A kind of preparation method of aqueous solution redispersible cellulose nanofibril

A nanofibril and redispersion technology, applied in the field of cellulose, can solve the problems of not being able to effectively maintain the original performance and pollute the environment, and achieve the effect of universality, simple operation method and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

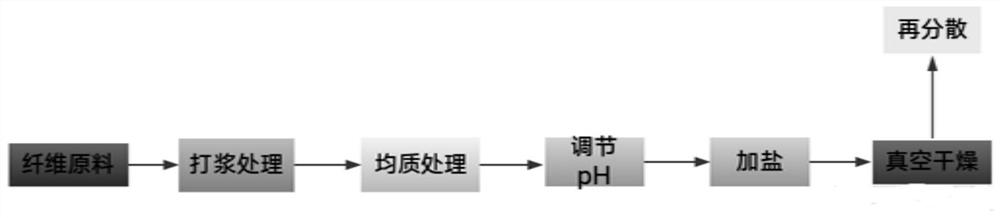

[0035] As introduced in the background art, the existing aqueous solution redispersible cellulose nanofibrils preparation technology will lead to the problem that the cellulose nanofibrils are modified to varying degrees and it is difficult to maintain the original properties. Therefore, the present invention proposes a method for preparing aqueous solution redispersible cellulose nanofibrils (CNF). Take the following steps:

[0036] (1) Beating treatment: the pulp decomposed by the fiber dissociation device is beaten by a beater.

[0037] (2) Nano-homogenization: after the slurry has been processed by the beater, at room temperature, it is first processed through a 200 μm chamber, and then passed through the 200 μm and 87 μm chambers for homogenization.

[0038] (3) pH adjustment: adjust the pH of the CNF suspension to be acidic with hydrochloric acid solution, and then adjust to alkaline with sodium hydroxide solution.

Embodiment 1

[0064] 1. Beating treatment, the pulp decomposed by the fiber disintegrator is put into the Valli beater at a pulp concentration of 10% and beat until the CSF is 100mL.

[0065] 2. For nano homogenization treatment, use a high-pressure micro-jet nano homogenizer. The processing conditions were: 10 passes through a 200 μm chamber at 200 bar, and then 15 passes through a 200 μm and 87 μm chamber at 1200 bar.

[0066] 3. pH adjustment, first adjust the pH of the CNF suspension to 3 with hydrochloric acid, then drop sodium hydroxide to adjust the pH to 8.

[0067] 4. Add potassium chloride to the CNF suspension and maintain the ionic strength at 10 mM.

[0068] 5. Drying treatment, using a vacuum drying oven to dry. Treatment conditions: -15bar, dry at 60°C for 2 days (see attachment for scanning electron microscope Figure 4 ).

[0069] 6. Redispersion, the dispersion conditions are: CNF 1%, shearing at 10000rpm for 15s. (SEM see attached Figure 5 ).

