Iron oxide photo-anode system with embedded silicon pn junction and fabrication method of iron oxide photo-anode system

An iron oxide light and pn junction technology, applied in photovoltaic power generation, semiconductor devices, final product manufacturing, etc., can solve the problems of small photogenerated voltage, mismatch, carrier recombination, etc., and achieve the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

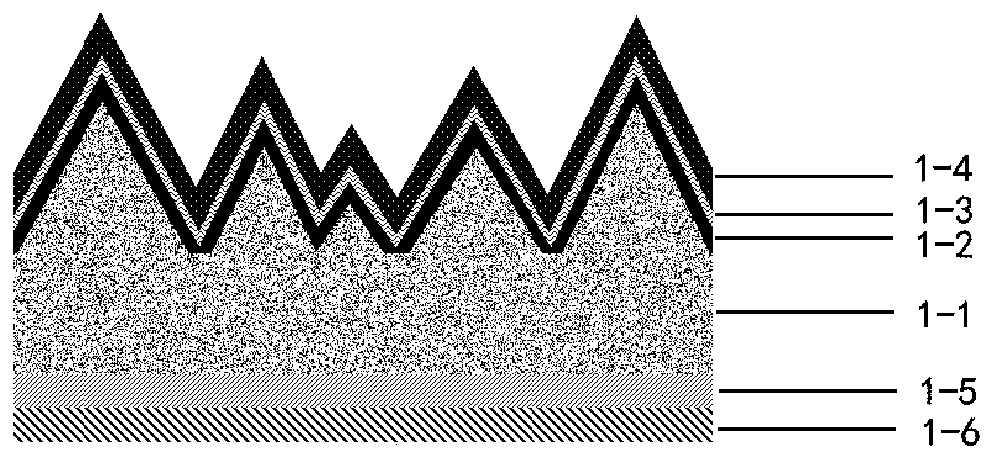

[0037] An iron oxide photoanode system with embedded silicon pn junction, such as figure 1 As shown: the photoanode is a composite layer structure, which sequentially includes an iron oxide absorption layer 1-4, a p-type silicon doped layer 1-2, an n-type silicon substrate 1-1, and a back conductive layer 1 along the light incident direction -5, the back waterproof insulation layer 1-6; the p-type silicon doped layer and the n-type silicon substrate form a silicon pn junction: (1) the morphology of the silicon pn junction is a pyramidal array structure; (2) p-type silicon A transparent conductive tunneling layer 1-3 is disposed between the doped layer 1-2 and the iron oxide absorbing layer 1-4, and the thickness of the transparent conductive tunneling layer is equal everywhere.

[0038] The iron oxide photoanode system with embedded silicon pn junction proposed by the present invention can completely photolyze water. The incident light enters the inside of the photoanode, and...

Embodiment 2

[0040] A method for preparing an iron oxide photoanode system embedded with a silicon pn junction, comprising the following steps:

[0041] 1) Use an n-type silicon wafer with a resistivity of 1-5 Ω·cm to perform standard RCA cleaning.

