Method for catalytic oxidation of fuel oil desulfurization with three-component deep eutectic solvent

A technology of deep eutectic solvent and catalytic oxidation, which is applied in the fields of refining oxygen-containing compounds, petroleum industry, and treating hydrocarbon oil, etc. It can solve the problems of volatility and corrosion, achieve high catalytic oxidation desulfurization performance and reactant utilization 100% efficiency and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

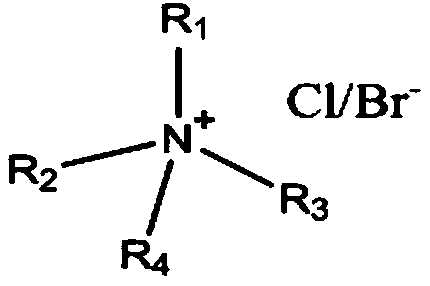

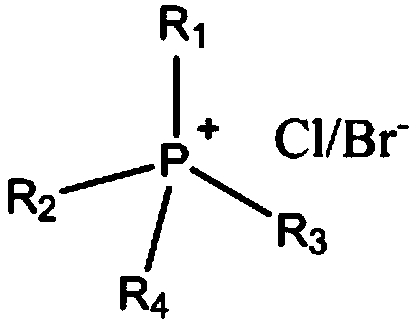

[0024] (1) Prepare deep eutectic solvent No. 1 (DES1) by tetramethylammonium chloride, boric acid, ethylene glycol with a molar ratio of 1:0.1:1;

[0025] (2) Dibenzothiophene (DBT) is dissolved in dodecane, and is made into the fuel oil that sulfur content is 500ppm; Add the DES1 of 0.1g in the fuel oil of 5g sulfur content 500ppm, add 10wt%H again 2 o 2 , H 2 o 2 The ratio to the amount of sulfide (DBT) in fuel oil is 2:1. At this time, the deep eutectic solvent phase is in the lower layer, and the oil phase is in the upper layer. H 2 o 2 Dissolved in a deep eutectic solvent; after magnetic stirring at 0°C for 30 minutes, the fuel oil was separated, and the content of DBT in the oil was detected by GC-FID, and the sulfur removal rate was calculated to be 31.3%;

[0026] (3) Recovery of the deep eutectic solvent: After the fuel oil is separated, add 1 times the volume of water to the remaining liquid containing the deep eutectic solvent and mix it. Since the deep eutectic...

Embodiment 2

[0028] (1) Prepare deep eutectic solvent No. 2 (DES2) by trioctylmethyl ammonium chloride, boric acid, polyethylene glycol 200 with a molar ratio of 1:1:0.1;

[0029] (2) Dissolve 4-methyldibenzothiophene (4-MDBT) in dodecane to make fuel oil with a sulfur content of 500ppm; add 1g to 5g of fuel oil (4-MDBT) with a sulfur content of 500ppm DES2, 20wt%H 2 o 2 , H 2 o 2 The ratio to the amount of sulfide (4-MDBT) in fuel oil is 4:1. At this time, the deep eutectic solvent phase is in the lower layer, and the oil phase is in the upper layer. H 2 o 2 Dissolved in a deep eutectic solvent; after magnetic stirring at 20°C for 60 minutes, the fuel oil was separated, and the content of 4-MDBT in the oil was detected by GC-FID, and the sulfur removal rate was calculated to be 52.5%;

[0030] (3) Recovery of the deep eutectic solvent: After the fuel oil is separated, add 2 times the volume of water to the remaining liquid containing the deep eutectic solvent to mix, because the deep...

Embodiment 3

[0032] (1) Prepare deep eutectic solvent No. 3 (DES3) by dodecyltrimethylammonium bromide, boric acid, glycerol with a molar ratio of 1:2:2;

[0033] (2) dibenzothiophene (DBT) is dissolved in dodecane, is made into the fuel oil that sulfur content is 500ppm; In the fuel oil (DBT) of 5g sulfur content 500ppm, add 5g DES3, 30wt%H 2 o 2 (H 2 o 2 The ratio of the amount of sulfide to fuel oil is 6:1), at this time, the deep eutectic solvent phase is in the lower layer, and the oil phase is in the upper layer, and H 2 o 2 Dissolved in a deep eutectic solvent; after magnetic stirring at 50°C for 8 hours, the fuel oil was separated, and the content of DBT in the oil was detected by GC-FID, and the sulfur removal rate was calculated to be 99.5%;

[0034] (3) Recovery of the deep eutectic solvent: After the fuel oil is separated, add 3 times the volume of water to the remaining liquid containing the deep eutectic solvent to mix, because the deep eutectic solvent is soluble in wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com