Method for preparing tetrahydrofurfuryl alcohol, and supported nickel catalyst

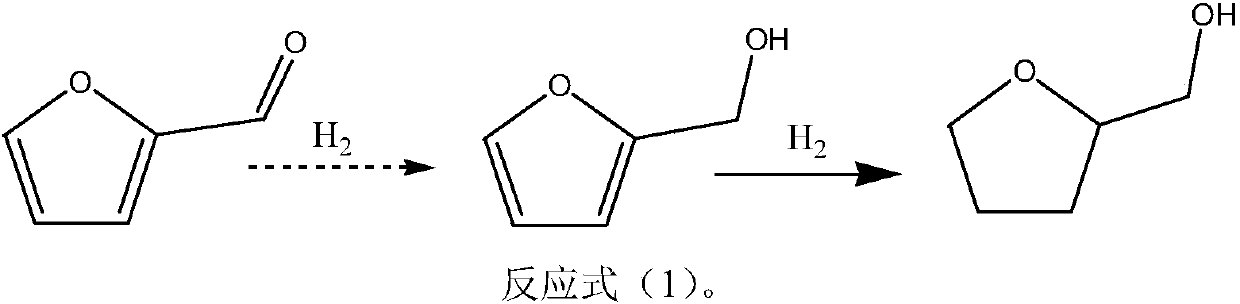

A technology of tetrahydrofurfuryl alcohol and nickel catalyst, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., which can solve the problem that the catalyst cannot be directly recycled and the production process is dangerous high energy consumption of the reaction process, etc., to achieve the effect of mild reaction conditions, high yield and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

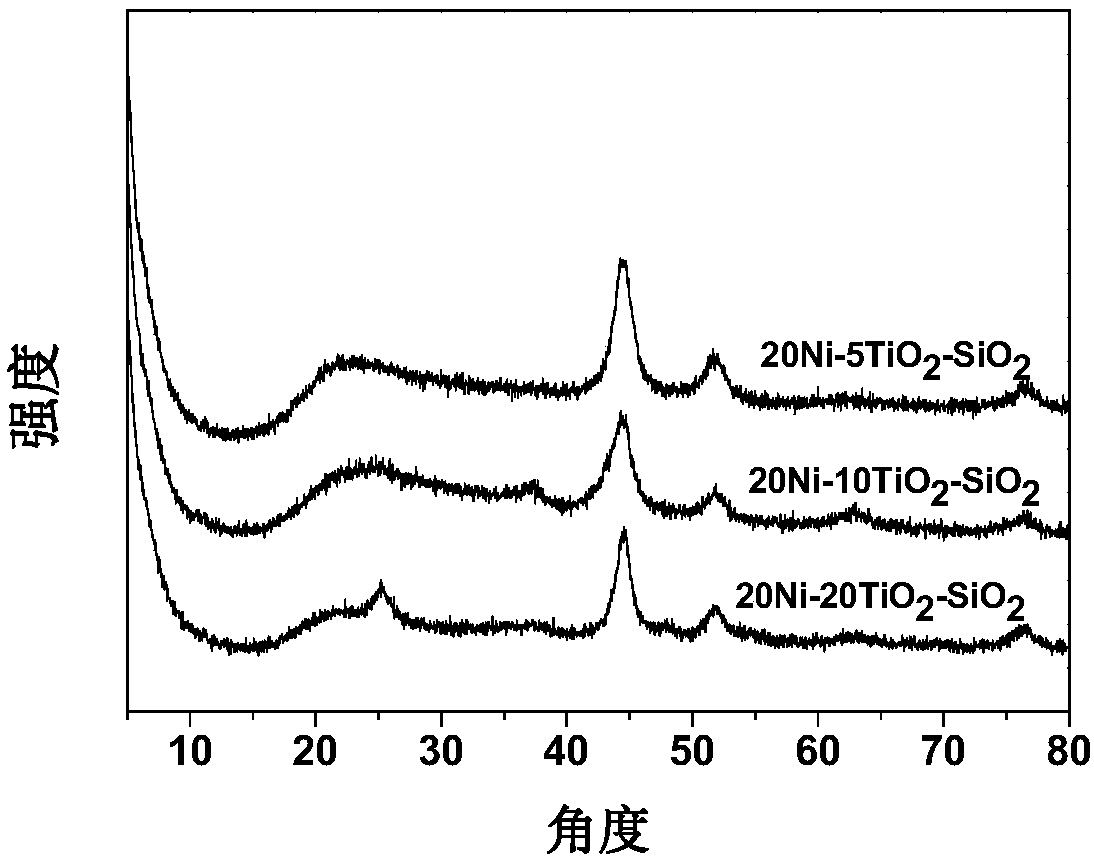

[0042] The preparation of embodiment 1 supported nickel catalyst

[0043] The silica carrier was uniformly dispersed in isopropanol solution, and tetrabutyl titanate (TiO 2 : SiO 2 =0.1, mass ratio), stirred overnight, suction filtered, oven-dried at 80°C for 12h, taken out and placed in a tube furnace for 2h at 500°C, with a heating rate of 3°C / min, to obtain 10TiO 2 / SiO 2 . Then use the excess impregnation method to load nickel, and disperse nickel nitrate hexahydrate in an appropriate amount of water (Ni: 10TiO 2 / SiO 2 =0.2, mass ratio), add ethylene glycol to control the particle size (ethylene glycol: metal nickel=5, molar ratio), stir evenly, add the obtained carrier 10TiO 2 / SiO 2 , stirred at 60°C until the solution was evaporated to dryness, dried in an oven at 80°C for 12 hours, took it out and put it in a tube furnace for 2 hours at 500°C, with a heating rate of 3°C / min, and then reduced it in hydrogen at 650°C for 2 hours, at a heating rate of 5°C / min, to o...

Embodiment 2

[0046] Use the catalyst prepared in Example 1 to prepare tetrahydrofurfuryl alcohol by furfural hydrogenation, and load catalyst 20Ni-5TiO in fixed bed 2 / SiO 2 , add raw material furfural, solvent ethanol, solvent dilution ratio is about 99:1 (water: furfural, volume ratio), reaction temperature is 90 ℃, hydrogen pressure 1MPa, hydrogen flow rate is 60ml / min, raw material flow rate is 0.05ml / min, The flow rate ratio of the supported nickel catalyst to the raw material is W / F=20g*min / mL, the catalytic activity remains stable within eight hours, the conversion rate of furfural remains 100%, and the selectivity of the target product remains 100%. Embodiment 3 furfural hydrogenation reaction

Embodiment 3

[0047] Use the catalyst prepared in Example 1 to prepare tetrahydrofurfuryl alcohol by furfural hydrogenation, and load catalyst 20Ni-5TiO in fixed bed 2 / SiO 2 , add raw material furfural, solvent ethanol, solvent dilution ratio is about 99:1 (water: furfural, volume ratio), reaction temperature is 90 ℃, hydrogen pressure 1MPa, hydrogen flow rate is 60ml / min, raw material flow rate is 0.1ml / min, The flow rate ratio of the supported nickel catalyst to the raw material W / F=10g*min / mL, the catalytic activity remained stable within eight hours, the conversion rate of furfural remained at 99%, and the selectivity of the target product remained at 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com