Metal-semiconductor composite photocatalyst for photocatalytic synthesis for preparing ammonia gas from nitrogen and hydrogen, and preparation method and applications thereof

A photocatalysis and semiconductor technology, applied in the field of preparation, metal-semiconductor composite photocatalyst, can solve the problems of inefficient ammonia synthesis, unfavorable ammonia gas efficiency, inefficient interface electron transfer, etc., to reduce environmental pollution, reduce energy consumption, The effect of saving synthesis costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

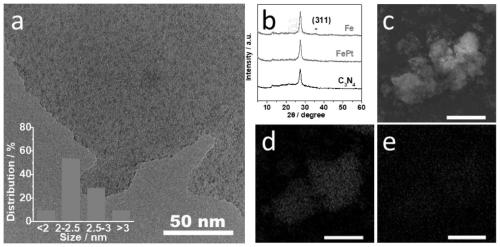

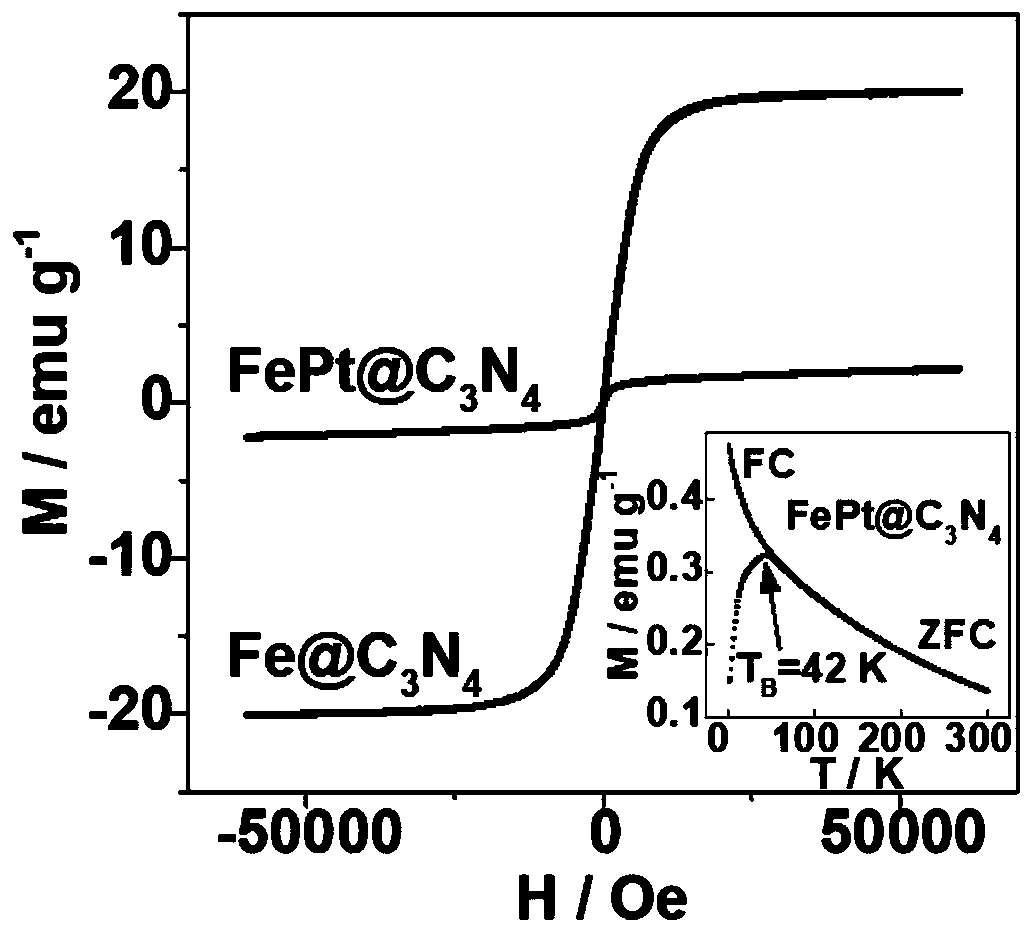

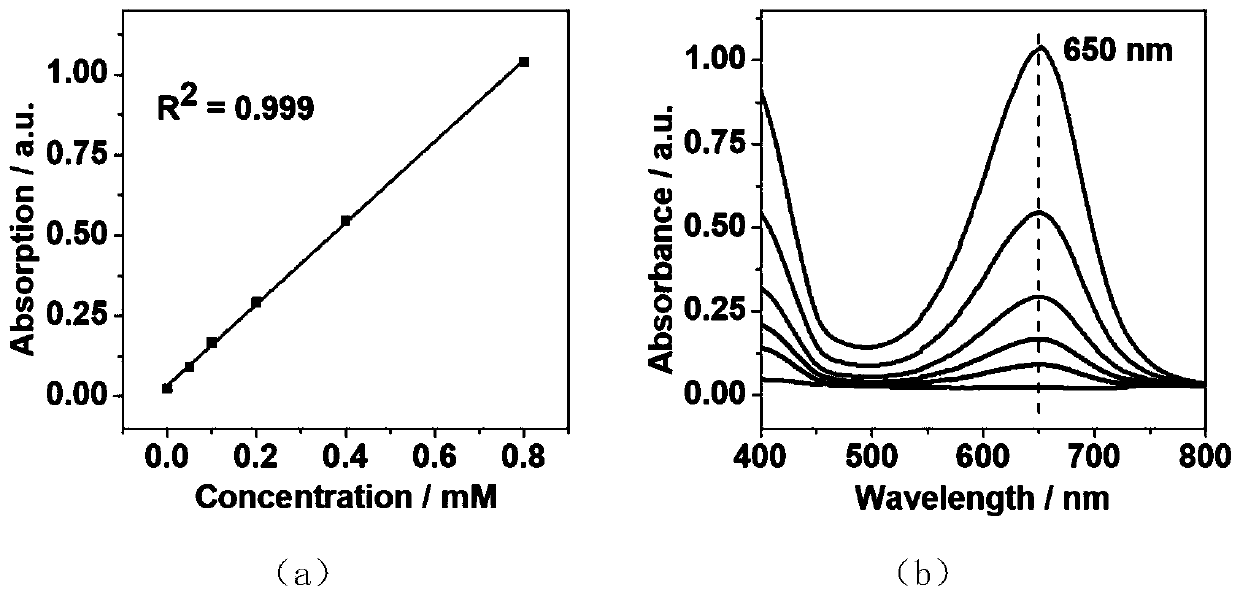

[0023] Iron-platinum nanocluster doped graphitic carbon nitride (g-C 3 N 4 ) photocatalyst (named FePt@C 3 N 4 ), and catalyzed N under light conditions 2 and H 2 Synthetic NH 3 .

[0024] (1) Preparation of graphite-phase carbon nitride: a high-temperature polymerization method is used to prepare graphite-phase carbon nitride using urea as a raw material. Weigh urea (10 g), then transfer the ground powder to a ceramic crucible, wrap the ceramic crucible with tin foil, place it in a muffle furnace, and calcinate it at 550 °C for 2 h with a heating rate of 5 °C / min to obtain the final product and named g-C 3 N 4 .

[0025] (2) Fe-Pt nanocluster doped graphitic carbon nitride (g-C 3 N 4 ) catalyst (named FePt@C 3 N 4 ) preparation: 15mg dodecacarbonyl iron (Fe 3 (CO) 12 ) was dissolved in 10mL of anhydrous tetrahydrofuran (THF), and then mixed with 50mg of g-C 3 N 4 Mix and then concentrate the solution to 1 mL by rotary evaporation. Then add 1.3mg of hexachlor...

Embodiment 2

[0028] Iron-platinum nanocluster doped graphitic carbon nitride (g-C 3 N 4 ) photocatalyst (named FePt@C 3 N 4 ), and catalyzed N under light conditions 2 and H 2 Synthetic NH 3 .

