Etching liquid composition which does not contain fluorine

A technology of composition and etching solution, applied in the direction of surface etching composition, instrument, chemical instrument and method, etc., can solve problems such as waste water treatment cost, amorphous silicon damage, adverse effect of transistor driving characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 13 and comparative example 1 to 9

[0038] Examples 1 to 13 and Comparative Examples 1 to 9: Etching solution composition

[0039] The etching liquid compositions of Examples 1 to 13 and Comparative Examples 1 to 9 were prepared by mixing the respective components and the remaining water at the component contents described in Table 1 below.

[0040] In the following table 1, 5-methyltetrazole (5-Methyltetrazole) is used for the tetrazocyclic compound, malonic acid is used for the organic acid, and 3-amino-1,2,4-triazole- 5-thiol (3-Amino-1, 2, 4-triazole-5thiol), amines use diethanolamine (Diethanolamine), sulfonic acid compounds use methanesulfonic acid (Methanesulfonic acid), aromatic compounds use mandelic acid (Mandelic acid) ), and ammonium bifluoride (Ammonium bifluoride) is used as the fluorine compound.

[0041] Table 1

[0042]

experiment example 1

[0043] Experimental example 1. Determination of molybdenum residue and undercut

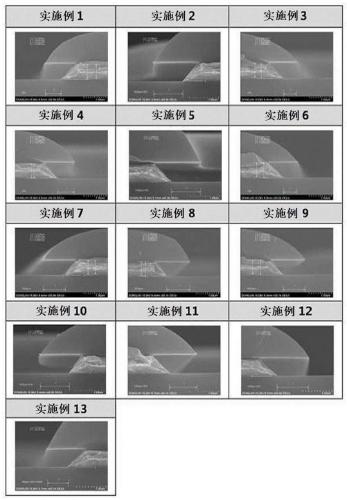

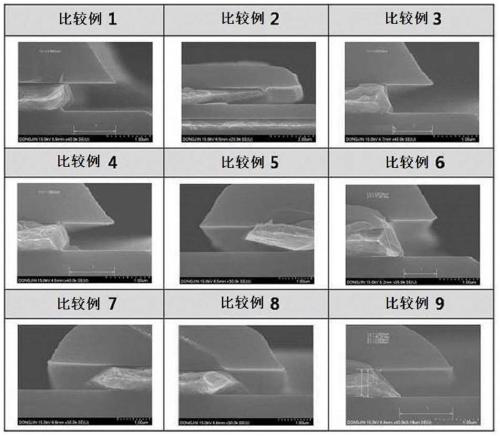

[0044] The vertical section of the sample including the laminated molybdenum / copper double film and photoresist pattern was etched with the etching composition of Examples 1 to 13 and Comparative Examples 1 to 9, and the molybdenum content of each sample was measured by scanning electron micrographs. After residue and undercut, record in following table 2, describe the scanning microscope photo for described embodiment and comparative example in the following figure 1 with figure 2 .

[0045] Table 2

[0046] Molybdenum residues undercut Example 1 none none Example 2 none none Example 3 none none Example 4 none none Example 5 none none Example 6 none none Example 7 none none Example 8 none none Example 9 none none Example 10 none none Example 11 none none Example 12 none no...

experiment example 2

[0048] Experimental example 2. Dimensional loss (CD-Loss) and etching rate measurement

[0049] If compare copper etching rate (Cu Etch Rate) and dimensional loss (CD-Loss), then the appropriate etching rate of described copper is / sec to / second, the dimensional loss is the distance between the end of the photoresist pattern and the end of the lower film or gate film, and for small height difference and uniform tapered etching, the dimensional loss ranges from 0.5 μm to 1.0 μm.

[0050] table 3

[0051]

[0052] Referring to the Table 3, when the content of the sulfonic acid compound exceeds the range of 1 wt % to 5 wt %, the molybdenum residue and undercut do not occur, and the dimensional loss and copper etching rate cannot reach an appropriate range.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap