Organic photovoltaic material and preparation method and application thereof

A technology of organic photovoltaic materials and organic photovoltaic devices, which is applied in the fields of photovoltaic power generation, organic chemistry, semiconductor/solid-state device manufacturing, etc., can solve the problem of low spectral coverage in the near-infrared region, and achieve high photoelectric conversion efficiency, energy level and easy spectrum Adjust and prepare simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation of IDDT-DTM: 4,4,9,9-tetrakis(4-hexylphenyl)-4,9-dihydro-s-indacene[1,2-b:5,6-b']di Thiophene-2,7-dicarbaldehyde (107.4 mg, 0.1 mmol) and DTM (44 mg, 0.22 mmol) were dissolved in 10 mL of chloroform, then 0.1 mL of piperidine was added. The solution was stirred at 80°C for 8 hours. The mixture was then diluted with chloroform and washed three times with brine. The organic phases were combined and washed with MgSO 4 dry. After removing the solvent, the resulting residue was purified by column chromatography using hexane as eluent to give IDDT-DTM (36.8 mg, 30.1%) as a dark blue solid.

[0029] Implementation route:

[0030]

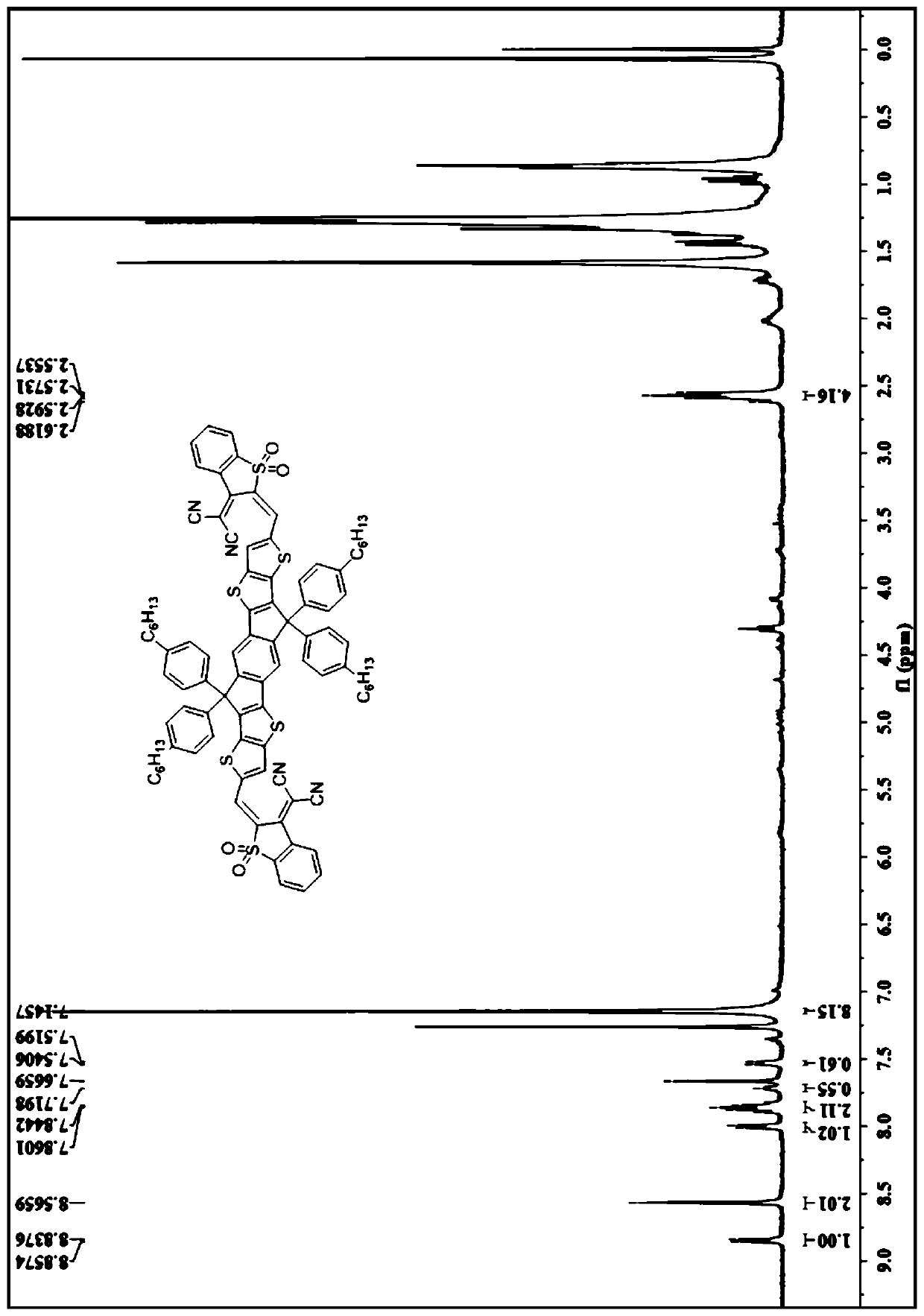

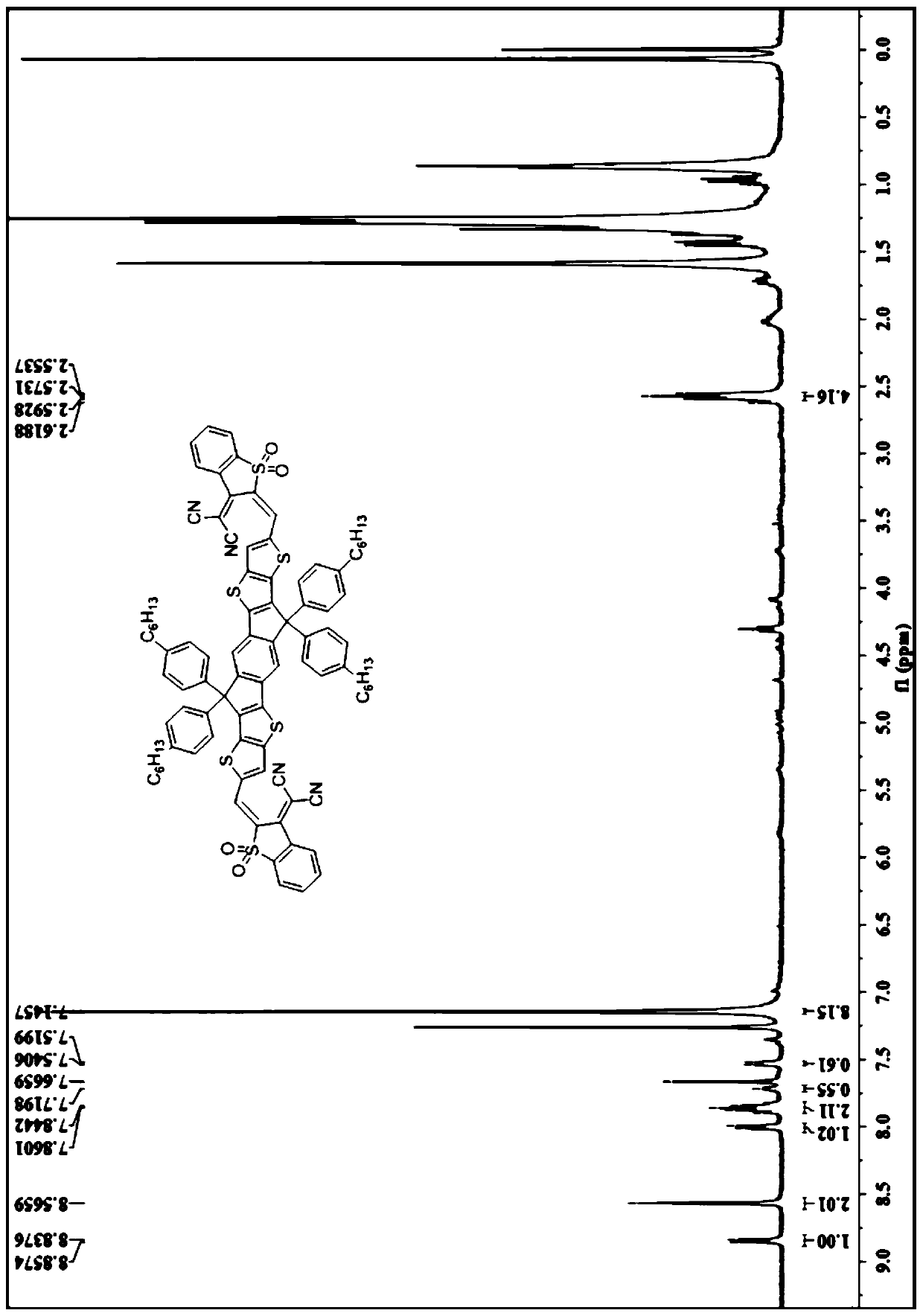

[0031] 1 H NMR (400MHz, CDCl 3 )δ8.85(d, J=7.9Hz, 2H), 8.57(s, 2H), 8.00(d, J=6.6Hz, 1H), 7.87(dd, J=13.8, 7.1Hz, 2H), 7.72( s,1H),7.53(d,J=8.3Hz,1H),7.15(s,8H),2.60–2.54(m,4H).MALDI-TOF-MS(m / z): Calcd for C 92 h 82 N 4 o 4 S 6 ,Exact Mass:M + 1498.47; Found: 1498.356 (M + ).

