A kind of artificial bone for repairing tumor bone defect and preparation method thereof

A technology for artificial bone and bone defect, applied in medical science, prosthesis, tissue regeneration, etc., to achieve excellent bone repair performance, solve the effect of local residual tumor cell recurrence, and excellent biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

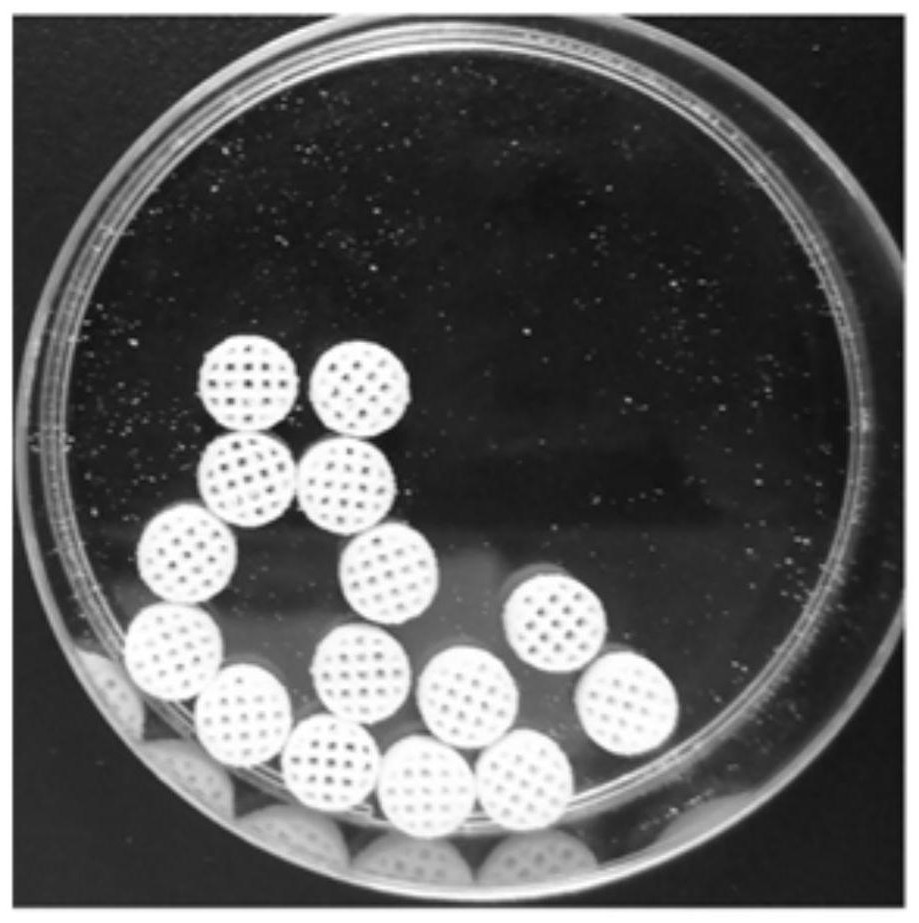

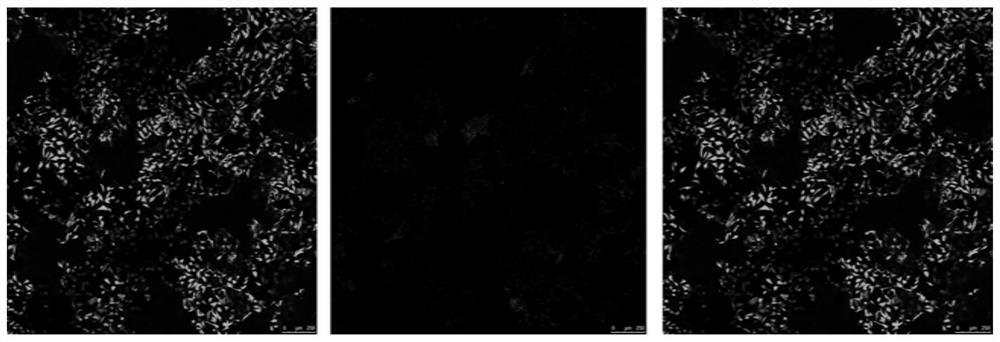

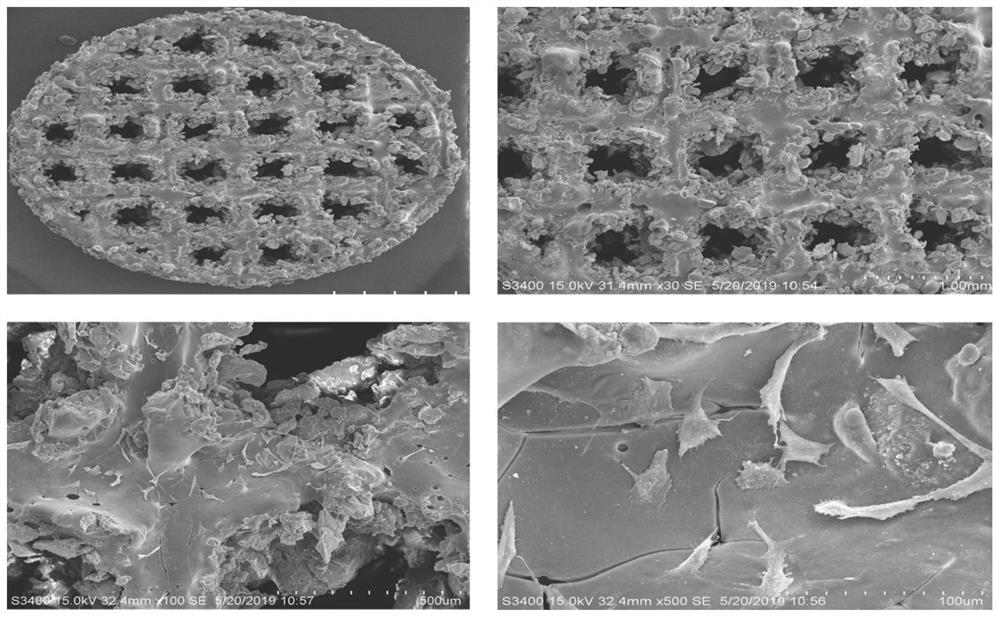

Image

Examples

Embodiment 1

[0031] 1. Composite powder preparation

[0032] (1) Mixing: Weigh PLLA and nHA at a ratio of 9:1, physically mix them, place them in a beaker filled with absolute ethanol, and disperse the mixture into a suspension by ultrasonic stirring. The particle size of the PLLA powder is 20-80μm, the viscosity is 1.8-2.5dL / g, the melting point is 170-185°C, the ultrasonic dispersion time is 30-60min, and the ultrasonic dispersion temperature is 40-60°C;

[0033] (2) Filtration: filter the suspension with a microporous membrane to obtain a mixed material;

[0034] (3) Drying: Dry the mixed material in a rotary dryer to obtain nHA / PLLA mixed powder. The drying temperature is 60-100°C. The mass percentage content of polylactic acid in the mixed powder is 90%, and the mass percentage content of hydroxyapatite is 10%.

[0035] 2. Selective laser sintering

[0036] (1) Preheating: spread the PLLA / nHA mixed powder on the laser sintering template, the thickness of each powder spreading is 0...

Embodiment 2

[0044] 1. Composite powder preparation

[0045] (1) Mixing: Weigh PLLA, nHA, and MET according to 9:1:2. After physical mixing, place them in a beaker filled with absolute ethanol, and disperse the mixture into a suspension by ultrasonic stirring. The particle size of the PLLA powder is 20-80μm, the viscosity is 1.8-2.5dL / g, the melting point is 170-185°C, the ultrasonic dispersion time is 30-60min, and the ultrasonic dispersion temperature is 40-60°C;

