Phosphoric-acid-doped cross-linked polybenzimidazole high-temperature proton exchange membrane and preparation method thereof

A technology of polybenzimidazole and proton exchange membrane, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, fuel cells, etc. It can solve the problems of low viscosity, solubility, difficulty in controlling the degree of cross-linking, and few types of cross-linking agents. , to achieve the effects of improved mechanical strength and dimensional stability, easy large-scale preparation, and great application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Add 5.1646g (0.02mol) of 4,4'-diphenyl ether dicarboxylic acid and 4.2854g (0.02mol) of 3,3'-diaminobenzidine (DAB) into a 100mL three-necked flask. Add 30mL PPMA to the system (PPMA is a mixed solution of phosphorus pentoxide and methanesulfonic acid, its mass ratio is 1:10). in N 2 Under the atmosphere, start stirring and raise the temperature of the reaction system to 140° C., and keep at this temperature for 2 hours, so that the tetraamine and diacid monomers are completely dissolved in PPMA. Then the system was heated to 180°C and kept for 5h.

[0033] 2) When the viscosity of the system becomes viscous, the high-viscosity reaction product is slowly poured into a large amount of deionized water in a filament form under stirring, and the obtained product is washed several times, and then the polymer is pulverized into a powder with a high-speed pulverizer. With 10% NaHCO 3 The solution was washed at 40° C. for 48 h to obtain a powdery polymer. The powdered po...

Embodiment 2

[0035] 1) Add 0.1407g (1.4mol) of CuCl and 0.4353g (2.8mol) of 2,2'-bipyridine (bipy) into a long-necked reaction flask, then add 5mL of chlorobenzene and 2mL (2.166g, 14mol) of 4-Chloromethylstyrene (VBC). Freeze the solution in the flask into a solid with liquid nitrogen, vacuumize, fill with nitrogen, and thaw. This process is repeated three times to completely remove the residual oxygen in the system, and then seal it with a flame under vacuum. The reaction vessel was placed in an oil bath at 115° C. for 6 h.

[0036] 2) Add THF and stir at room temperature for 5 hours to dissolve the polymer and oxidize the catalyst. The resulting solution was filtered through an alumina column to remove insoluble copper salts and 2,2'-bipyridyl. The resulting light yellow solution was collected and precipitated in methanol to give a white precipitate. The crude product was redissolved in 30 mL THF and precipitated in methanol. The purification process was repeated three times, and th...

