Urease-driven tank-shaped micro-nano motor and preparation method thereof

A micro-nano, micro-nano particle technology, applied in microstructure devices, welding equipment, manufacturing tools and other directions composed of components that move relative to each other, can solve the problems of low movement rate and weak driving force, and achieve adjustable movement behavior. , the effect of strong driving force and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

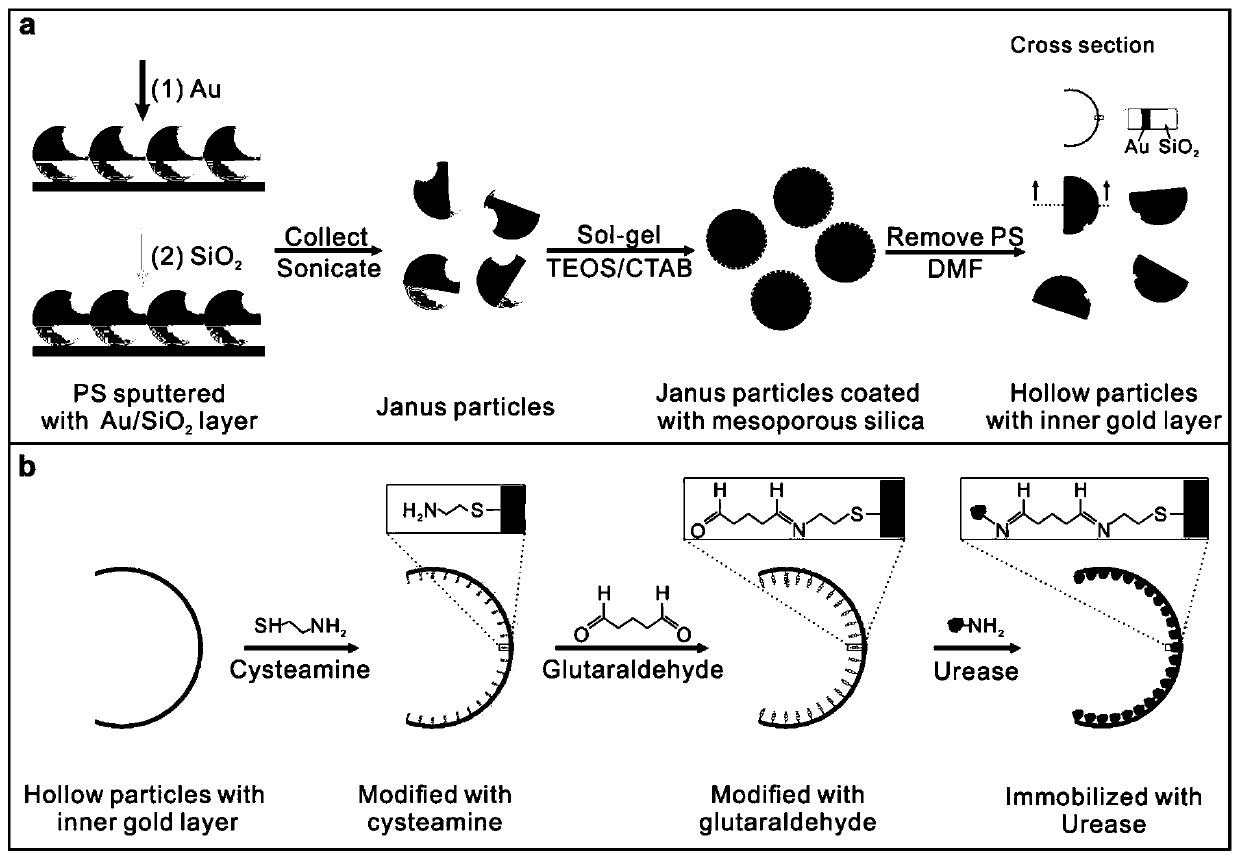

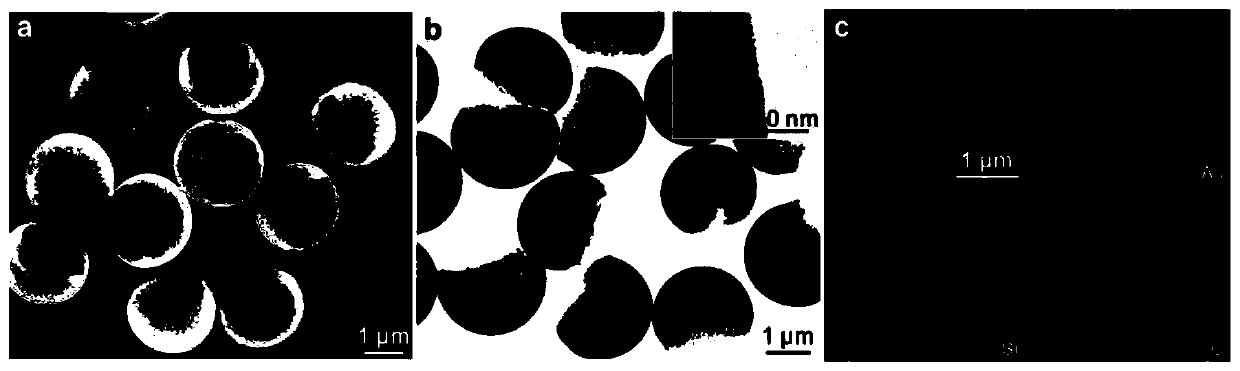

[0024] The preparation process of urease-driven pot-shaped micro-nanomotor is as follows: figure 1 As shown, it mainly includes two parts: (1) preparation of pot-shaped micro-nano particles, and (2) modification of urease on the inner surface of pot-shaped micro-nano particles.

[0025] (1) Preparation of jar-shaped micro-nanoparticles. First, after cleaning the glass slide, use oxygen plasma for hydrophilic treatment; then, drop 50 μL of PS microsphere ethanol suspension (2.3 μm, 10 mg / mL) onto the glass slide, and a single layer of PS microspheres can be formed after the ethanol evaporates. ball. Use the magnetron sputtering DC power supply to spray the gold layer for 50 seconds, and the RF power supply to spray the silicon dioxide for 40 seconds to obtain double-sided God