Novel battery pole piece enhancing method and corresponding pole piece

A battery pole piece and pole piece technology, which is applied in the field of new battery pole piece enhancement methods and corresponding pole pieces, can solve the problems of inability to meet the requirements of new binders, and the inhibition effect is not obvious, so as to enhance mechanical properties and reduce contact area, the effect of improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] In general, the binder compounding and pole piece preparation method involved in the present invention may include the following steps:

[0030] S1: Take a certain amount of conventional water-based binder and dissolve it in water;

[0031] S2: dissolving a certain amount of polyurethane in nitrogen methylpyrrolidone (NMP) or nitrogen nitrogen dimethylformamide (DMF);

[0032] S3: Mix the binder obtained in S1, the conductive carbon black, and the alloy negative electrode in a certain proportion, and grind them into a slurry.

[0033] S4: The slurry obtained in S3 is evenly coated on the surface of the copper foil, and then placed in a vacuum drying oven to dry for a certain period of time.

[0034] S5: Soak the pole piece obtained in S4 in the polyurethane solution prepared in S2, take it out for a certain period of time and vacuum dry it, and obtain an electrode piece with enhanced mechanical properties.

Embodiment 1

[0037] Include the following steps:

[0038] S1: Dissolve 500 mg of sodium polyacrylate (PAA-Na) in 10 mL of water to prepare a 50 mg / mL binder.

[0039] S2: Dissolve 50 mg of polyurethane in 10 mL of nitrogen-methylpyrrolidone (NMP) to prepare a 5 mg / mL solution.

[0040] S3: Mix the binder obtained in S1, conductive carbon black and silicon powder (300nm) in a certain mass ratio, and grind them into a slurry (silicon / carbon black / PAA-Na mass ratio=80 / 10 / 10).

[0041] S4: The slurry obtained in S3 is evenly coated on the surface of the copper foil, and then placed in a vacuum drying oven at 80°C for 12 hours.

[0042] S5: Cut the pole pieces obtained in S4 into small discs with a certain diameter, then soak them in the polyurethane solution prepared in S2, take them out after 5 hours, and dry them in vacuum at 80 degrees.

[0043] S6: Assemble a lithium-ion battery by using metallic lithium as a counter electrode for the pole piece obtained in S5.

Embodiment 3

[0051] Include the following steps:

[0052]S1: Dissolve 150 mg of sodium carboxymethylcellulose (CMC) and 150 mg of styrene-butadiene rubber (SBR) binder in 10 mL of water, respectively.

[0053] S2: Dissolve 300 mg of polyurethane in 10 mL of nitrogen methylpyrrolidone (NMP).

[0054] S3: Mix the binder obtained in S1, conductive carbon black and antimony in a certain proportion, and grind them into a slurry (mass ratio of antimony / carbon black / CMC / SBR=60 / 20 / 10 / 10).

[0055] S4: The slurry obtained in S3 is evenly coated on the surface of the copper foil, and then placed in a vacuum drying oven at 80°C for 12 hours.

[0056] S5: Cut the pole pieces obtained in S4 into small discs with a certain diameter, then soak them in the polyurethane solution prepared in S2, take them out after 12 hours, and dry them in vacuum at 80 degrees.

[0057] S6: Assemble a sodium ion battery by using metallic sodium as a counter electrode on the pole piece obtained in S5.

