Graphene color paste, preparation method thereof and application in fuel cells

A technology of graphene and color paste, which is applied in the field of graphene color paste and its preparation, can solve the problems of reduced electron transport characteristics, poor catalytic stability, high raw material cost, etc., to overcome expensive raw material costs, complete lattice structure, and guarantee The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

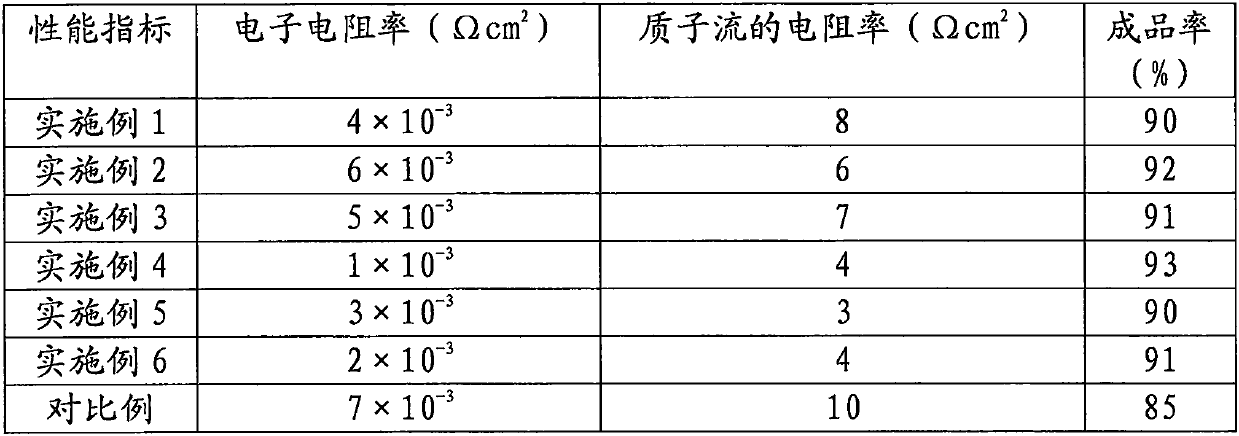

Examples

Embodiment 1

[0026] Graphene color paste: graphene powder 10g, polyacrylic acid sodium salt 1g, citrate 3g, butanol 4g, polysiloxane 1g, water 8g.

[0027] The preparation method of the graphene color paste adopting the above-mentioned raw materials: step (1): taking each of the above-mentioned raw materials;

[0028] Step (2): adding water, polyacrylic acid sodium salt, citrate, and butanol into a high-speed shear grinder, and performing pretreatment for 10 minutes to obtain material A;

[0029] Step (3): adding graphene powder to material A in step (2) and stirring at 40° C. for 15 minutes to obtain material B;

[0030] Step (4): adding the polysiloxane to the material B in the step (3) and stirring for 10 minutes to obtain the graphene color paste.

Embodiment 2

[0032] Graphene color paste: graphene powder 18g, polyethylene glycol 40010g, monoglyceride 5g, butyl acetate 10g, polyoxyethylene polyoxypropanolamine ether 3g, water 28g.

[0033] The preparation method of the graphene color paste adopting the above-mentioned raw materials: step (1): taking each of the above-mentioned raw materials;

[0034] Step (2): adding water, polyethylene glycol 400, monoglyceride, and butyl acetate into a high-speed shearing mill, and performing pretreatment for 10 minutes to obtain material A;

[0035] Step (3): adding graphene powder to material A in step (2) and stirring at 40° C. for 15 minutes to obtain material B;

[0036] Step (4): Add polyoxyethylene polyoxypropanol amine ether to the material B in step (3) and stir for 10 minutes to obtain graphene color paste.

Embodiment 3

[0038] Graphene color paste: 14g of graphene powder, 5g of polyacrylate, 4g of polyethylene wax, 7g of butyl acetate, 2g of polysiloxane, and 18g of water.

[0039] The preparation method of the graphene color paste adopting the above-mentioned raw materials: step (1): taking each of the above-mentioned raw materials;

[0040] Step (2): adding water, polyacrylate, polyethylene wax, and butyl acetate into a high-speed shear grinder, and performing pretreatment for 10 minutes to obtain material A;

[0041] Step (3): adding graphene powder to material A in step (2) and stirring at 40° C. for 15 minutes to obtain material B;

[0042] Step (4): Add the polysiloxane to the material B in the step (3) and stir for 10 min to obtain the graphene color paste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com