[0046](2) Filtration: filter the suspension with a microporous membrane to obtain a mixed material;

[0047] (3) Drying: Dry the mixed material in a rotary dryer to obtain MET / nHA / PLLA mixed powder. The drying temperature is 60-100°C. The mass percentage content of polylactic acid in the mixed powder is 75%, the mass percentage content of hydroxyapatite is 8.3%, and the mass percentage content of metformin is 16.7%.

[0048] 2. Selective laser sintering

[0049] (1) Preheating: Spread the MET / PLLA / nHA mixed powder on the l...

Embodiment 3

[0058] 1. Composite powder preparation

[0059] (1) Mixing: Weigh PLLA, nHA, and MET according to 9:1:4. After physical mixing, place them in a beaker filled with absolute ethanol, and disperse the mixture into a suspension by ultrasonic stirring. The particle size of the PLLA powder is 20-80μm, the viscosity is 1.8-2.5dL / g, the melting point is 170-185°C, the ultrasonic dispersion time is 30-60min, and the ultrasonic dispersion temperature is 40-60°C;

[0060] (2) Filtration: filter the suspension with a microporous membrane to obtain a mixed material;

[0061] (3) Drying: Dry the mixed material in a rotary dryer to obtain MET / nHA / PLLA mixed powder. The drying temperature is 60-100°C. The mass percentage content of polylactic acid in the mixed powder is 64.3%, the mass percentage content of hydroxyapatite is 7.1%, and the mass percentage content of metformin is 28.6%.

[0062] 2. Selective laser sintering

[0063] (1) Preheating: Spread the MET / PLLA / nHA mixed powder on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com