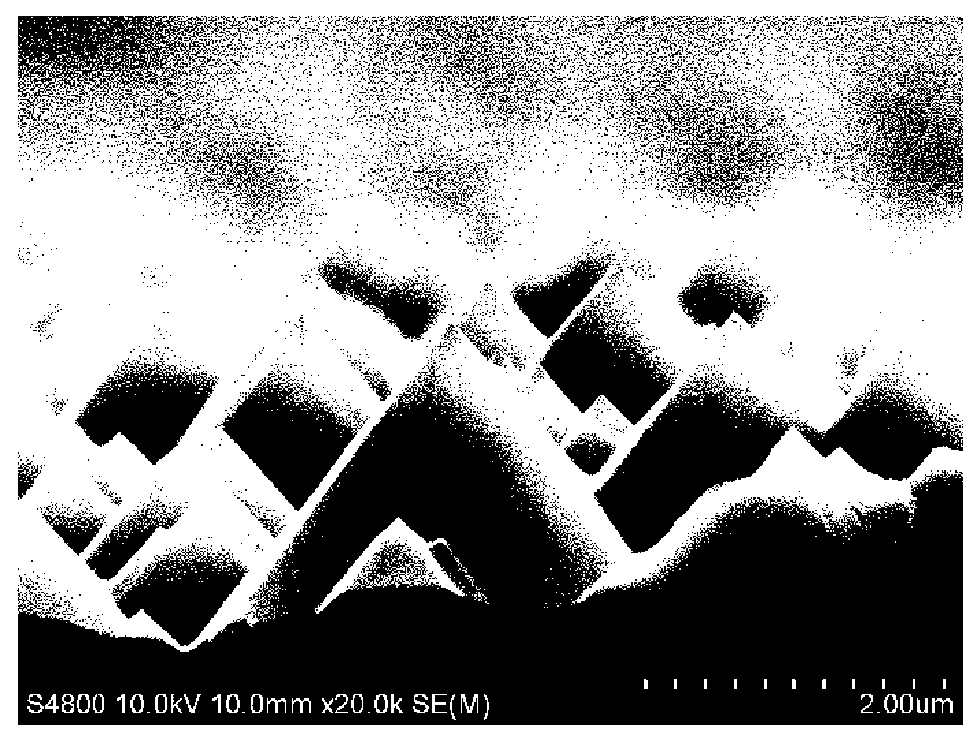

[0042] 2) In a mixed solution of potassium hydroxide and isopropanol, react at 80°C for 60 minutes, and clean the silicon wafer to obtain an n-type silicon pyramid array structure, such as figure 2 shown.

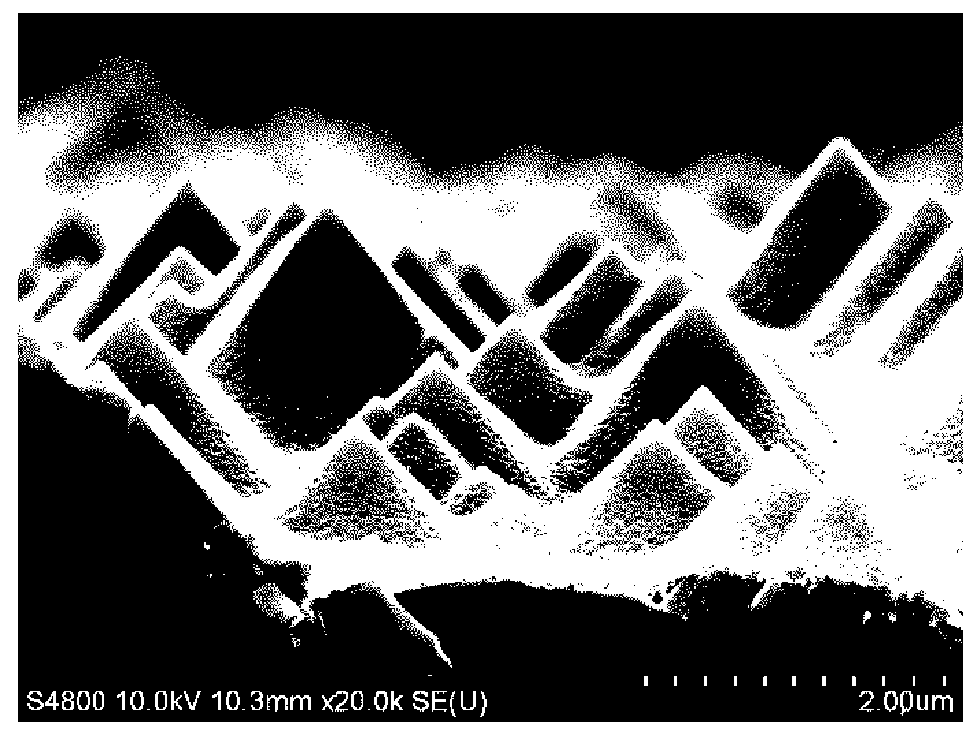

[0043] 3) The n-type silicon pyramid array obtained in step 2) is doped with boron by means of thermal diffusion, and the doping concentration is 2.0×10 19 cm -3 , the junction depth is 200nm. Protect the back side of the n-silicon during thermal diffusion, so that boron doping only occurs on the front side of the silicon pyramid structure.

[0044] 4) Put the prepared silicon pn junction pyramid array into the cavity of the atomic layer deposition system, using tetrakis(dimethylamino)tin as the tin source and tert-butyliminotris(dieth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com