Low melt viscosity, thermosetting polyimide precursor suitable for rtm molding and preparation method

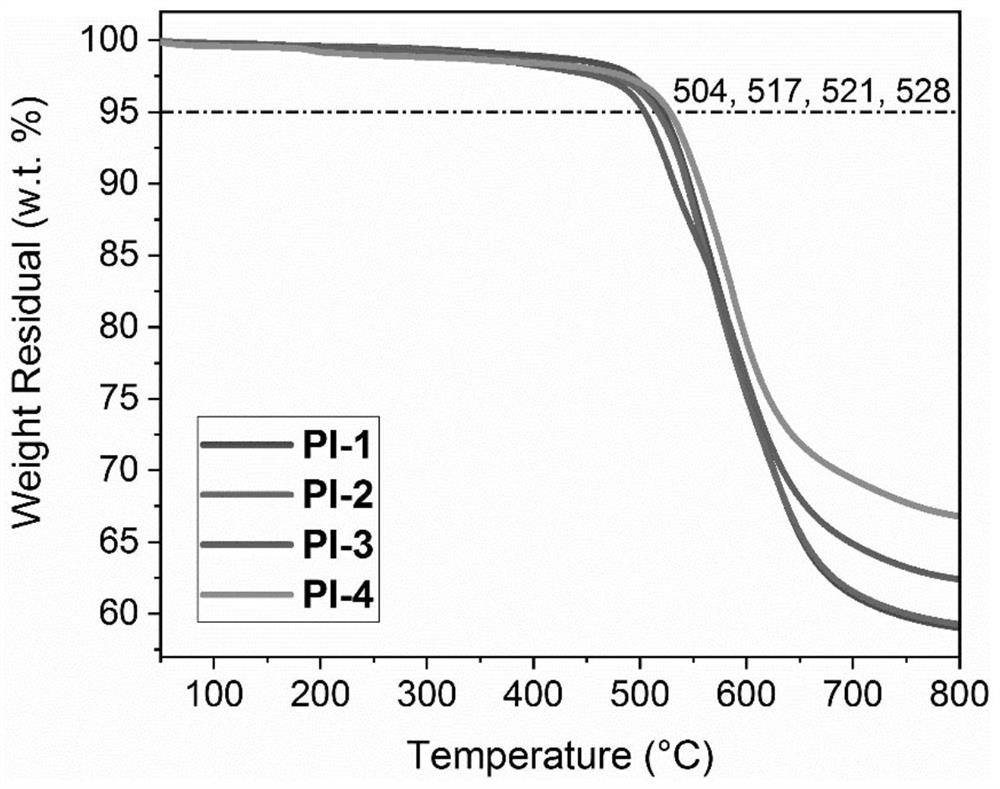

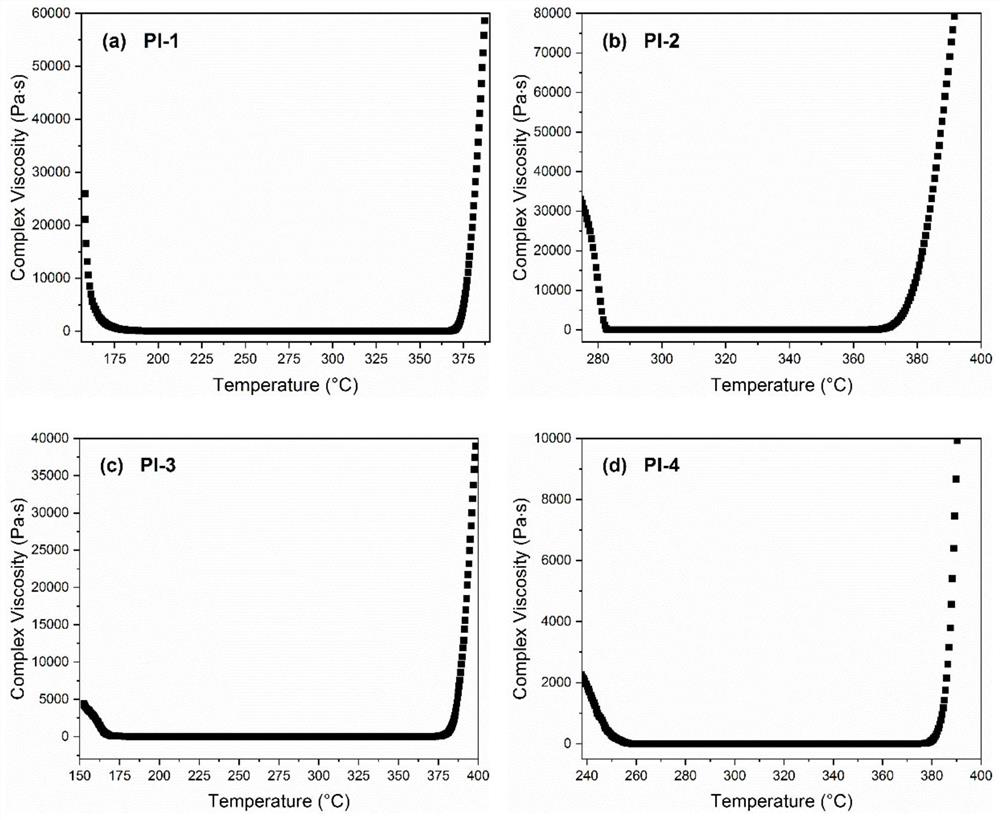

A polyimide precursor and melt viscosity technology, applied in organic chemistry and other fields, can solve the problems of narrowing temperature processing window, unfavorable RTM molding, narrow processing window, etc., and achieve the effect of outstanding thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

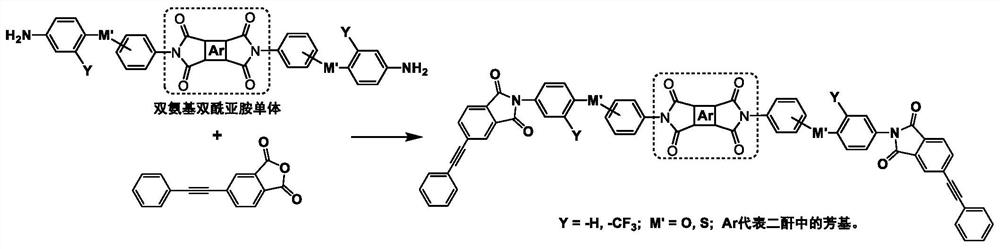

Method used

Image

Examples

preparation example Construction

[0054] A. Preparation of Nitro-Substituted Monoamino Compounds

[0055] The present invention prepares the nitro-substituted monoamino compound through the nucleophilic reaction between the phenolic compound and the halogenated nitrobenzene, and the specific reaction scheme is as follows:

[0056]

[0057] B. Preparation of Bisnitrobisimide Monomers

[0058] The present invention reacts the nitro-substituted monoamino compound and dibasic acid anhydride in a carboxylic acid solution, and adopts cyclohexane to azeotrope with water to obtain a bisnitrobisimide monomer, and the specific reaction scheme is as follows:

[0059]

[0060] C. Preparation of Bisaminobisimide Monomers

[0061] The present invention adopts the reduction technology of palladium-carbon catalytic hydrogenation to reduce the bisnitrobisimide monomer to obtain the bisaminobisimide monomer, and the specific reaction scheme is as follows:

[0062]

[0063] D. Preparation of Thermosetting Polyimide Pr...

Embodiment 1

