Preparation method of gallic acid and protocatechuic acid, and preparation method of reaction catalyst thereof

A technology of gallic acid and enzyme catalysts, applied in biochemical equipment and methods, oxidoreductases, enzymes, etc., can solve the problems of rising prices of plant-derived tannins and increased production costs of gallic acid, and achieve reduced production costs and simplified processes , the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1 Construction of prokaryotic expression system

[0042] The aroZ fragment of 3-dehydroshikimate dehydratase gene was synthesized by Nanjing GenScript Biotechnology Co., Ltd. and recombined into pET21a vector. The positive recombinant plasmid aroZ-pET21a(+) was transformed into the expression host strain BL21(DE3) (purchased from Tiangen Biochemical Technology (Beijing) Co., Ltd.), and the prokaryotic expression strain aroZ-pET21a(+) / BL21(DE3) was obtained as a follow-up Catalyzed reaction primary strains.

[0043] The p-hydroxybenzoic acid hydroxylase gene pobA fragment was synthesized by Nanjing GenScript Biotechnology Co., Ltd., and recombined into the pET21a vector. The positive recombinant plasmid pobA-pET21a(+) was transformed into the expression host strain BL21(DE3) (purchased from Tiangen Biochemical Technology (Beijing) Co., Ltd.), and the prokaryotic expression strain pobA-pET21a(+) / BL21(DE3) was obtained as a follow-up Catalyzed reaction primary st...

Embodiment 2

[0044] Embodiment 2 Fermentation preparation of enzyme

[0045] The expression strain constructed above aro Z -pET21a(+) / BL21(DE3), pobA-pET21a(+) / BL21(DE3) was added with a final concentration of 100ug / mL ampicillin in 5mL LB liquid medium [10g / L tryptone (OXIOD), 5g / L yeast powder (OXIOD), 10g / L chlorine Sodium chloride (Sinopharm Reagent)] was shaken at 37°C and 200rpm overnight, inoculated in 500mL LB liquid medium containing ampicillin with a final concentration of 100ug / mL at a ratio of 1% (V / V), and incubated at 37°C, 200rpm shaking culture. When the OD600 was between 0.8-1.0, the inducer IPTG (isopropyl-β-D-thiogalactopyranoside, IPTG) was added at a final concentration of 0.1 mM, and induced overnight at 25°C. The bacteria were collected by centrifugation at 8000rpm, then suspended in 50mM pH7.0 sodium phosphate buffer, ultrasonically disrupted (200W, 3s / 5s, 10min), centrifuged at 12000rpm at 4°C for 20min, and the supernatant was taken for use.

Embodiment 3

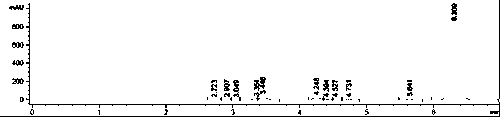

[0047] In 800ml of aqueous solution containing 50g of substrate I (3-dehydroshikimic acid), add phosphate to a final concentration of 50mM, and the pH value of the solution reaches 7.0. After stirring and dissolving, add 200mL of 3-dehydroshikimate dehydratase enzyme solution so that The final volume is 1 L. The reaction solution was placed in a constant temperature water bath at 37°C and mechanically stirred for reaction. After reacting for 1h, carry out HPLC detection, the conversion rate of substrate>98%, see figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com