Micro-nanostructured lithium-sulfur battery composite cathode material, preparation method thereof and battery

A composite positive electrode material and battery technology, applied in battery electrodes, lithium batteries, nanotechnology for materials and surface science, etc., can solve the problems of polysulfide shuttle effect, slow conversion rate, low conductivity, etc., to achieve inhibition Shuttle effect, increase conversion rate, increase the effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

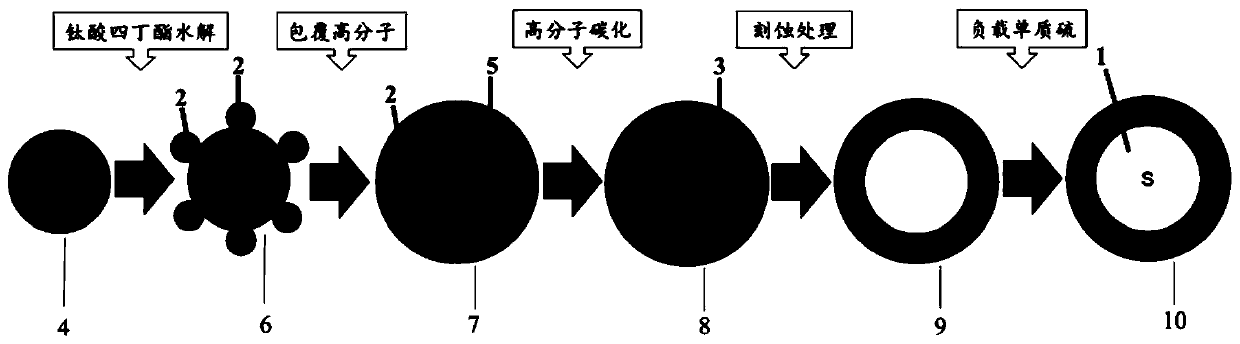

[0059] The present invention also provides a preparation method of battery composite cathode material, comprising the following steps:

[0060] a) Depositing titanium dioxide 2 on the surface of the microsphere 4 to obtain a composite microsphere 6 with titanium dioxide 2 deposited on the surface;

[0061] b) Coating the polymer 5 on the surface of the composite microsphere 6 to obtain the composite microsphere 6 coated with the polymer 5, and then carbonizing the composite microsphere 6 coated with the polymer 5 under a mixed atmosphere to carbonize the polymer 5 , to obtain heteroatom-doped carbon-coated composite microspheres 8;

