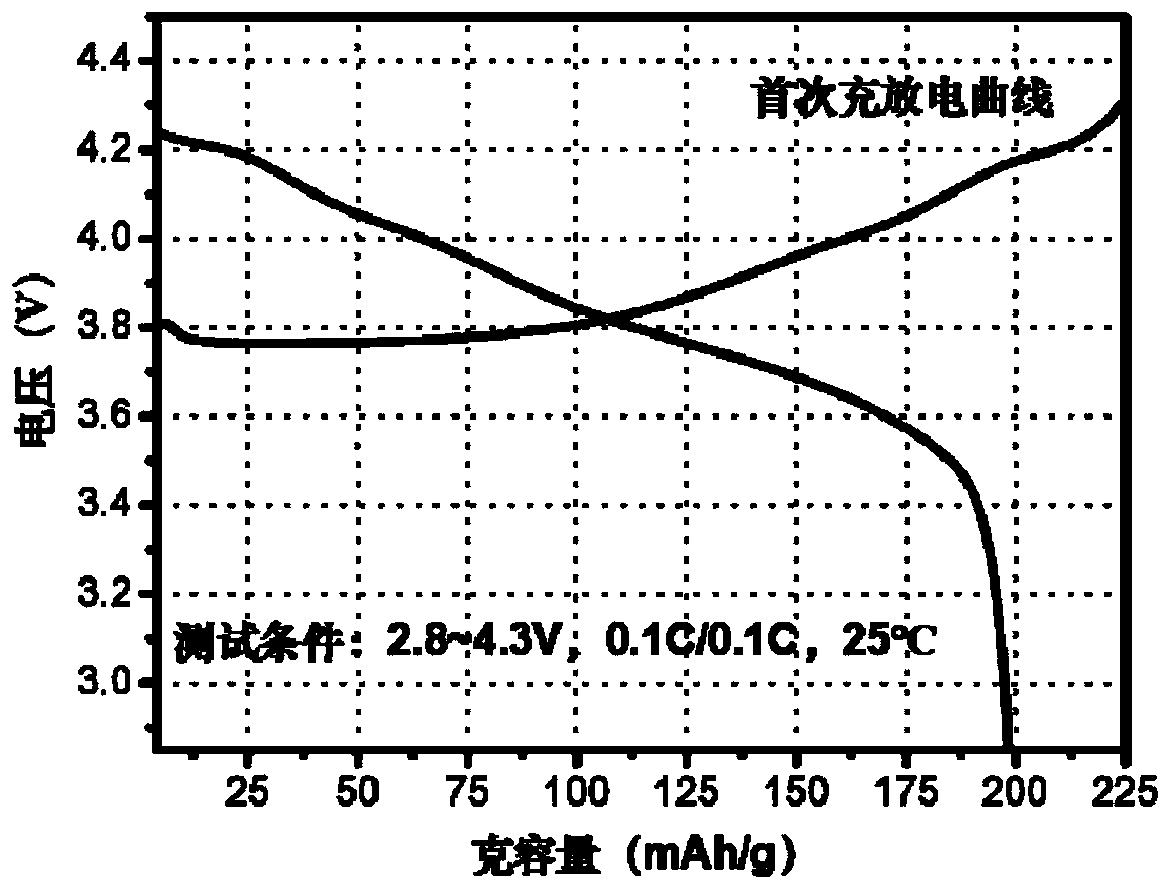

[0038]This embodiment provides a modified positive electrode material, which is prepared by the following method:

[0039] S1: Add the nickel-cobalt-lithium-aluminate positive electrode material into the container containing the copper sulfate solution, use a double planetary mixer with a revolution line speed of 2m / s and a rotation line speed of 10m / s, and the stirring time is 300min, so that the material is fully slurried, Use a peristaltic pump to input the slurry into the spray dryer for spray drying (the inlet temperature is 300°C, the outlet temperature is 110°C), and the dried powder is placed in the muffle furnace at a rate of 5°C / min. Raise the temperature to 500°C, keep it warm for 5 hours in an oxygen atmosphere, then cool down to room temperature with the furnace, grind, pulverize, and sieve to obtain the NCA@CuO cathode material;

[0040] S2: Dissolve glucose evenly in deionized water at a temperature of 40°C, prepare a solution with a concentration of 0.2mol / L, t...

Embodiment 2

[0044] This embodiment provides a modified positive electrode material, which is prepared by the following method:

[0045] S1: Add the nickel-cobalt-lithium-aluminate positive electrode material into the container containing the copper nitrate solution, use a double planetary mixer at a linear speed of 4m / s for revolution and 20m / s for rotation, and stir for 100min to make the material fully slurried. Use a peristaltic pump to input the slurry into the spray dryer for spray drying (the inlet temperature is 350°C, the outlet temperature is 120°C), and the dried powder is placed in the muffle furnace with a temperature increase of 3°C / min. Raise the temperature to 550°C, keep it warm for 6 hours in an oxygen atmosphere, then cool down to room temperature with the furnace, grind, pulverize, and sieve to obtain the NCA@CuO cathode material;

[0046] S2: Dissolve sucrose evenly in deionized water at a temperature of 50°C, prepare a solution with a concentration of 0.5mol / L, then p...

Embodiment 3

[0049] This embodiment provides a modified positive electrode material, which is prepared by the following method:

[0050] S1: Add the nickel-cobalt-lithium-aluminate positive electrode material into a container containing copper chloride solution, use a double planetary mixer with a revolution linear speed of 4m / s and a rotation linear speed of 25m / s, and stir for 60 minutes to fully slurry the material , use a peristaltic pump to input the slurry into the spray dryer for spray drying (the inlet temperature is 400°C, the outlet temperature is 80°C), and the dried powder is placed in the muffle furnace at a rate of 10°C / min. The heating rate was raised to 400°C, and the temperature was kept for 3 hours in an oxygen atmosphere, and then cooled to room temperature with the furnace, and then the NCA@CuO cathode material was obtained after grinding, crushing, and sieving;

[0051] S2: Dissolve glucose evenly in deionized water at a temperature of 60°C, prepare a solution with a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| D50 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com