Method for preparing granular active carbon by using biomass

A technology for granular activated carbon and biomass, which is applied in the fields of biofuels, separation methods, chemical instruments and methods, etc., can solve the problems of poor activation effect of granular activated carbon, high cost, large economic cost, etc., and achieve considerable economic prospects and ecological benefits. , enhance the compressive strength, reduce the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

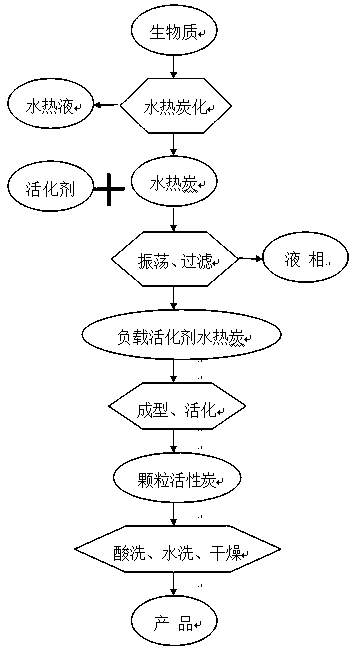

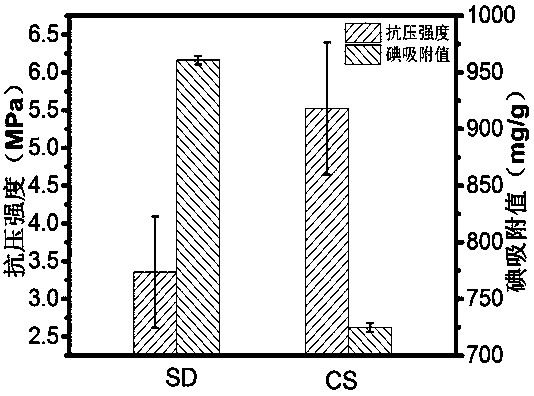

[0026] A method for preparing granular activated carbon from sawdust or corn stalks. Specific steps are as follows:

[0027] (1) Dry wood chips or corn stalks and crush them into wood chips or corn stalk powder;

[0028] (2) Add 150g of sawdust or corn stalk powder obtained in step (1) into the hydrothermal reaction kettle, and at the same time add 900mL of deionized water to obtain a mixture of sawdust or corn stalk;

[0029] (3) Heat the mixture of wood chips or corn stalks in step (2) to 180°C, keep the reaction for 0.5 hours, and the speed of mechanical stirring is 150 r / min;

[0030] (4) After the reaction, cool and filter to obtain solid-phase hydrothermal charcoal, and put the solid-phase hydrothermal charcoal in an oven to dry at 80°C;

[0031] (5) Weigh 10g of the dried solid-phase hydrothermal charcoal obtained in step (4), add activator (zinc chloride 20g, ferric chloride concentration 12.97g) and 100mL deionized water, soak for 24 hours, and then carry out Filte...

Embodiment 2

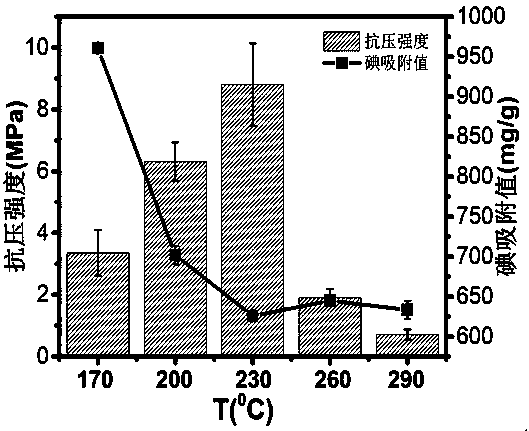

[0036] A method for preparing granular activated carbon from sawdust. Specific steps are as follows:

[0037] (1) Dry the sawdust and crush it into sawdust powder;

[0038] (2) Add 150g of sawdust powder obtained in step (1) into a hydrothermal reaction kettle, and add 900mL of deionized water at the same time to obtain a sawdust mixture;

[0039] (3) Heat the sawdust mixture in step (2) to 170°C, 200°C, 230°C, 260°C, and 290°C respectively, keep the reaction for 0.5 hours, and mechanically stir at a speed of 150 r / min;

[0040] (4) After the reaction, cool and filter to obtain solid-phase hydrothermal charcoal, and put the solid-phase hydrothermal charcoal in an oven to dry at 80°C;

[0041] (5) Weigh 10g of the dried solid-phase hydrothermal charcoal obtained in step (4), add activator (zinc chloride 20g, ferric chloride concentration 12.97g) and 100mL deionized water, soak for 24 hours, and then carry out Filter and dry in an oven at 80°C to obtain hydrothermal charcoal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com