particles. Disperse the prepared Shuangmianshen particles in 2mL deionized water, add 4mg TEOA, 7.4mg CTAB, 10μLTEOS in turn, react at 80°C for 2h, collect by centrifugation, wash with DMF 5 times, shake...

Embodiment 2

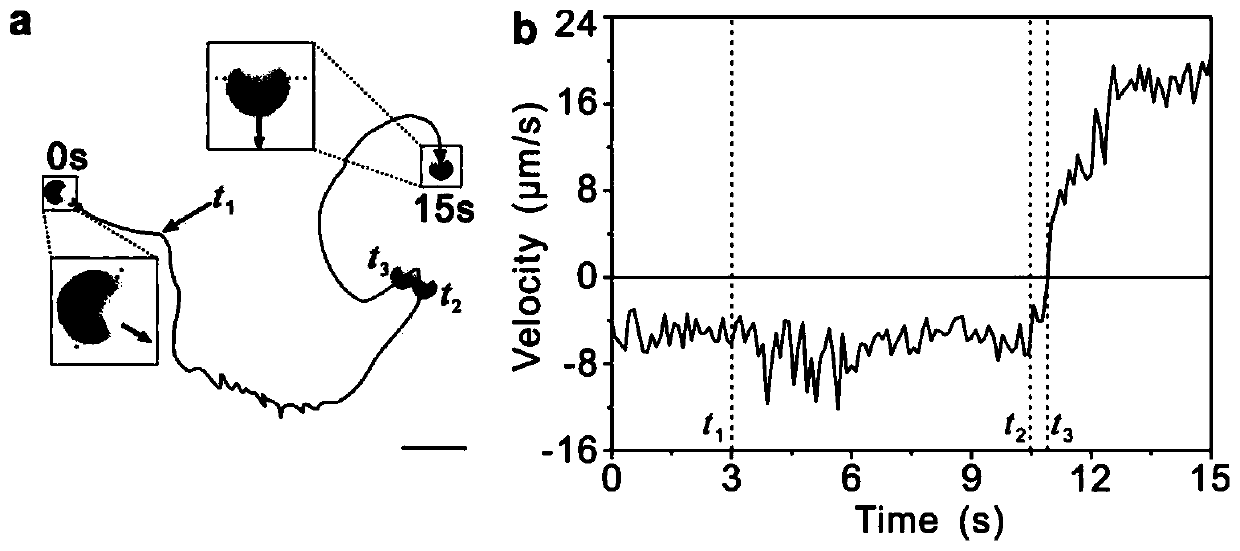

[0029] The urease-driven pot-shaped micro-nanomotor obtained in Example 1 was placed in 0.6 mM urea solution, and 50 mM urea solution was added after its movement became stable. Its trajectory is as image 3 As shown in a, before adding 50mM urea solution, urease drives the micro-nano motor to move towards the opening direction, and after adding 50mM urea solution, it moves back to the opening direction, and its real-time speed changes as follows image 3 As shown in b.

Embodiment 3

[0031] The urease-driven tank-shaped micro-nanomotor obtained in Example 1 was placed in a 5 mM urea solution, and deionized water was added after its motion became stable. Its trajectory is as Figure 4 As shown in a, before deionized water is added, urease drives the tank-shaped micro-nano motor to move away from the opening direction, and after adding deionized water, it moves towards the opening direction, and its real-time speed changes as follows Figure 4 As shown in b.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Opening size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com