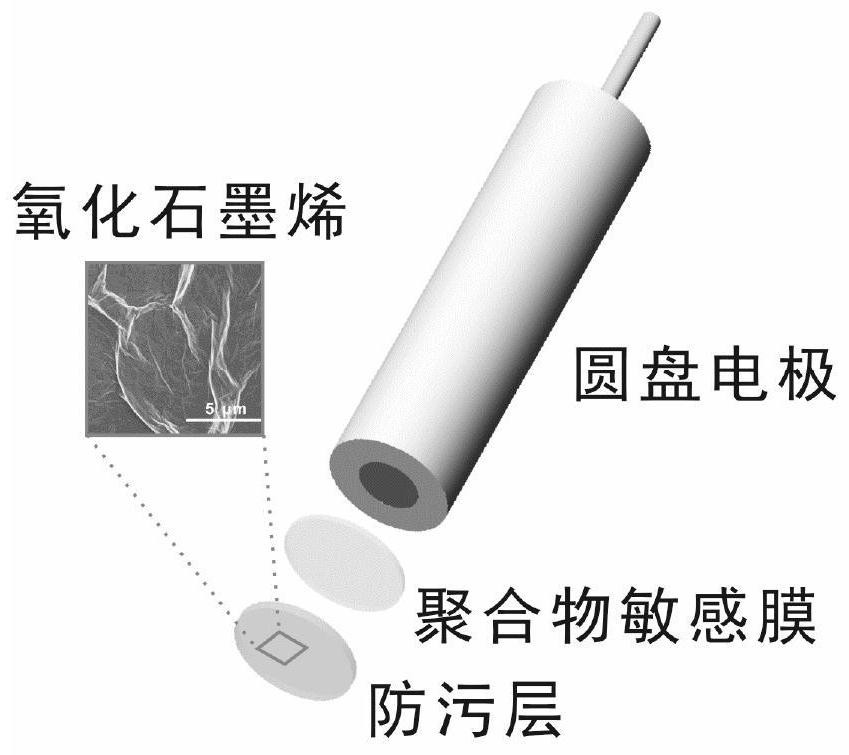

A polymer film potential type anti-biofouling sensor based on graphene oxide antifouling layer and its application

A polymer film and biofouling technology, which is applied to instruments, scientific instruments, and material analysis through electromagnetic means, can solve problems such as shortened service life of electrodes, electrode biofouling, and decreased detection performance of electrodes, so as to reduce damage , simple operation, avoid the effect of chemical modification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Taking the detection of calcium ions as an example, the specific preparation steps of the polymer membrane potential type anti-biofouling sensor based on the graphene oxide antifouling layer are as follows:

[0033] a. The configuration of the calcium ion selective membrane solution: a total of 360mg of the mixture of PVC particles, o-nitrophenyloctyl ether, calcium ionophore and tetrakis (3,5-two (trifluoromethyl) phenyl) sodium borate, wherein For 31.8wt% PVC particles, 63.7wt% o-nitrophenyloctyl ether, 2.3wt% calcium ionophore and 2.2wt% tetrakis (3,5-bis(trifluoromethyl)phenyl) sodium borate, moved to 3.6 mL tetrahydrofuran solution, stirred for 6h to disperse evenly, and the electrode sensitive membrane solution was obtained.

[0034] b. The pretreatment process of the disk electrode: taking the glassy carbon disk electrode as an example, after the polished disk electrode is ultrasonically cleaned with absolute ethanol and deionized water, the surface of the electr...