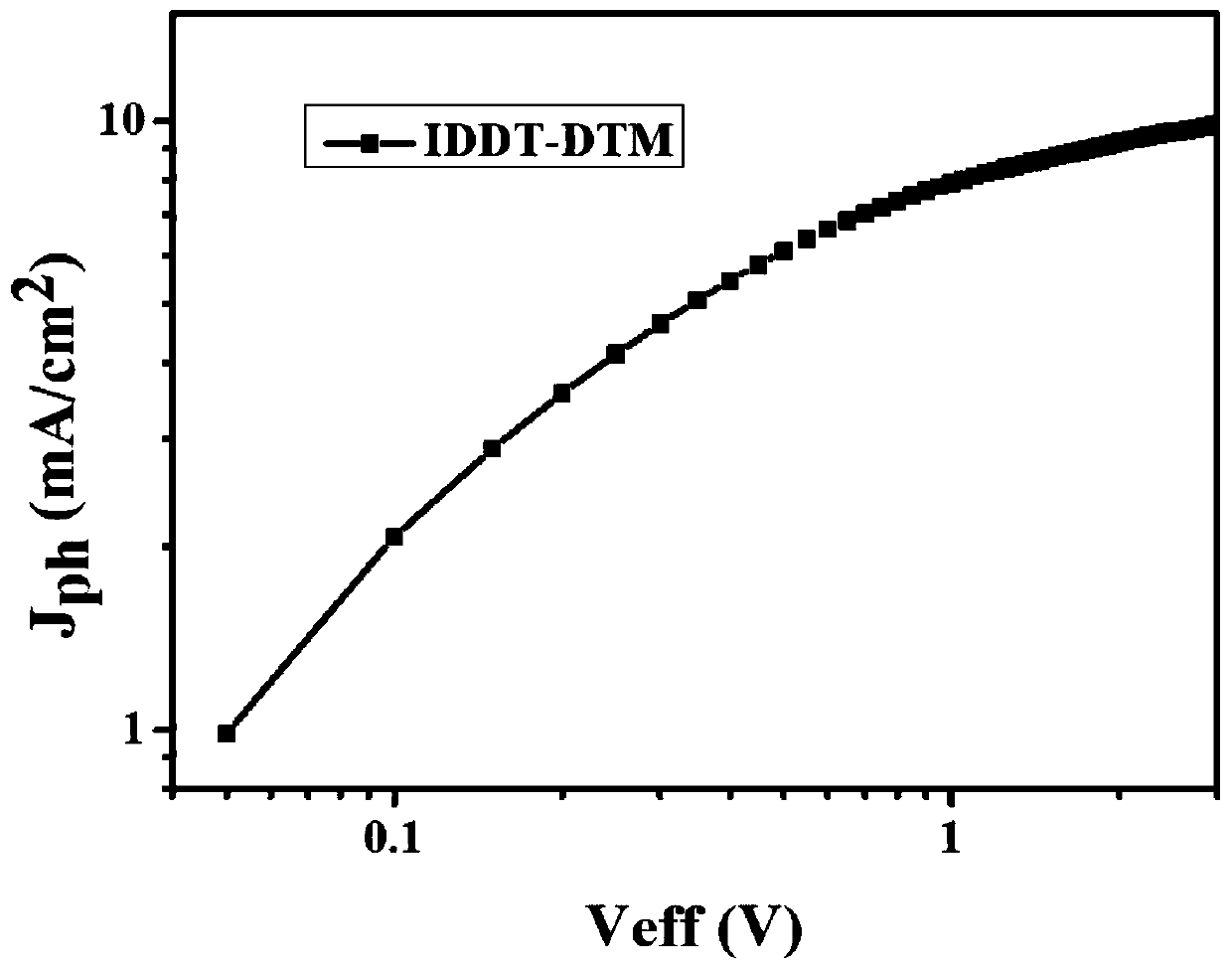

[0032] Device preparation: first patterned...

Embodiment 2

[0034] The preparation process of IDT-C8: 4,4,9,9-tetrakis(4-hexylphenyl)-4,9-dihydro-s-benzobisindeno[1,2-B:5,6- B']dithiophene-2,7-dicarbaldehyde (96.25mg, 0.1mmol) and DTM (44mg, 0.22mmol) were placed in a two-necked reaction flask, and after adding 10mL of ethanol, slowly heated to 80°C until all the reactants were dissolved. After adding 0.1mL of triethylamine to ethanol, the solution turns red-blue. After the reaction, the product precipitates out of ethanol. After filtration, it is purified by column chromatography using hexane as the eluent to obtain IDT-C8 as a dark blue solid. (33.4 mg, 37%).

[0035] Implementation route:

[0036]

[0037] 1 H NMR (400MHz, CDCl 3 )δ8.89(d, J=7.6Hz, 2H), 8.03(d, J=6.6Hz, 1H), 7.92–7.85(m, 2H), 7.80(s, 1H), 7.57(s, 2H).

[0038] Device preparation: first patterned ITO (sheet resistance=15Ωsq -1 ) glass substrates were pre-cleaned by sequential ultrasonication in detergent, deionized water, acetone, and isopropanol. And the su...

Embodiment 3

[0040] The preparation process of FTBr-TBA: the precursor 5,5'-(9,9-bis(6-bromohexyl)-9H-fluorene-2,7-diyl)bis(thiophene-2-carbaldehyde) (71.5mg ,0.1mmol) and TBA (44mg, 0.22mmol) were placed in a two-necked reaction flask, and after adding 10mL of ethanol, slowly heated to 80 degrees Celsius. Since the precursor had an alkyl chain bromide and had a high structural activity, there was no need to add it later Catalyzed by any base, the solution slowly turned blue-purple after 8 hours of reaction. After the reaction was completed, the column chromatography using hexane as eluent was purified to obtain FTC8-DTM as a dark blue solid.

[0041] Implementation route:

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com