[0066] 12.72 g of sodium carbonate, 16.37 g of p-aminophenol, 98 g of N,N-dimethylformamide, 15.75 g of o-nitrochlorobenzene and 1.5 mL of triphenyl phosphite were sequentially added to the reactor equipped with mechanical stirring. Under argon, stirring was started and the system was warmed. When the temperature rose to 90°C, the stirring was continued for 16h. When the system was cooled to 25°C, the reaction system was poured into deionized water, and a brown precipitate was precipitated. After suction filtration, the filter cake was washed three times with deionized water to obtain a crude product. The crude product was recrystallized, and the filter cake was collected after filtration and dried in a vacuum oven at 80° C. for 24 h to obtain 30.60 g of product E with a yield of 88.6%. 22.21g of 6FDA was added to a three-necked flask equipped with a water separator and a condensing reflux device at one time, 725g of acetic acid was added under argon atmosphere and mechanica...

Embodiment 2

[0068] In the reactor equipped with mechanical stirring, 16.59g potassium carbonate, 18.47g 2-methyl-3-aminophenol, 103g N,N-dimethylacetamide, 15.75g p-nitrochlorobenzene and 1.6mL trimethylacetamide were added successively. Phenyl phosphite. Under argon, stirring was started and the system was warmed. When the temperature rose to 100°C, the stirring was continued for 18h. When the system was cooled to 25°C, the reaction system was poured into deionized water, and a brown precipitate was precipitated. After suction filtration, the filter cake was washed twice with deionized water to obtain a crude product. The crude product was recrystallized, and the filter cake was collected after filtration and dried in a vacuum oven at 80° C. for 24 h to obtain 33.04 g of product E with a yield of 90.2%. 11.21g of a-BPDA was added to the three-necked flask equipped with a water separator and a condensing reflux device at one time, 700g of acetic acid was added under argon atmosphere an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com