Complete granulated feed capable of increasing slaughtering properties and meat quality of drylot-fed Tan sheep and preparation method and application of complete granulated feed

A technology of slaughtering performance and pellet feed, applied in application, animal feed, animal feed, etc., can solve the problems of accelerated fat deposition of Tan sheep and decline of Tan sheep meat quality, so as to improve slaughter performance, solve the shortage of forage, and improve the quality of mutton meat. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Weigh the following raw materials by weight: 52 parts of corn, 12 parts of soybean meal, 8 parts of cotton meal, 9.5 parts of alfalfa powder, 8 parts of soybean hulls, 5 parts of apple pomace, 0.45 part of rumen-passed lysine, 0.31 part of methionine, N - 0.2 parts of carbamoyl glutamic acid, 0.4 parts of Saccharomyces cerevisiae culture, 0.03 parts of compound enzyme preparation, 0.95 parts of stone powder, 0.35 parts of baking soda, 1.5 parts of conjugated linoleic acid, 0.8 parts of sodium chloride, propionic acid type anti 0.03 parts of mold agent, 0.05 parts of montmorillonite, 0.03 parts of sweetener, 0.2 parts of trace element additives, 0.2 parts of multivitamins, etc.

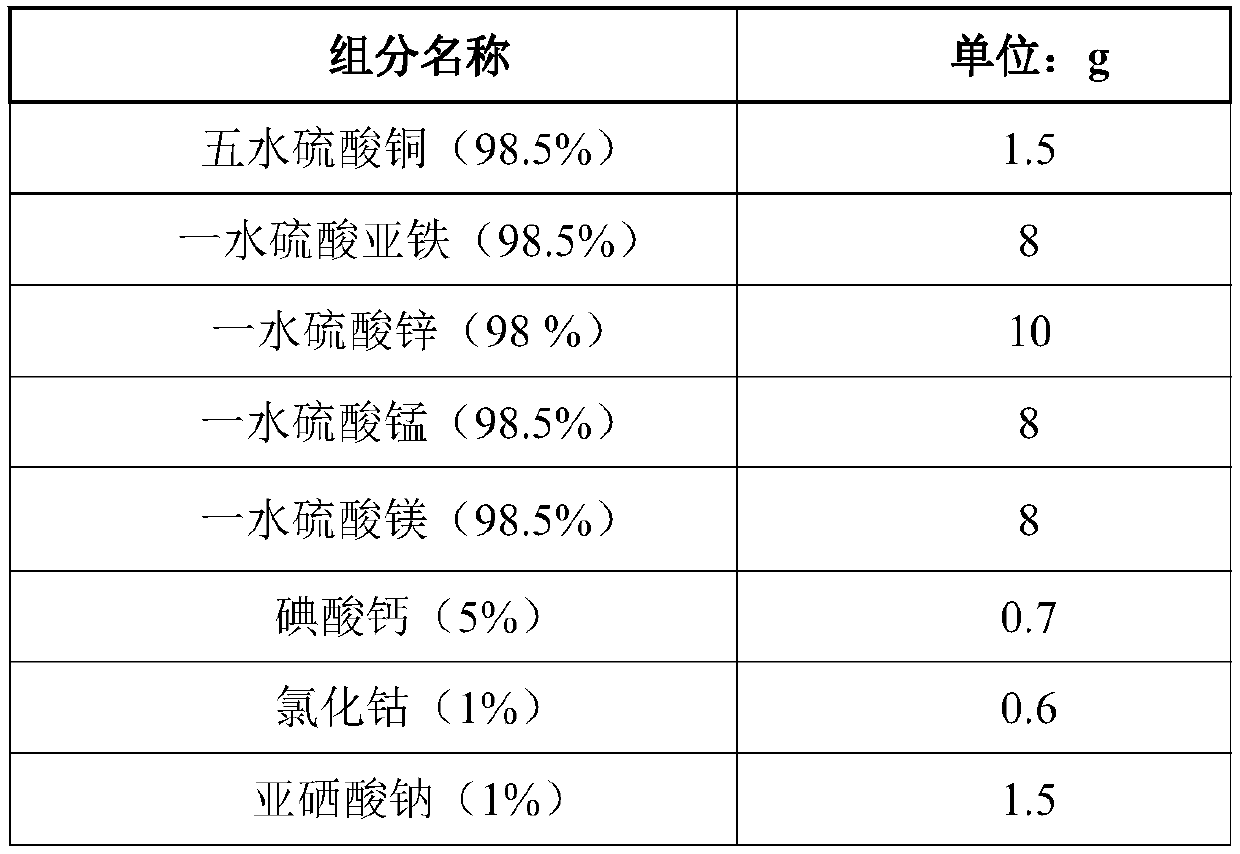

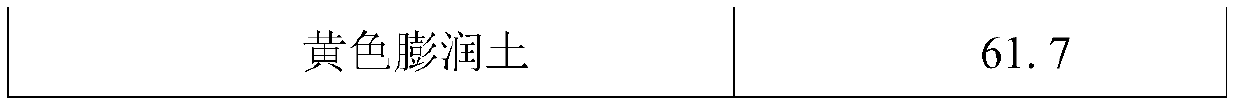

[0033] Among them, the trace element additive is composed of the composition in Table 1, and the multivitamin is composed of the composition in Table 2.

[0034] Table 1 Trace element additive formula table

[0035]

[0036]

[0037] Table 2 Compound vitamin formula table

[0038] ...

Embodiment 2

[0041] Weigh the following raw materials by weight: 56 parts of corn, 12 parts of soybean meal, 6.5 parts of cotton meal, 10 parts of alfalfa powder, 5 parts of soybean hulls, 5 parts of apple pomace, 0.3 part of rumen-passed lysine, 0.16 part of methionine, N - 0.25 parts of carbamoyl glutamic acid, 0.4 parts of Saccharomyces cerevisiae culture, 0.03 parts of compound enzyme preparation, 0.85 parts of stone powder, 0.4 parts of baking soda, 1.8 parts of conjugated linoleic acid, 0.8 parts of sodium chloride, propionic acid type anti 0.03 parts of mold agent, 0.05 parts of montmorillonite, 0.03 parts of sweetener, 0.2 parts of trace element additives, 0.2 parts of multivitamins, etc.

[0042] Wherein the trace element additive is composed of the Table 1 distribution in Example 1, and the multivitamin is composed of the Table 2 distribution in Example 1.

[0043] Preparation method: crush corn, sieve with double-layer initial cleaning sieve, the upper and lower meshes of the do...

Embodiment 3

[0045] The feed feeding mode of the present invention is compared with the existing Tan sheep feeding mode.

[0046] A total of 96 healthy adult Tan sheep ewes of similar age and body weight from the same sheep farm in Yanchi, Ningxia were selected for the experiment, divided into two treatments, and each treatment had 4 replicates. Each replicate has 12 Tan sheep. Treat 1 as comparative example 1 and feed mutton sheep fattening period concentrate supplementary material (provided by Xi'an Tieqi Lishi Feed Co., Ltd.) and sufficient roughage (alfalfa hay and wheat straw mixture), and deal with 2 is the Tan sheep that the present invention implements 1 is fed by test group Full price pellet feed. All experimental groups were housed without grazing and fed three times a day.

[0047] The pre-test was started 7 days before the formal test, and the formal test was started after the flock grouping and feed transition were completed during the pre-test, and the test was carried out fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com