Label ink capable of continuously resisting yellowing at a temperature of 300 DEG C and used for PI substrates

A technology of anti-yellowing and base material, which is applied in the field of ink, can solve the problems of poor high-temperature yellowing resistance and low ink adhesion, and achieve the effects of easy coating, less damage, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

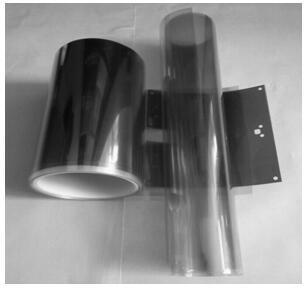

Image

Examples

Embodiment 1

[0028] In parts by weight, mix 35 parts of SK saturated polyester resin (ES365 molecular weight 40000, Tg point at 15-35°C), 20 parts of TOYOBO saturated polyester resin (270 molecular weight 23000, Tg point at 45-75°C) and 2 parts of fat family amide dispersant (Basf0451), 3 parts of dispersing solvent ethyl acetate, 2 parts of acrylic modified polyester modifying agent, 2 parts of dialkyl dithiophosphate zinc stabilizer, stir at low speed (700rpm*10min), and then Add 30 parts of pigment titanium dioxide (R-706) and 6 parts of 5000 mesh talc powder filler in turn, and disperse evenly at high speed (1500rpm*30min). Fully dispersed can make the pigment and filler form an effective wetting effect with the resin, making the system stable The stability performance is greatly improved, and the pigments and fillers are fully developed; then the dispersed materials are ground on a three-roller machine for 6 times, and ethyl acetate is added to a solid content of 70% (viscosity is 1000...

Embodiment 2

[0031] In parts by weight, 40 parts of BOSTIK saturated polyester resin (3350B molecular weight 70000, Tg point at 15-35°C), 30 parts of SK saturated polyester resin (ES120 molecular weight 28000, Tg point at 45-75°C) and 8 parts of poly Ester dispersant (Euca 605), 1 part of dispersing solvent ethyl acetate, 1 part of acrylic modified polyester modifier, 1 part of zinc dialkyldithiocarbamate, stir at low speed (600rpm*10min), and then Add 10 parts of pigment carbon black (MA-100) and 10 parts of filler 5000 mesh barium sulfate micropowder in sequence, and disperse evenly at high speed (1200rpm*30min). Full dispersion can make the pigment and filler form an effective wetting effect with the resin, making the system stable The stability performance is greatly improved, and the pigments and fillers are fully developed; then the dispersed materials are ground on a sand mill for 6 times, and then ethyl acetate is added to a solid content of 60% (viscosity is 8000CPS), and the dispe...

Embodiment 3

[0034] In parts by weight, mix 30 parts of SK saturated polyester resin (ES320 molecular weight 33000, Tg point at 15-35°C), 40 parts of BOSTIK saturated polyester resin (2250B molecular weight 35000, Tg point at 45-75°C) and 5 parts of fat family amides (Basf 0451), 3 parts of dispersing solvent methyl ethyl ketone, 3 parts of acrylic modified polyester modifier, 2 parts of stabilizer N-phenyl-α-naphthylamine, stir at low speed (600rpm*10min), and then Add 9 parts of color pigment (Basf 7079) and 8 parts of filler 3000 mesh calcium carbonate micropowder, and disperse evenly at high speed (1300rpm*30min). Fully dispersed can make the pigment and filler form an effective wetting effect, which greatly improves the stability of the system. Improve and fully develop the pigment and filler; then grind the dispersed material on a three-roll machine for 6 times, then add ethyl acetate to a solid content of 65% (viscosity is 9000CPS), and disperse evenly at a low speed (600rpm*10min) t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com