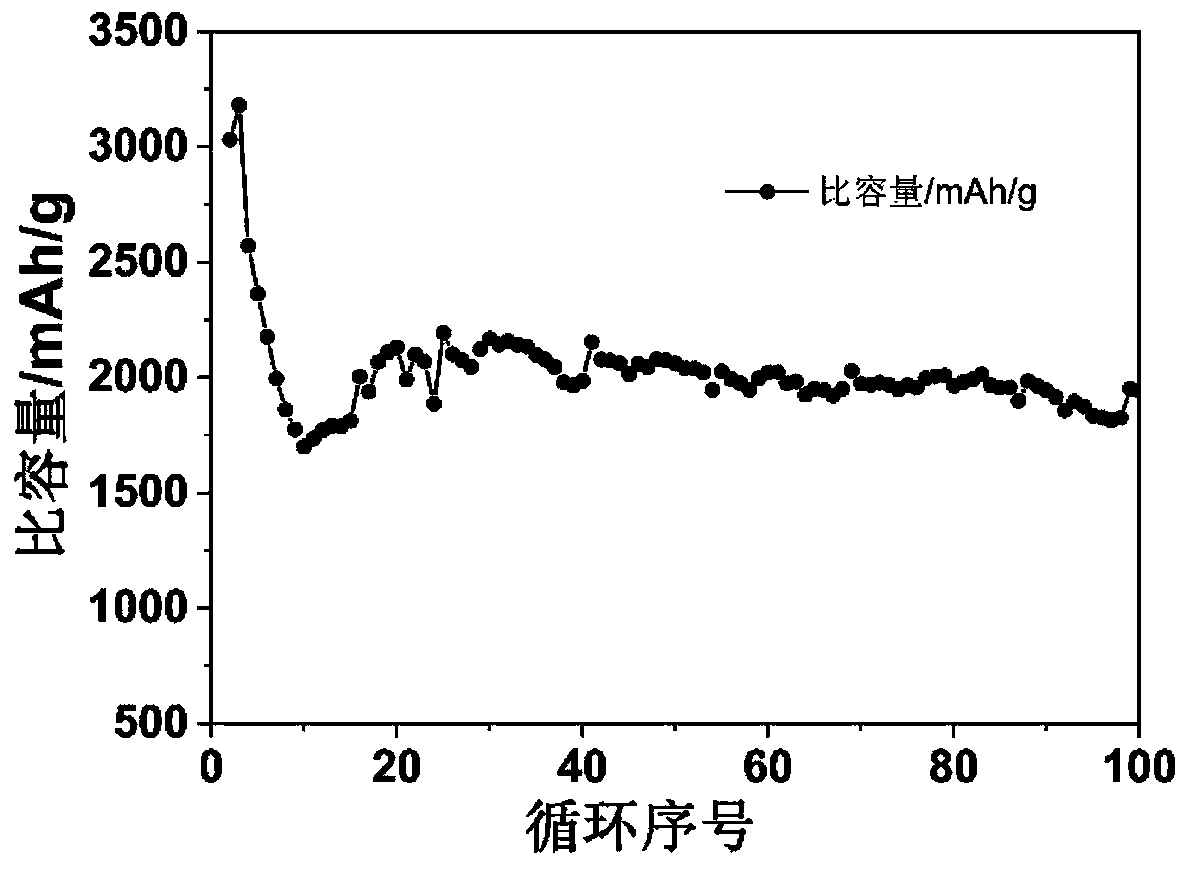

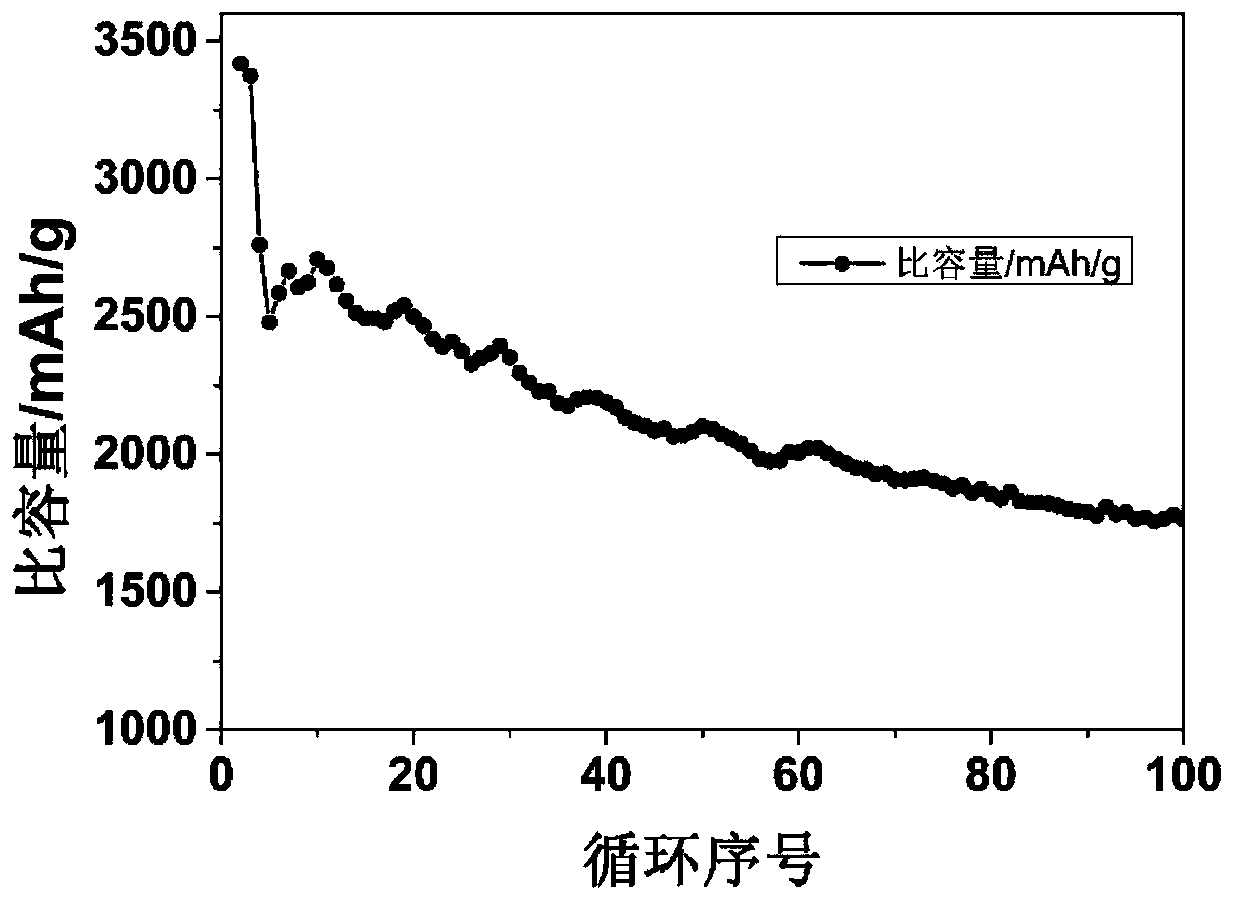

[0058] figure 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com