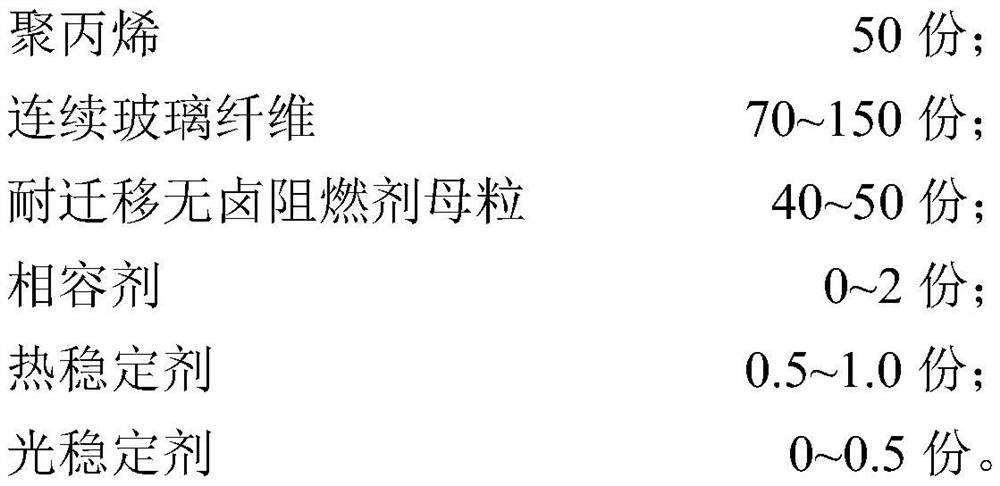

Flame-retardant continuous glass fiber reinforced polypropylene prepreg material and preparation method thereof

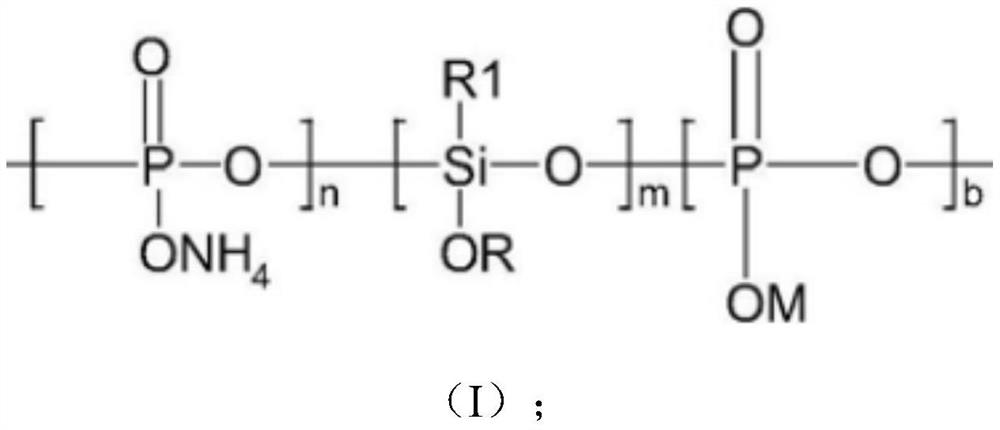

A glass fiber and polypropylene technology, which is applied in the field of polymer material processing, can solve the problems of composite material penetration, migration, hidden dangers of production stability, and reduced flame retardancy, so as to improve mechanical properties, solve migration and precipitation resistance, and ensure stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

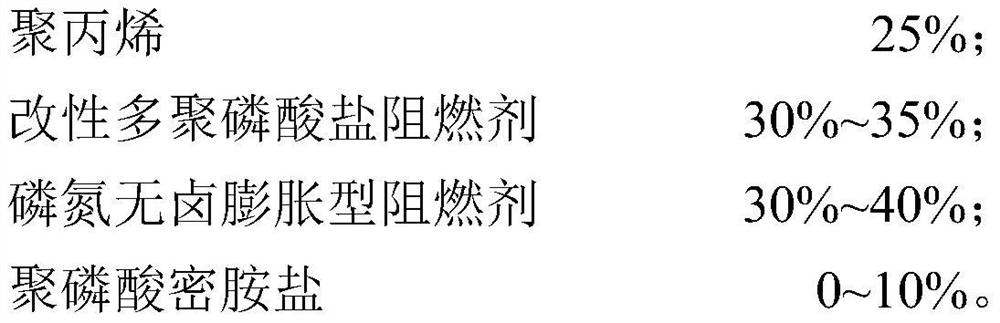

[0052] Add 10 parts of PP (the optional brand is SK BX3920), 12 parts of modified polyphosphate flame retardant, and 2 parts of polyphosphate melamine salt into the high-speed mixer in proportion to mix evenly, and enter the twin-screw extruder through the main feed In the discharge machine, 16 parts of phosphorus nitrogen halogen-free intumescent flame retardants are added in the fifth section of the screw barrel through side feeding, so that the flame retardants can be evenly dispersed and covered with polypropylene, and extruded and granulated to obtain The effective flame retardant is 75% high-content migration-resistant halogen-free flame retardant masterbatch.

[0053] Mix the prepared migration-resistant halogen-free flame retardant masterbatch with 50 parts of PP (the optional brand is SKHX3900), 1.0 parts of maleic anhydride grafted polypropylene (PP-g-MAH), 0.3 parts of antioxidant 1010, 0.2 parts Antioxidant 168, 0.1 part of light stabilizer HALS-944, 0.1 part of ul...

Embodiment 2

[0057] Add 12 parts of PP (the optional brand is K7100), 13 parts of modified polyphosphate flame retardant, and 4 parts of polyphosphate melamine salt into a high-speed mixer in proportion to mix evenly, and enter the twin-screw extrusion through the main feed In the machine, 16 parts of phosphorus-nitrogen halogen-free intumescent flame retardants are fed into the fifth section of the screw barrel through side feeding, so that the flame retardants can be evenly dispersed and covered by polypropylene, and extrusion granulation can obtain effective The flame retardant is 75% high-content migration-resistant halogen-free flame retardant masterbatch.

[0058] Mix the prepared migration-resistant halogen-free flame retardant masterbatch with 50 parts of PP (optional grade K7760), 2.0 parts of methacrylic acid grafted polypropylene (PP-g-MAA), 0.3 parts of antioxidant 1010, 0.3 parts Antioxidant PS802, 0.2 parts of light stabilizer HALS-944, 0.1 parts of ultraviolet absorber UV-77...

Embodiment 3

[0062] Add 12.5 parts of PP (the optional brand is K7100), 15 parts of modified polyphosphate flame retardant, and 5 parts of polyphosphate melamine salt into a high-speed mixer in proportion to mix evenly, and enter the twin-screw extrusion through the main feed In the machine, 17.5 parts of phosphorus, nitrogen, halogen-free intumescent flame retardants are fed into the fifth section of the screw barrel through side feeding, so that each flame retardant can be evenly dispersed and covered with polypropylene, and extrusion granulation can obtain effective The flame retardant is 75% high-content migration-resistant halogen-free flame retardant masterbatch.

[0063] Mix the prepared migration-resistant halogen-free flame retardant masterbatch with 50 parts of PP (optional grade K8065), 2.0 parts of methyl methacrylate grafted polypropylene (PP-g-MMA), 0.2 parts of antioxidant 1010, 0.1 part of antioxidant 168, 0.2 part of antioxidant DSTP, and 0.3 part of light stabilizer HALS-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com