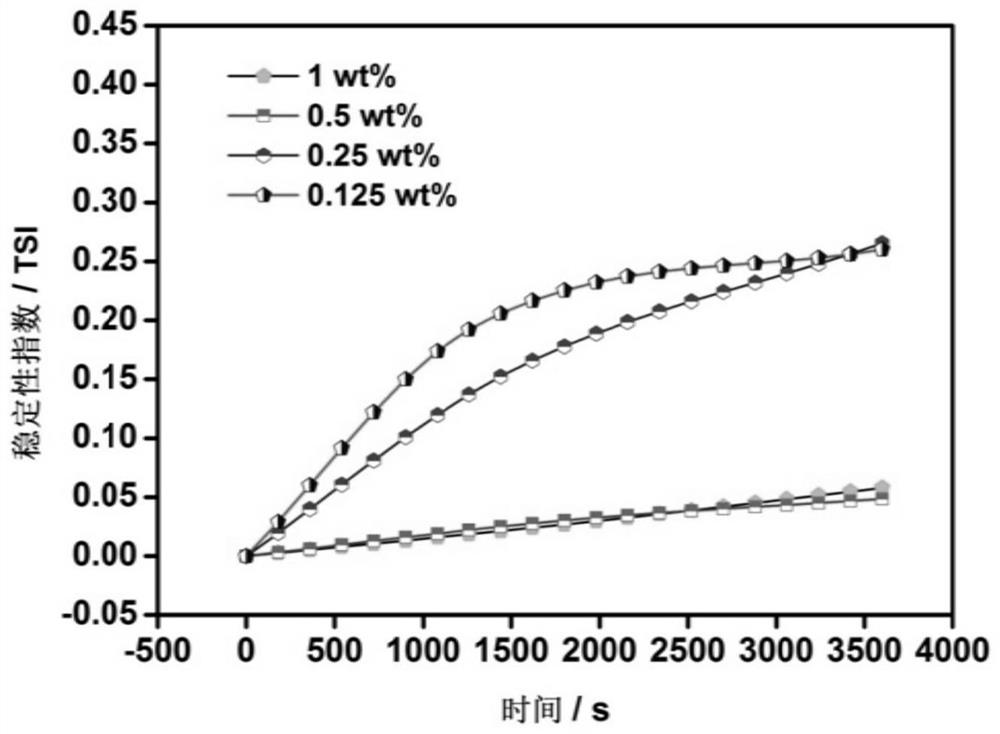

[0070] The redisper...

Embodiment 2

[0072] 1. Beating treatment, the pulp decomposed by the fiber disintegrator is put into the Valli beater with a pulp concentration of 20% to beat until the CSF is 50mL.

[0073] 2. For nano homogenization treatment, use a high-pressure micro-jet nano homogenizer. The processing conditions were: 15 passes through a 200 μm chamber at 300 bar, and then 25 passes through a 200 μm and 87 μm chamber at 1000 bar.

[0074] 3. pH adjustment, first adjust the pH of the CNF suspension to 4 with hydrochloric acid, then drop sodium hydroxide to adjust the pH to 8.

[0075] 4. Add potassium chloride to the CNF suspension and maintain the ionic strength at 15 mM.

[0076] 5. Drying treatment, drying in a vacuum oven. Treatment conditions: -10bar, 3 days drying at 55°C.

[0077] 6. Redispersion, the dispersion conditions are: CNF 0.5%, shearing at 11000rpm for 30s.

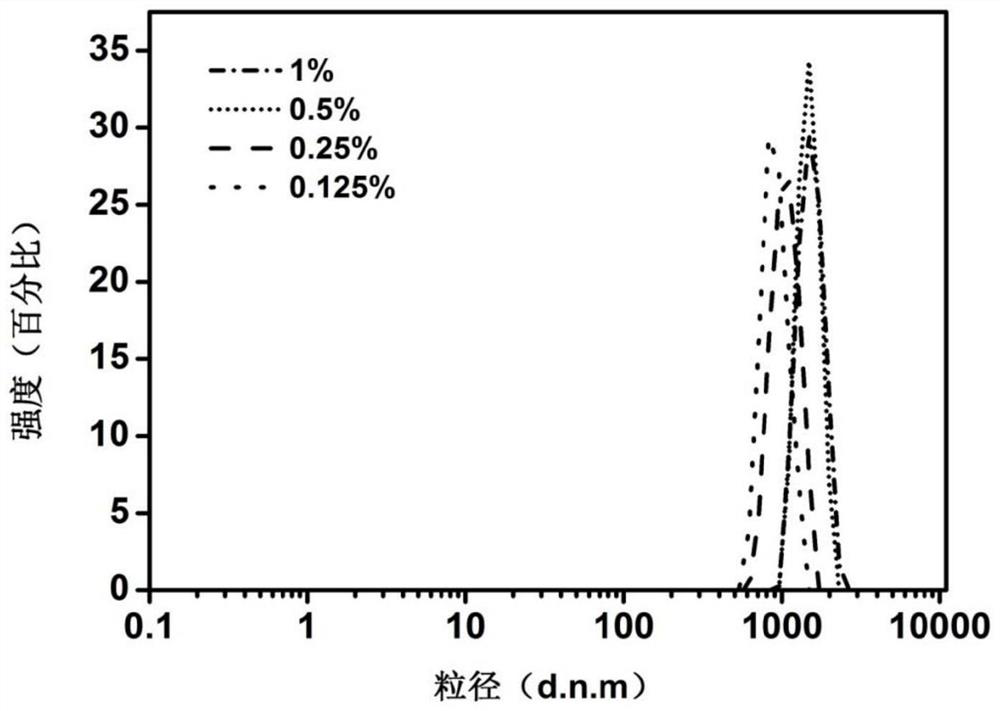

[0078] The redispersed particle diameter that this example makes is 1100~1990nm (see attached figure 2 ), the TSI is 0.0-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com