[0029] (1) Preparation of graphite phase carbon nitride: the same as in Example 1.

[0030] (2) Fe-Pt nanocluster doped graphitic carbon nitride (g-C 3 N 4 ) catalyst (named FePt@C 3 N 4 ) preparation: 3mg dodecacarbonyl iron (Fe 3 (CO) 12 ) was dissolved in 10mL of anhydrous tetrahydrofuran (THF), and then mixed with 50mg of g-C 3 N 4 Mix and then concentrate the solution to 1 mL by rotary evaporation. Then add 0.3mg of hexachloroplatinic acid, sonicate the solution and spread it on the bottom of the quartz reactor, completely remove the THF solvent by a diaphragm pump, and then completely remove the carbonyl group in the raw material under vacuum at high temperature (220°C), and finally obtain 50.33mg catalyst of light.

[0031] (3) Photocatalytic ammonia synthesis: 50.33 mg of ph...

Embodiment 3

[0033] Iron-platinum nanocluster doped graphitic carbon nitride (g-C 3 N 4 ) photocatalyst (named FePt@C 3 N 4 ), and catalyzed N under light conditions 2 and H 2 Synthetic NH 3 .

[0034] (1) Preparation of graphite phase carbon nitride: the same as in Example 1.

[0035] (2) Fe-Pt nanocluster doped graphitic carbon nitride (g-C 3 N 4 ) catalyst (named FePt@C 3 N 4 ) preparation: 3mg dodecacarbonyl iron (Fe 3 (CO) 12 ) was dissolved in 10mL of anhydrous tetrahydrofuran (THF), and then mixed with 50mg of g-C 3 N 4 Mix and then concentrate the solution to 1 mL by rotary evaporation. Then add 3 mg of hexachloroplatinic acid, ultrasonicate the solution and spread it on the bottom of the quartz reactor, completely remove the THF solvent by a diaphragm pump, and then completely remove the carbonyl in the raw material under vacuum at high temperature (220 ° C), and finally obtain 50.6 mg of light catalyst.

[0036] (3) Photocatalytic ammonia synthesis: 50.6 mg of pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com