Porous carbon, nano silicon and carbon core shell structure material and preparation method thereof

A technology of porous carbon materials and structural materials, applied in the field of electrochemistry, can solve problems such as complex processes and poor stability, and achieve the effects of improving Coulombic efficiency, low production costs, and improving the stability of material structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] In a preferred embodiment, the preparation method of the present invention comprises the following steps:

[0033] (1) Material etching: Mix the base carbon material and the activator at a mass ratio of 1:4-1:8 in a solvent at room temperature, dry at 60-90°C for 8-24 hours, and then vacuum filter to obtain the mixture. This step is mainly the pre-corrosion of graphite by alkali, and defects will be formed on the surface of carbon materials at this stage. From the perspective of the activation mechanism, the high-temperature etching of alkali is carried out at the defect, and it is difficult to etch holes in carbon materials lacking defects and micropores. There are obvious holes.

[0034] The mixture is heated to 200-300° C. for medium-temperature etching for 0.5-3 hours under an inert gas atmosphere, and then heated to 700-900° C. for high-temperature activation for 2-6 hours. The product was washed with water until neutral, filtered and dried to obtain a porous car...

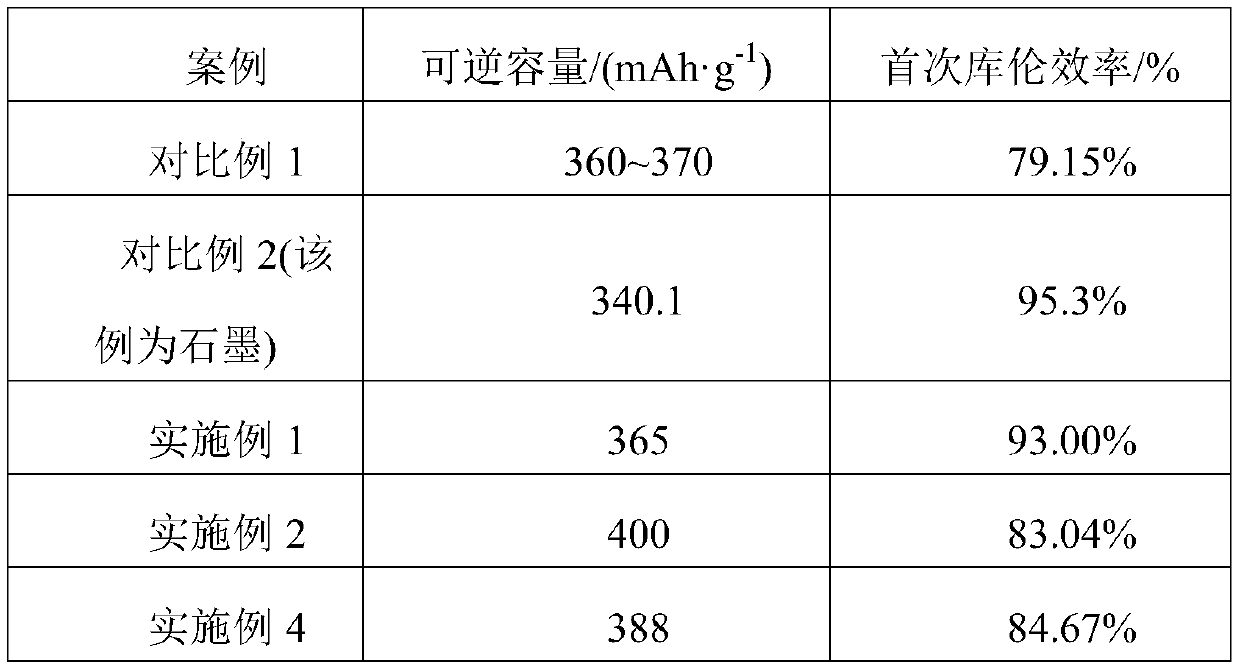

Embodiment 1

[0045] Take 24.00g graphite (reversible capacity 330mAh·g -1 ), 78.4gKOH was added to 300.00g deionized water, magnetically stirred at room temperature for 30min, then vacuum-dried at 80°C for 8h, then vacuum-filtered, the filtered mixture was placed in a tube furnace, and activated at 200°C for 1h under nitrogen protection. Then the temperature was raised to 900° C. for 2 hours of activation, and the product was washed with water to neutrality and filtered and dried to obtain a porous carbon material. Take 12.00g of porous carbon material, 1.5g of nano-silicon, add 8.5g of ethanol, ball mill at a speed of 200r / min for 2h, and dry the slurry in an oil bath at 85°C for 3h, and grind and pulverize the obtained silicon graphite sample. Take 8.00g of silicon graphite and 24.00g of 5% polyvinylpyrrolidone ethanol solution, mix evenly, and spray to granulate. Then the mixture was placed in a tube furnace, protected by argon, heated at 3°C / min to 900°C for 2h, and cooled naturally t...

Embodiment 2

[0047] Take 24.00g artificial graphite (reversible capacity 330mAh·g -1 ), 168.00gKOH, added 300.00g deionized water, magnetically stirred at room temperature for 30min, then air-dried at 80°C for 16h, then vacuum filtered, the filtered mixture was placed in a tube furnace, and activated at 250°C for 1h under nitrogen protection , activated at 800°C for 2h, the product was washed with water until neutral, filtered and dried in vacuum to obtain a porous carbon material. Take 36.00 g of porous carbon material, 4.5 g of nano-silicon, add 25.5 g of isopropanol, and ball mill at a speed of 200 r / min for 3 h. The obtained slurry is dried in an oil bath at 85° C. for 1 h, and the obtained silicon graphite sample is ground and pulverized. Take 8.00g of silicon graphite and 4.70g of asphalt heavy oil and mix evenly, put the mixture in a tube furnace, protect it with nitrogen, raise the temperature at 3°C / min to 900°C for 4h, cool naturally to room temperature, and obtain a composite ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inverse capacity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com