Keratin nano-flower material loaded with silver phosphate and preparation and application thereof

A technology of keratin and nanoflowers, applied in organic compound/hydride/coordination complex catalysts, color/spectral characteristic measurement, physical/chemical process catalysts, etc., can solve inaccurate physical and chemical properties, complex synthesis process , small amount of synthesis, etc., to achieve the effect of simple and efficient preparation method, good selectivity and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

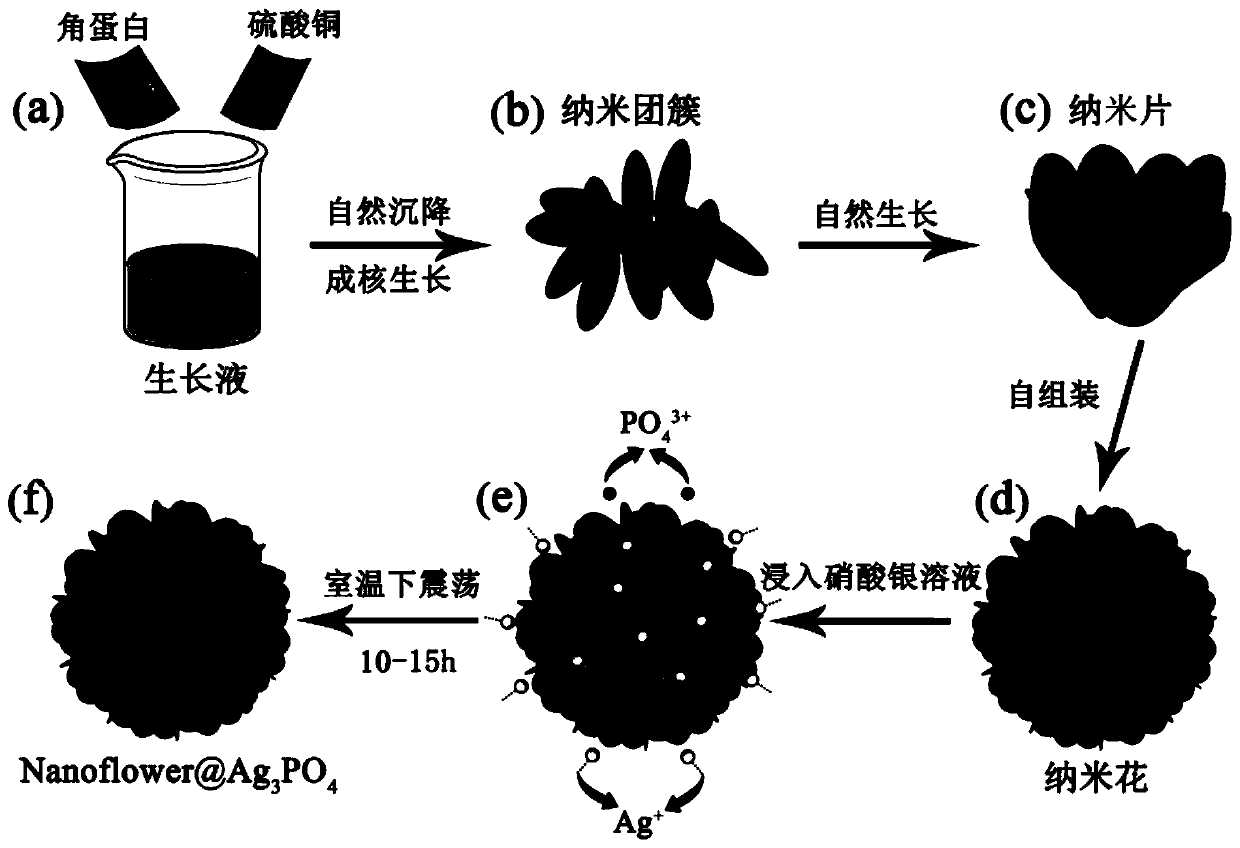

[0039] Such as figure 1 Shown, Keratin-nanoflower@Ag 3 PO 4 The synthesis process is as follows:

[0040] (1) Preparation of Keratin-nanoflower nanoflowers

[0041] ① Accurately weigh 3mg of keratin and dissolve it in PBS phosphate buffer solution (0.1M, pH=7.4);

[0042] ② After mixing evenly, add 200μL (120mM) CuSO to the above solution 4 Solution, rotate and shake the solution, then transfer the centrifuge tube to an electric heating constant temperature water tank at 25°C, and let it settle naturally for 72 hours;

[0043] ③ After centrifuging at 8000rpm for 3 minutes, remove the supernatant, wash the precipitate three times with distilled water, and finally place the obtained precipitate in a vacuum drying oven at 35°C for 12 hours.

[0044] (2) Keratin-nanofower@Ag 3 PO 4 preparation of

[0045] ① Accurately weigh the Keratin-nanoflower (5 mg) synthesized above and disperse it in deionized water;

[0046] ②Weigh again 15mg AgNO 3 dispersed in deionized water; ...

