A method for removing arsenic from arsenic dust

An arsenic fume and arsenic removal technology, applied in chemical instruments and methods, arsenate/arsenite, arsenic compounds, etc., can solve the problems of valuable metals, long process, difficult to completely capture arsenic fume, etc. Achieve the effect of saving energy consumption and simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

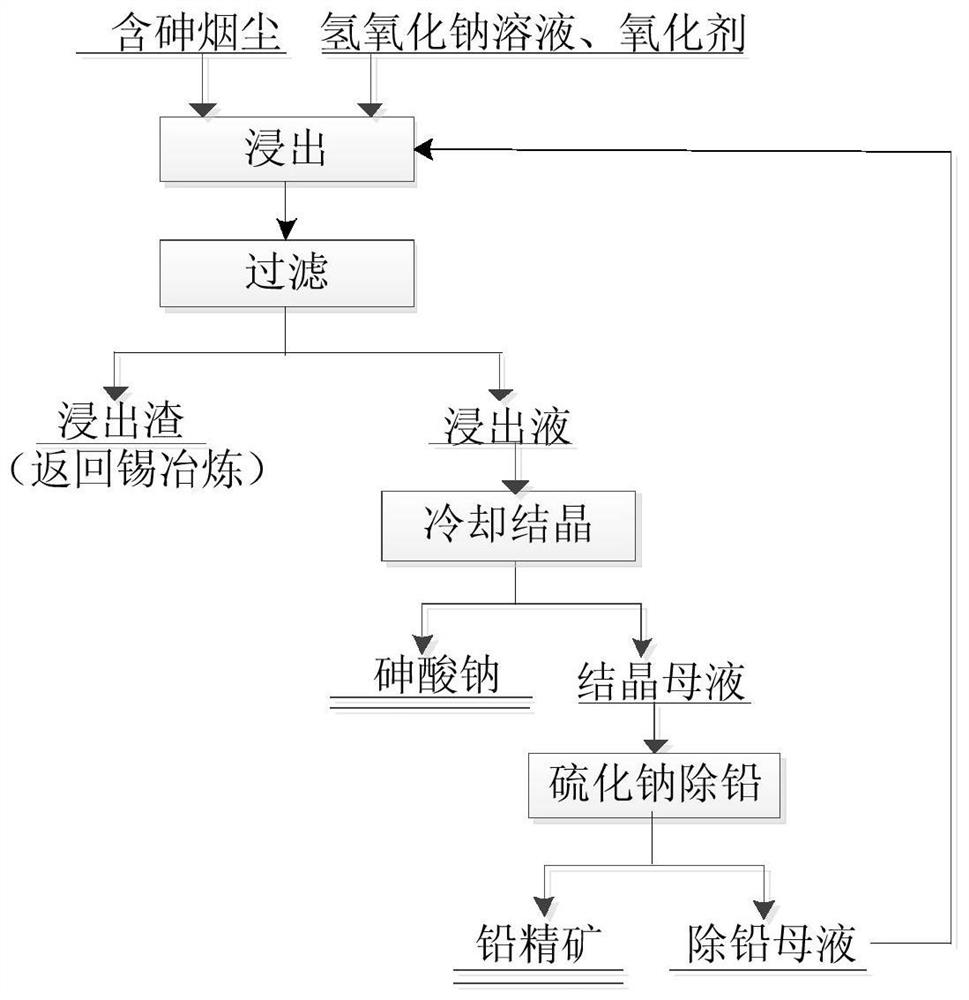

[0027] A method for wet treatment of arsenic-containing smoke, the treatment method is as follows:

[0028] (1) leaching 500g of arsenic-containing smoke and dust containing 13.3% arsenic, 26.6% tin, 2.72% indium, and 7.95% lead, using sodium hydroxide and sodium chlorate, leaching conditions: sodium hydroxide concentration 80g / L, liquid-solid volume The mass ratio is 10:1 (ml:g), the reaction temperature is 90°C, the amount of sodium chlorate is 0.3 times the mass of arsenic in the flue dust, and the reaction time is 4 hours to obtain 4.8L of sodium arsenate solution and leaching residue. Add water to wash and filter to obtain 326g of tin concentrate containing 40.5% Sn, 4.15% indium and 1.37% arsenic;

[0029] (2) The leachate was cooled to 20-25° C., filtered and separated to obtain 4.6 L of crystallization mother liquor containing 2.1 g / L of arsenic and 5.72 g / L of lead, and 325 g of sodium arsenate with a content of 91.6%;

[0030] (3) Add 2 times the theoretical amount ...

Embodiment 2

[0032] A method for wet treatment of arsenic-containing smoke, the treatment method is as follows:

[0033] (1) leaching 500g of arsenic-containing smoke dust containing 19.8% of arsenic, 24.3% of tin, 3.2% of indium, and 6.6% of lead, using sodium hydroxide and potassium permanganate, leaching conditions: sodium hydroxide concentration 200g / L, liquid-solid The volume-to-mass ratio is 6:1 (ml:g), the reaction temperature is 95°C, the reaction time is 2 hours, and the amount of potassium permanganate is 0.5 times the mass of arsenic in the smoke to obtain 2.85L of sodium arsenate solution and 312g of leaching residue. The leaching residue was washed with water, filtered to obtain a tin concentrate containing 39.6% of Sn, 5.1% of indium, and 1.48% of arsenic;

[0034] (2) Cooling and crystallization of the leachate, the leachate was cooled to 20-25°C, filtered and separated to obtain 2.65L crystallization mother liquor containing 3.2g / L arsenic and 8.7g / L lead, and 508g of sodiu...

Embodiment 3

[0037] A method for wet treatment of arsenic-containing smoke, the treatment method is as follows:

[0038] (1) 500g of arsenic-containing fumes containing 10.2% of arsenic, 28.8% of tin, 3.5% of indium, and 5.3% of lead are leached with sodium hydroxide and hydrogen peroxide, leaching conditions: leaching conditions: sodium hydroxide concentration 150g / L, liquid-solid The volume to mass ratio is 4:1 (ml:g), the reaction temperature is 60°C, the reaction time is 6 hours, the amount of hydrogen peroxide is 0.6 times the mass of arsenic in the smoke, and 1.86L of sodium arsenate solution and 324g of leaching residue are obtained. The leaching residue is water After washing and filtering, a tin concentrate containing 43.9% tin, 5.35% indium and 1.18% arsenic was obtained;

[0039] (2) Cooling and crystallization of the leachate, the leachate was cooled to 20-25°C, filtered and separated to obtain 1.65L crystallization mother liquor containing 2.5g / L of arsenic and 10.6g / L of lead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com