Nano-high-entropy alloy electrocatalyst and preparation method thereof

A high-entropy alloy, electrocatalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. Advanced problems, to achieve the effect of improving catalytic activity, promoting large-scale production, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

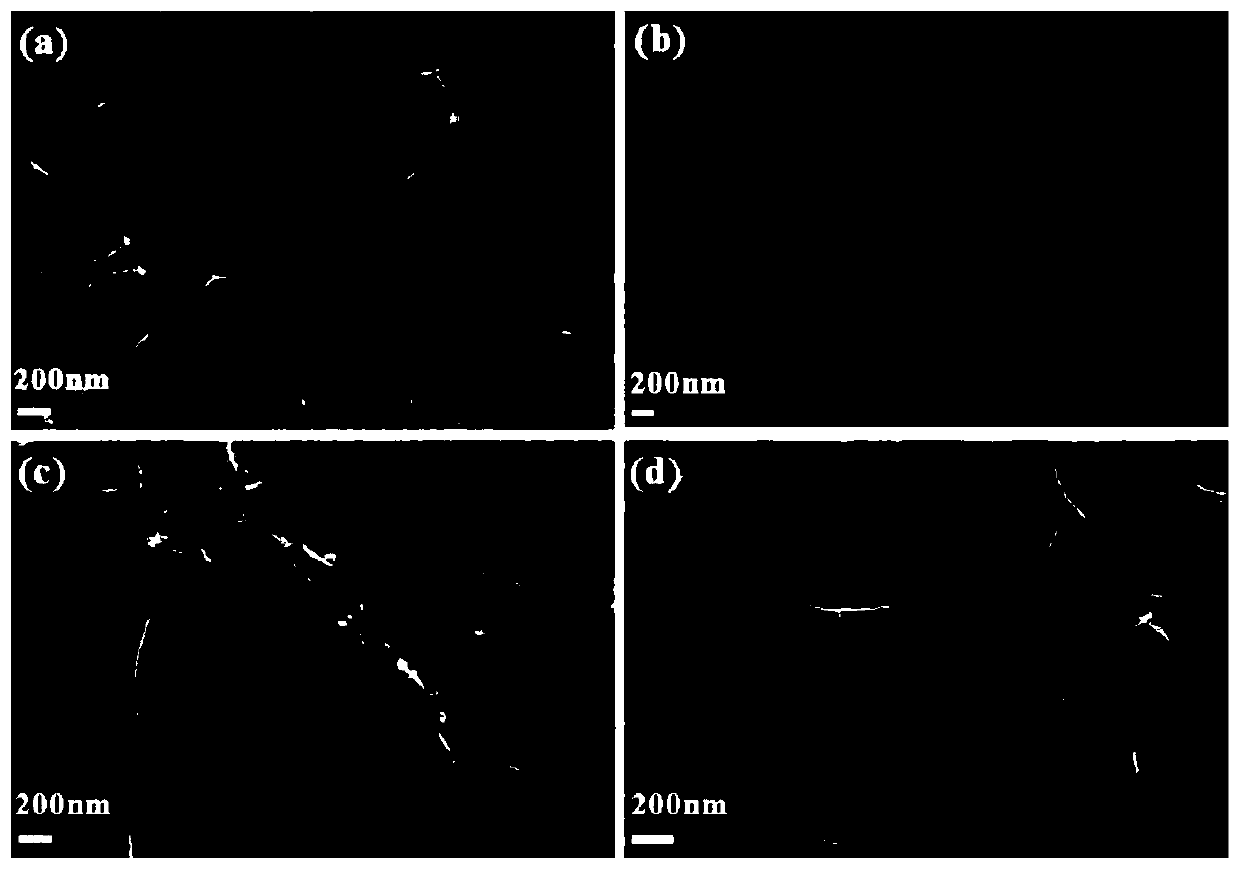

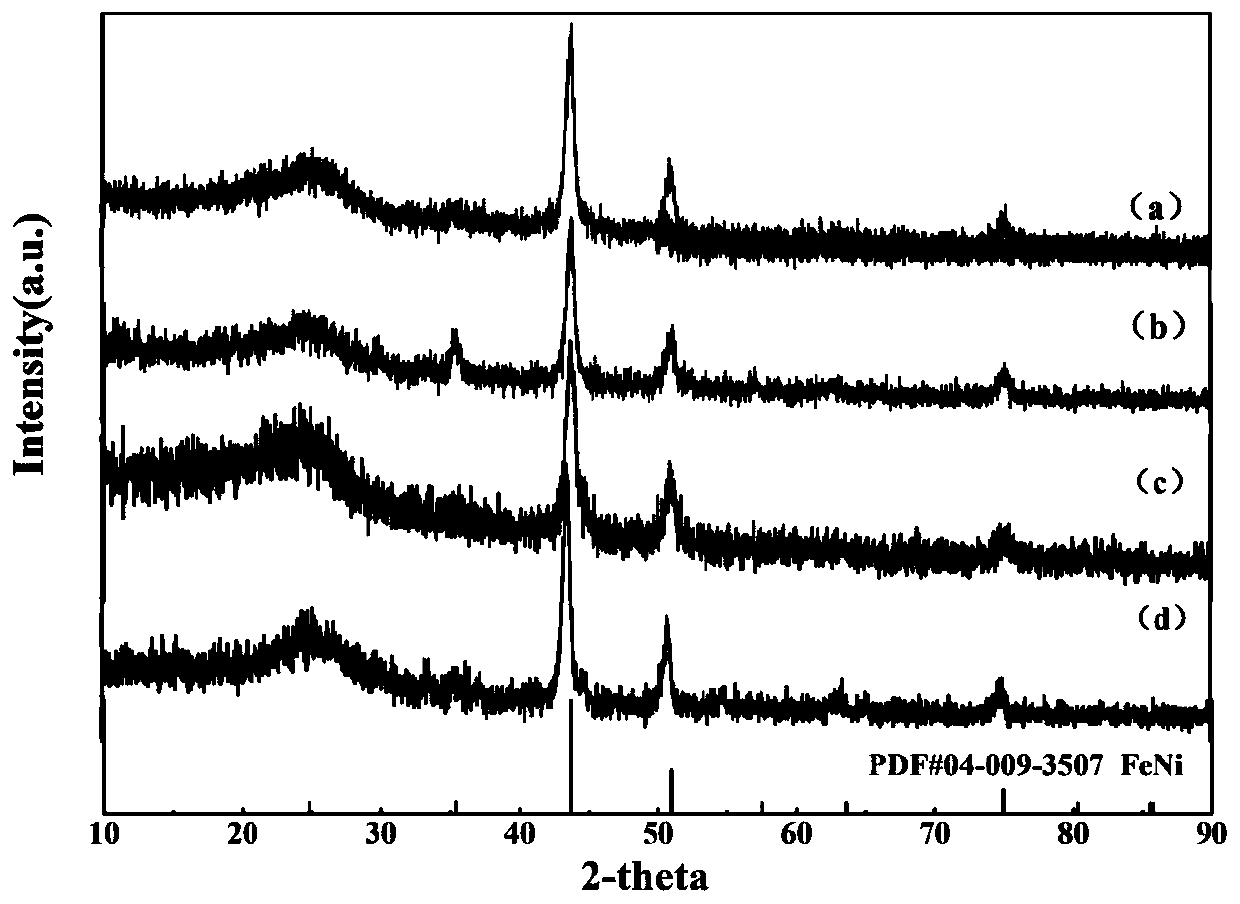

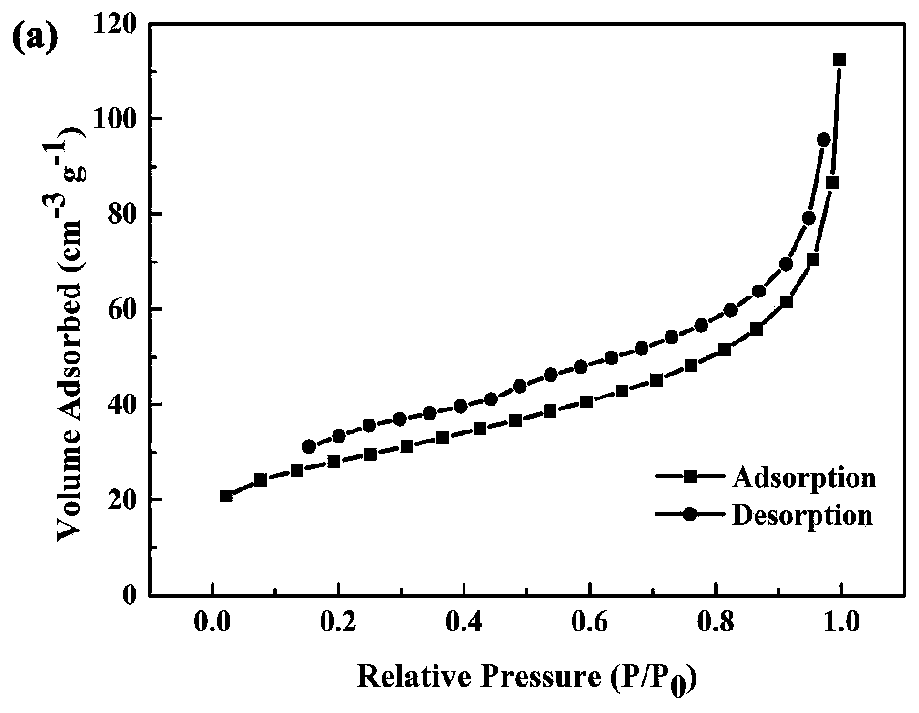

[0040] The invention provides a nanometer high-entropy alloy electrocatalyst. The nanometer high-entropy alloy electrocatalyst is composed of a three-dimensional porous carbon substrate and FeCoNiCrCu high-entropy alloy nanoparticles loaded on the three-dimensional porous carbon substrate. The diameter of the high-entropy alloy nanoparticles prepared in this example is about 50nm, which is a FeNi alloy structure (monoclinic system, space group Pm(6)), and the molar ratio of Fe, Co, Ni, Cr, and Cu is 1:1 :1:1:1.

[0041] A preparation method of nanometer high-entropy alloy electrocatalyst, it comprises the steps:

[0042] Step 1, preparation of precursor:

[0043] Take by weighing citric acid monohydrate 1.25g, urea 1.25g, template agent-sodium chloride 20.642g, after it is completely dissolved in 70mL deionized water, then weigh the doping source-ferric nitrate nonahydrate (0.1146g ), cobalt nitrate hexahydrate (0.0822g), nickel nitrate hexahydrate (0.0831g), chromium nitrat...

Embodiment 2

[0054] The invention provides a nanometer high-entropy alloy electrocatalyst. The nanometer high-entropy alloy electrocatalyst is composed of a three-dimensional porous carbon substrate and FeCoNiCrCu high-entropy alloy nanoparticles evenly loaded on the three-dimensional porous carbon substrate. The diameter of the FeCoNiCrCu high-entropy alloy nanoparticle prepared in this embodiment is about 50nm, is the FeNi alloy structure monoclinic system, the space group Pm (6), the molar ratio of Fe, Co, Ni, Cr, Cu is 1:1: 1:1:1. The three-dimensional porous carbon substrate is formed by calcining and carbonizing the carbon source in the precursor and removing the template agent-sodium chloride.

[0055] A preparation method of nanometer high-entropy alloy electrocatalyst, it comprises the steps:

[0056] Step 1, preparation of precursor:

[0057] First, weigh 1.25g of citric acid monohydrate, 1.25g of urea, and 20.642g of template agent-sodium chloride with a balance. g), cobalt n...

Embodiment 3

[0069] The invention provides a nanometer high-entropy alloy electrocatalyst. The nanometer high-entropy alloy electrocatalyst is composed of a three-dimensional porous carbon substrate and FeCoNiCrCu high-entropy alloy nanoparticles evenly loaded on the three-dimensional porous carbon substrate. The diameter of the FeCoNiCrCu high-entropy alloy nanoparticle prepared in the present embodiment is about 50nm, is FeNi alloy structure (monoclinic system, space group Pm (6)), and the molar ratio of Fe, Co, Ni, Cr, Cu is 1: 1:1:1:1.

[0070] A preparation method of nanometer high-entropy alloy electrocatalyst, it comprises the steps:

[0071]Step 1, preparation of precursor:

[0072] First take by weighing citric acid monohydrate 1.25g, urea 1.25g, template agent-sodium chloride 20.642g, after it is completely dissolved in 70mL deionized water, then weigh the doping source-ferric nitrate nonahydrate (0.1146 g), cobalt nitrate hexahydrate (0.0822 g), nickel nitrate hexahydrate (0.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com