Embodiment 2

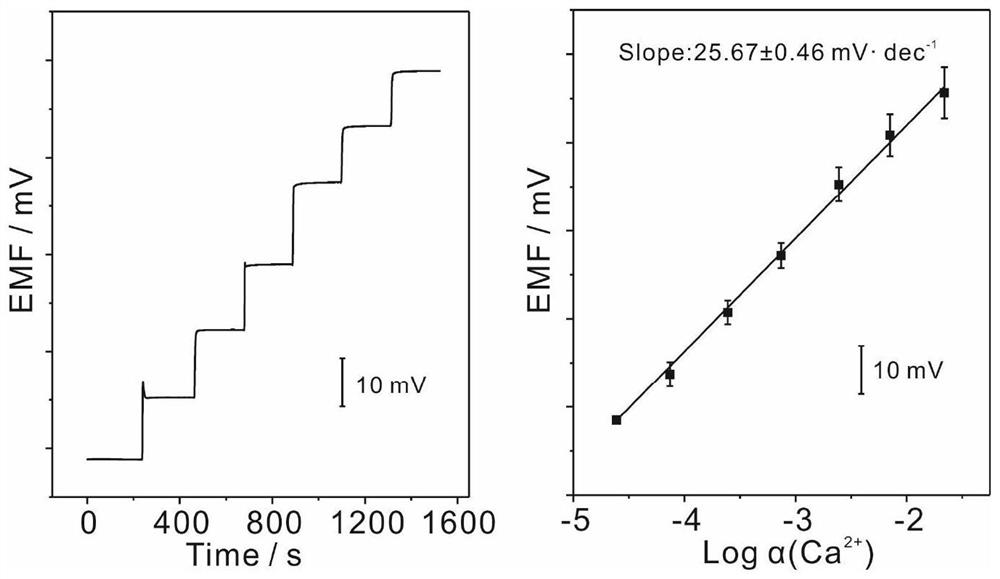

[0037] Taking the detection of calcium ions as an example, using the above embodiments to obtain the potential detection of the sensor for calcium ions:

[0038] A. the antifouling calcium ion selective electrode prepared as described in Example 1 is used as a working electrode, and the Ag / AgCl electrode is used as a reference electrode to detect the potential of different concentrations of calcium ions;

[0039] b. place the antifouling calcium ion selective electrode obtained above in 10 -3 M CaCl 2 Activation in solution overnight. Use CaCl 2 1M calcium ion stock solution (containing 0.5M NaCl) configured with NaCl, add calcium ion stock solution to the 0.5M NaCl bottom solution, so that the calcium ion in the bottom solution is 10 -4 、10 -3.5 、10 -3 、10 -2.5 、10 -2 、10 -1.5 、10 -1 M, and then use the above-mentioned detection system to detect, and record the potential values produced by different concentrations of calcium ions (see figure 2 ). After correctin...

Embodiment 3

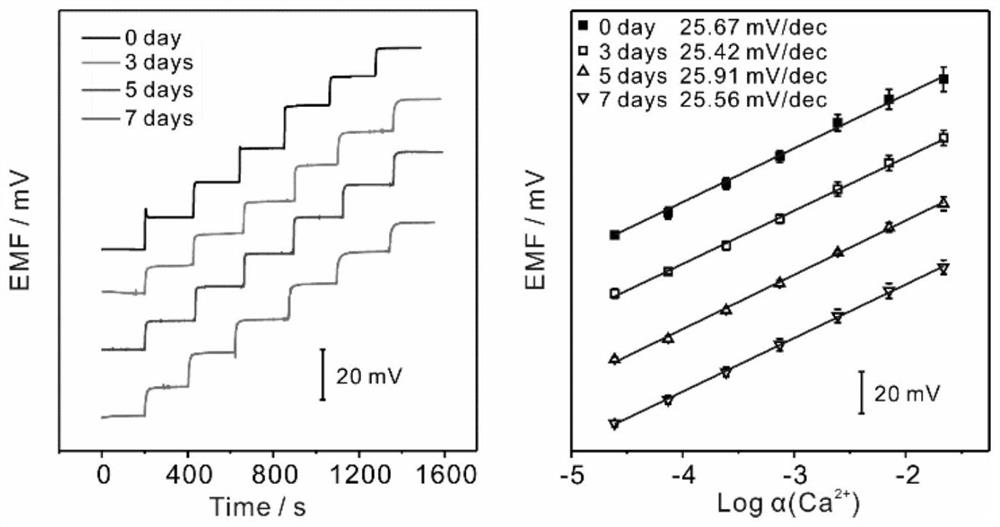

[0041] Taking the detection of calcium ions as an example, the above-mentioned embodiment is used to obtain the potential response of the sensor to calcium ions after being soaked in high-concentration bacterial solution for several days:

[0042] a. Cultivation and preparation of high-concentration bacterial solution: mix 1mL seawater and 9mL LB medium evenly and place in a shaker at 37°C for overnight culture, then take 1mL overnight culture medium containing bacteria and mix evenly with 9mL LB medium. Incubate at 37°C for 2 hours in a shaker. The bacteria were separated from the medium by centrifugation, and the bacteria were washed 3 times with sterile saline, and then the bacteria were dispersed in sterile saline to obtain a concentration of 10 8 or 10 9 CFU mL -1 The bacterial suspension was used for later use.

[0043] b. the polymer film potential type antifouling sensor obtained in embodiment 1 is placed in above-mentioned step a) bacterial suspension (10 9 CFU mL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com