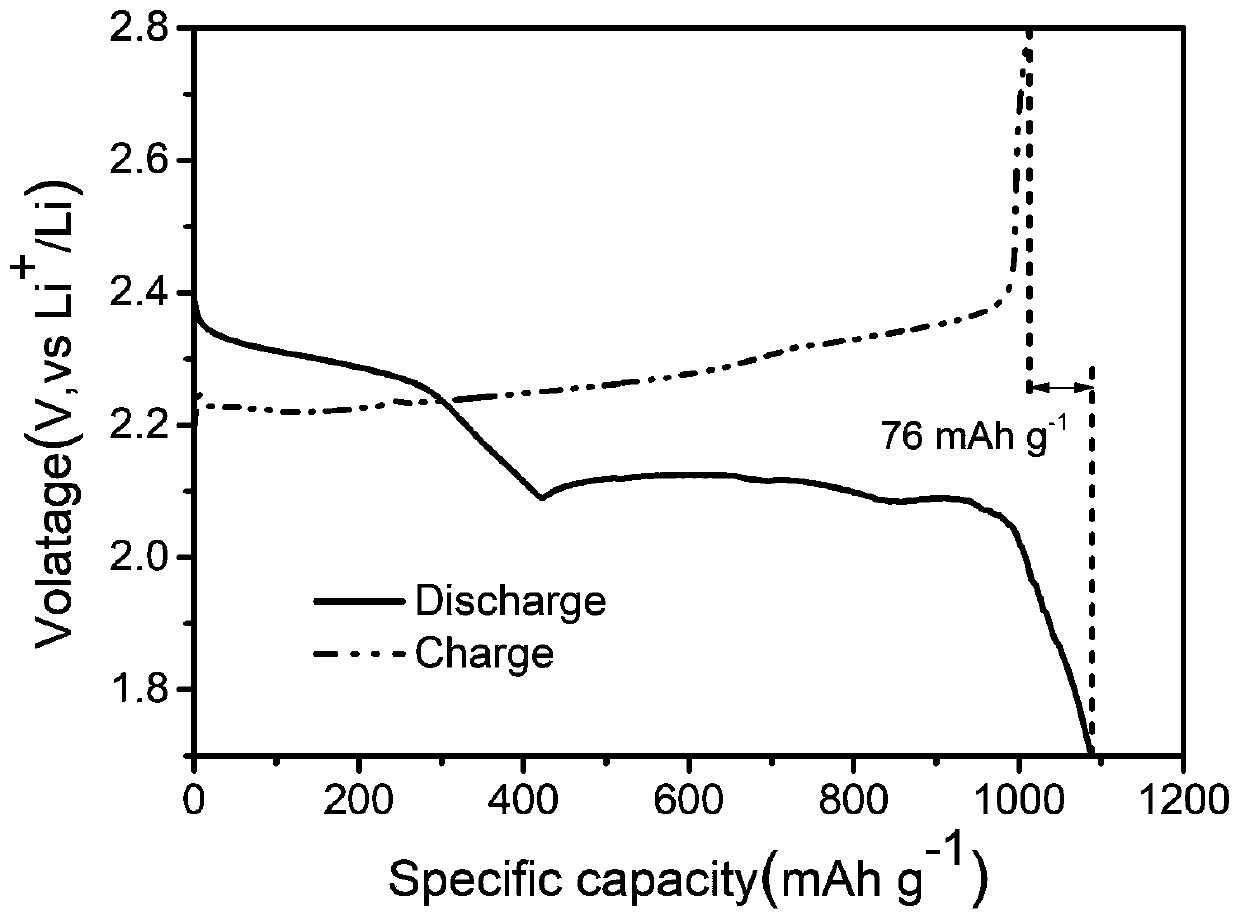

[0062] c) Etching the heteroatom-doped carbon-coated composite microspheres 8 to remove the microspheres to obtain a metal-carbon shell 9, and then load elemental sulfur in the metal-carbon shell 9, and the elemental sulfur is deposited on the metal-carbon shell Sulfur nucleus 1 is formed in 9 to obtain battery composite positive electrode materi...

Embodiment 1

[0095] This embodiment carries out the preparation of battery composite positive electrode material, comprises the following steps:

[0096] 1) Measure 20mL of deionized water, 70mL of absolute ethanol and 5mL of 30wt% ammonia water respectively, add them to the beaker in sequence, stir evenly with a magnetic stirrer at room temperature, weigh 1.0g of tetraethyl orthosilicate (TEOS) and slowly add it dropwise to In the uniformly mixed solution, seal the mouth of the beaker with a polyethylene film after the dropwise addition, and stir continuously at room temperature for 6 hours to complete the reaction, and then centrifugally wash to obtain SiO with different diameters. 2 Microspheres, SiO 2 The diameter of the microsphere is 100nm-300nm.

[0097] 2) Weighing 0.5 g of tetrabutyl titanate was added into deionized water, and stirred at room temperature to form a tetrabutyl titanate solution. Weigh another 0.2g SiO 2 The microspheres were dissolved in deionized water to obtai...

Embodiment 2

[0101] This embodiment carries out the preparation of battery composite positive electrode material, comprises the following steps:

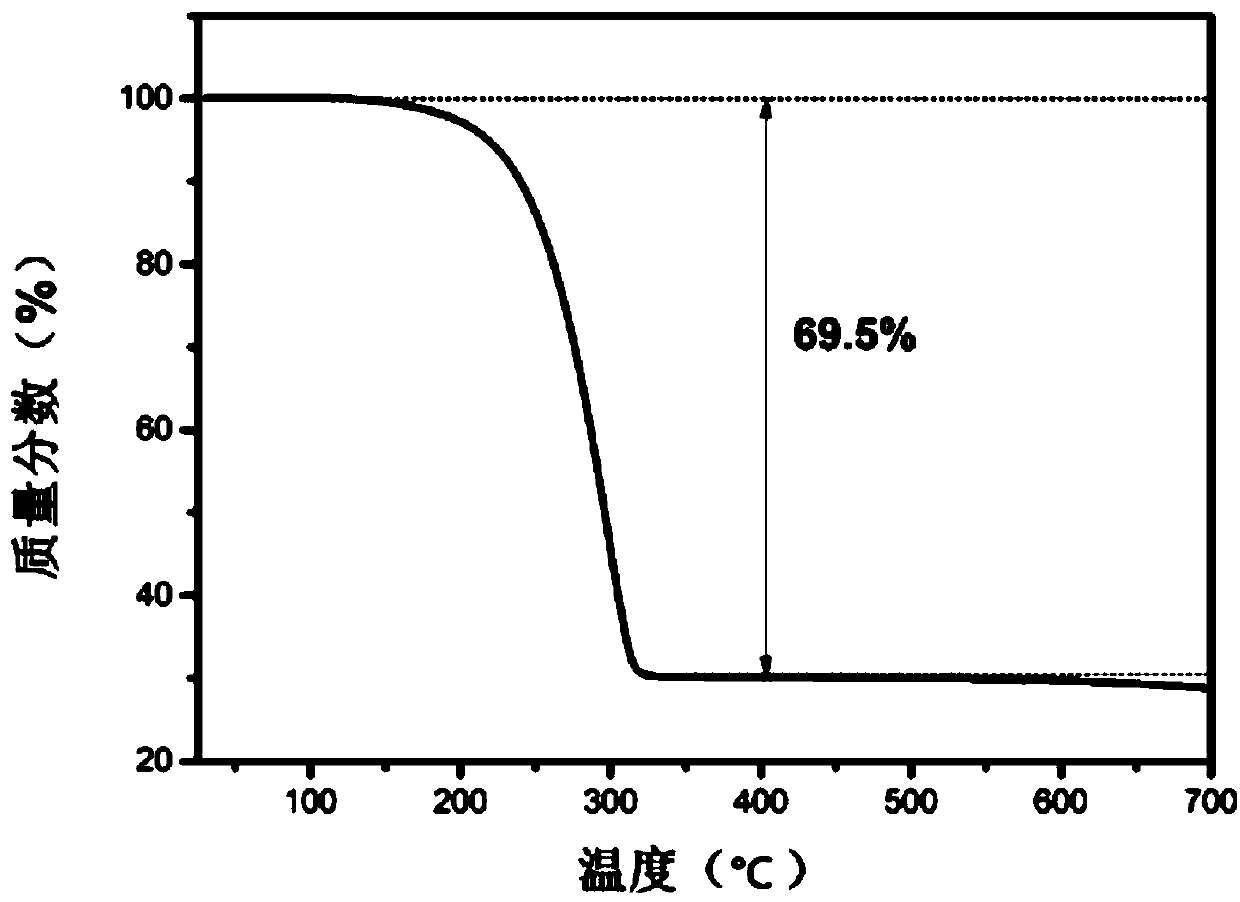

[0102] 1) Weigh 1.3g of polyacrylic acid and dissolve it in deionized water, add 1.0g of the composite microspheres prepared in Example 1, continue to stir at room temperature for 10h, centrifugally clean, and dry to obtain polymer-coated composite microspheres; The coated composite microspheres are placed in a tube furnace, and thiourea is placed on the upper tuyeres of the tube furnace, and the thiourea is decomposed by argon gas heated at a flow rate of 35mL / min. At this time, the tube furnace is filled with argon In a mixed atmosphere with hydrogen sulfide, heat up to 650°C at a heating rate of 3°C / min for 2.5h constant temperature carbonization treatment to carbonize polyacrylic acid to obtain composite microspheres coated with sulfur-doped carbon, with a sulfur-doped carbon content of 27%. , the pore diameter of the mesopores on the surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com