Embodiment 2

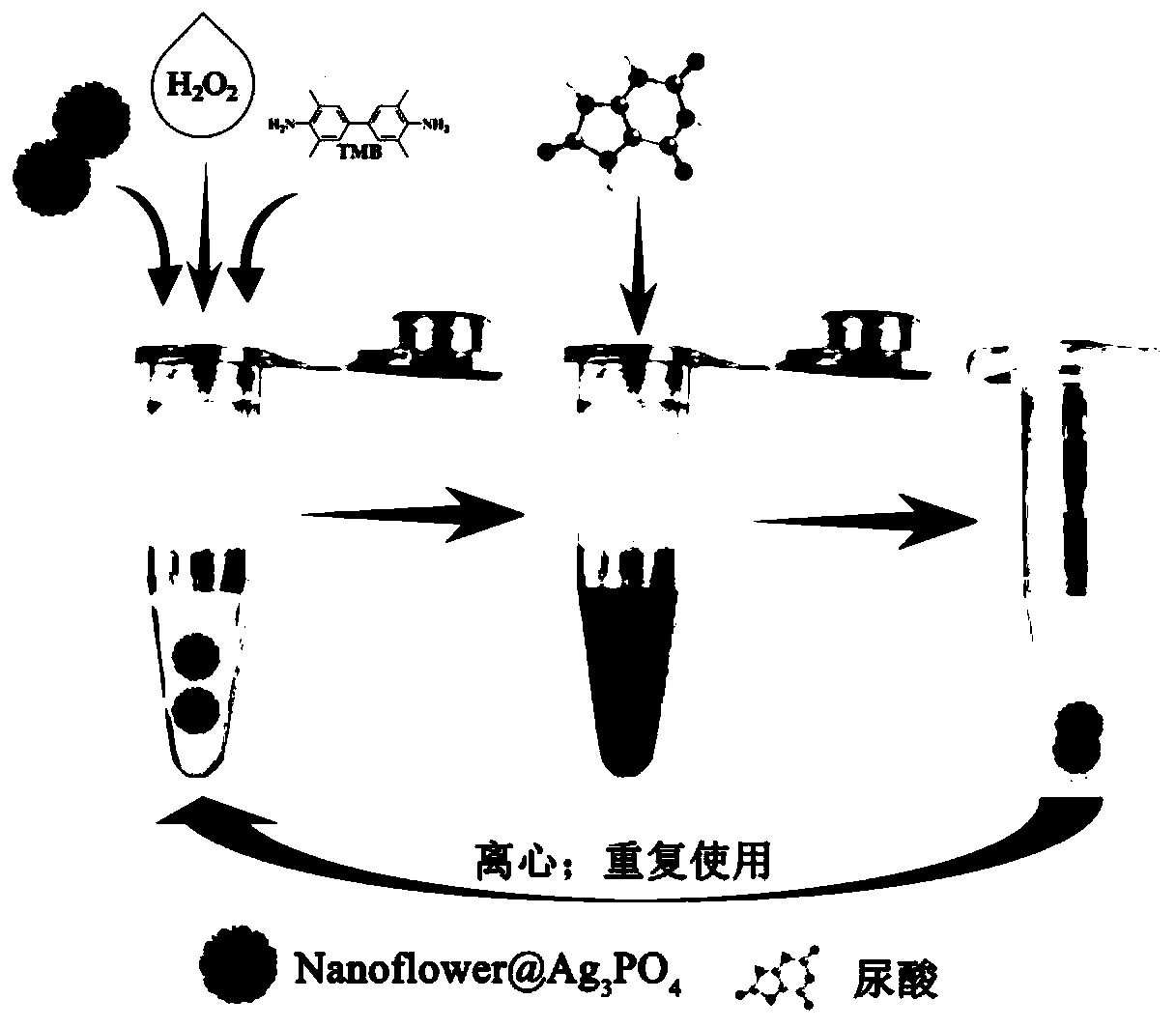

[0053] To Keratin-nanoflower@Ag 3 PO 4 The conditions for catalyzing the oxidation of its substrate by hydrogen peroxide were optimized, among which, Keratin-nanoflower@Ag 3 PO 4 Schematic diagram of colorimetric detection of uric acid figure 2 shown.

[0054] Leverage Keratin-nanoflower@Ag 3 PO 4 The steps of colorimetric detection of uric acid are as follows:

[0055]

Embodiment 21

[0057] Effect of reaction temperature on Keratin-nanoflower@Ag 3 PO 4 Solution Colorimetric Detection of Uric Acid Effect

[0058] (1) Take 360 μL of acetic acid-sodium acetate buffer solution (0.2M, pH=4.00) in a 1.5mL centrifuge tube, and add 20 μL of Keratin-nanoflower@Ag to the centrifuge tube in turn 3 PO 4 (2.5mg / mL), 20 μL hydrogen peroxide aqueous solution (5.0mM), 3,3',5,5'-tetramethylbenzidine (TMB, 2.0mM), mix the above solutions evenly;

[0059] (2) Take part of the mixed solution obtained in step (1) and react in a water bath (20°C, 30°C, 40°C, 50°C, 60°C, 70°C, 80°C) for 8 minutes;

[0060] (3) Keratin-nanoflower@Ag was passed through a centrifuge 3 PO 4 Separated from the reaction solution;

[0061] (4) Measure the ultraviolet absorption spectrum of the above mixed solution with an ultraviolet-visible absorption spectrophotometer.

[0062] Experimental results such as Image 6 As shown, it can be seen from the figure that the absorbance at 652nm increa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com