Embodiment 3

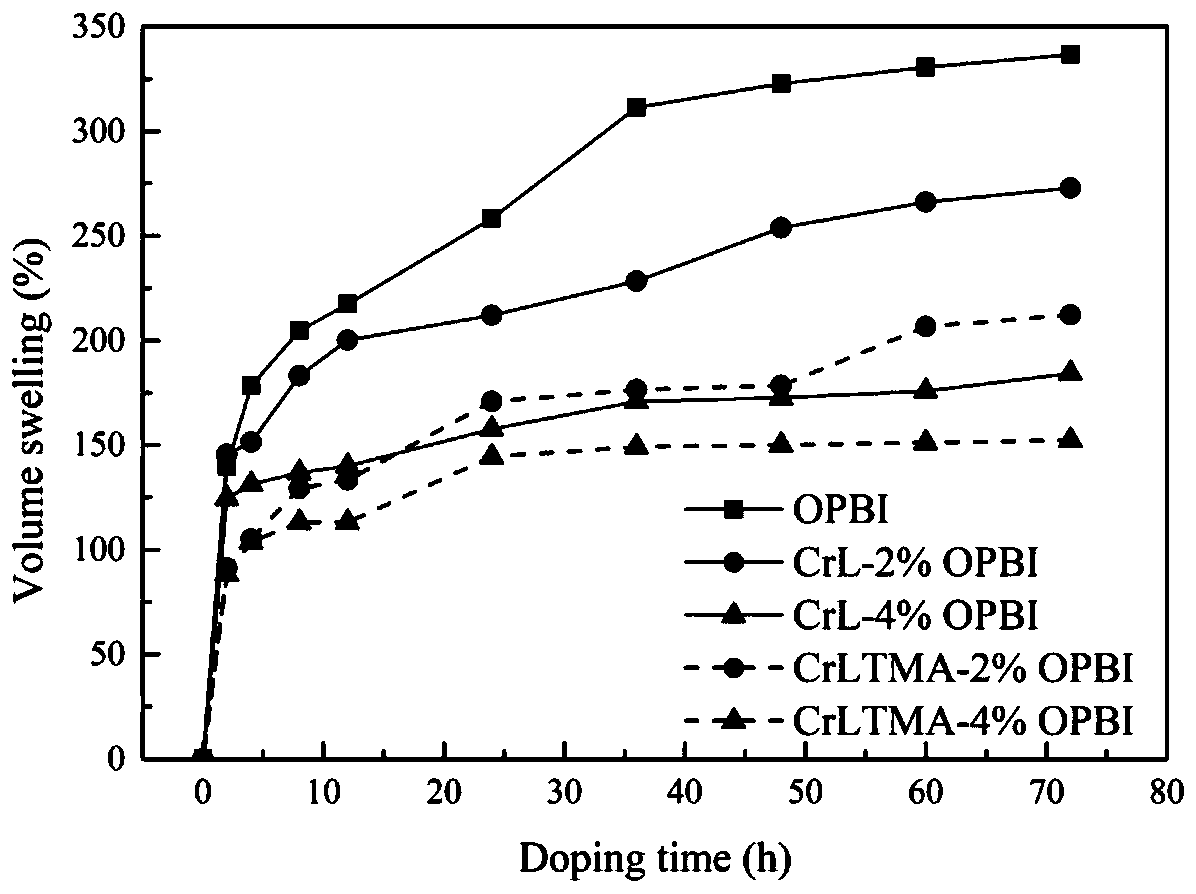

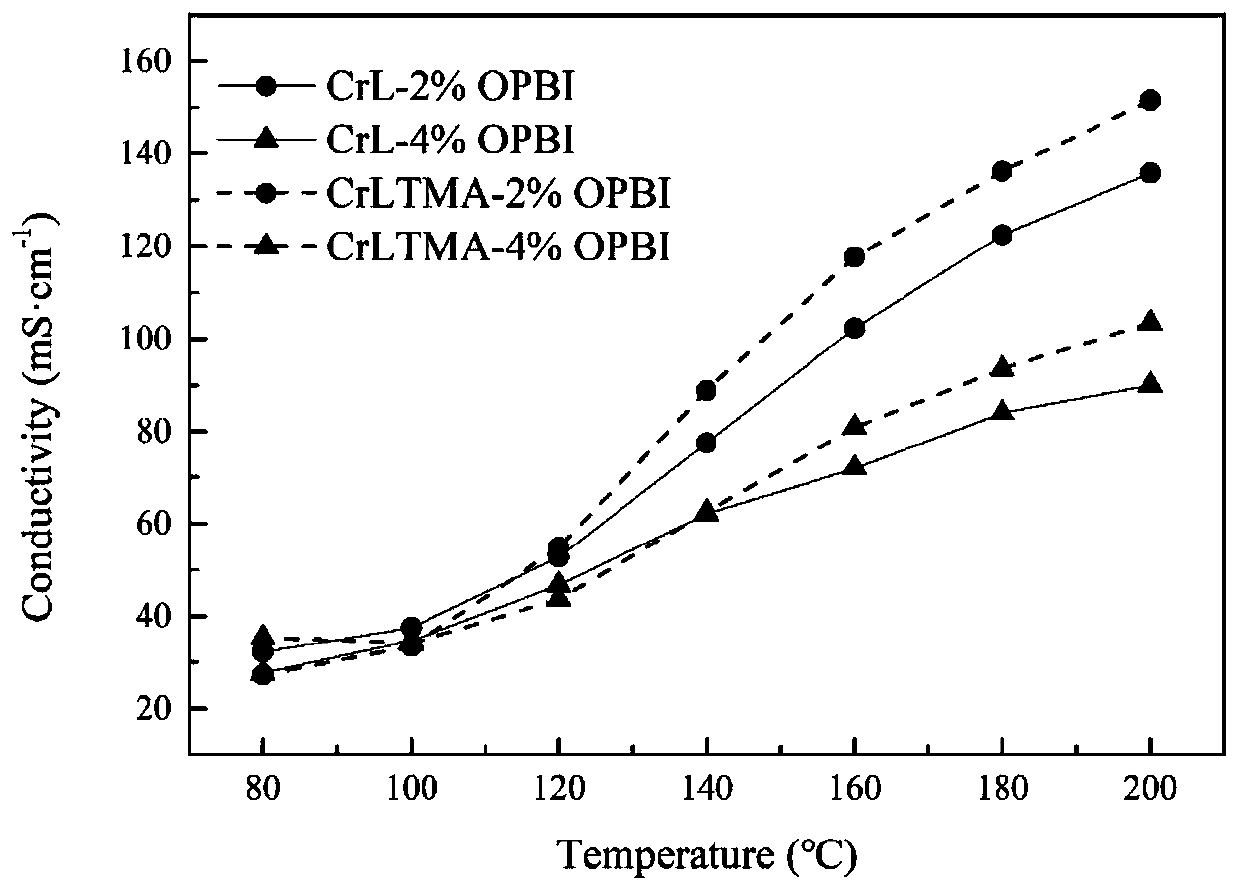

[0038] 1) OPBI with a quality of 3g (the molar number of polymer imidazole group is 1.5mmol) and hyperbranched poly-p-chloromethyl with a quality of 0.0910g (the molar number of chlorine in the repeating unit of the hyperbranched polymer is 0.03mmol) Styrene was dissolved in 80 mL and 5 mL of DMAc solvent, respectively. When the two polymers are completely dissolved, mix the two polymer solutions and stir at a high speed of 10,000 rpm for 30 minutes to make the two polymers evenly dispersed and fully mixed. Use a 400-mesh filter cloth to filter out impurities, cast on a clean glass plate, dry in a vacuum oven at 60°C for 12 hours, at 80°C for 12 hours, at 100°C for 12 hours, and finally vacuumize and keep at 120°C for 12 hours to obtain a cross-linked type Polybenzimidazole film (CrL-2% OPBI, wherein the molar ratio of chlorine atoms to OPBI imidazole groups in the repeating unit of poly-p-chloromethylstyrene is 2:100).

[0039] 2) Soak the obtained polybenzimidazole film in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com