Fluorescence quenching type methane sensing device based on cryptophane-A-6Me

A technology of fluorescence quenching and sensing devices, which is applied in measuring devices, fluorescence/phosphorescence, and material analysis through optical means, can solve the problems of high requirements for silicon nanowire modification technology, and achieve the advantages of fluorescence emission, simple operation, The effect of highly selective sensing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

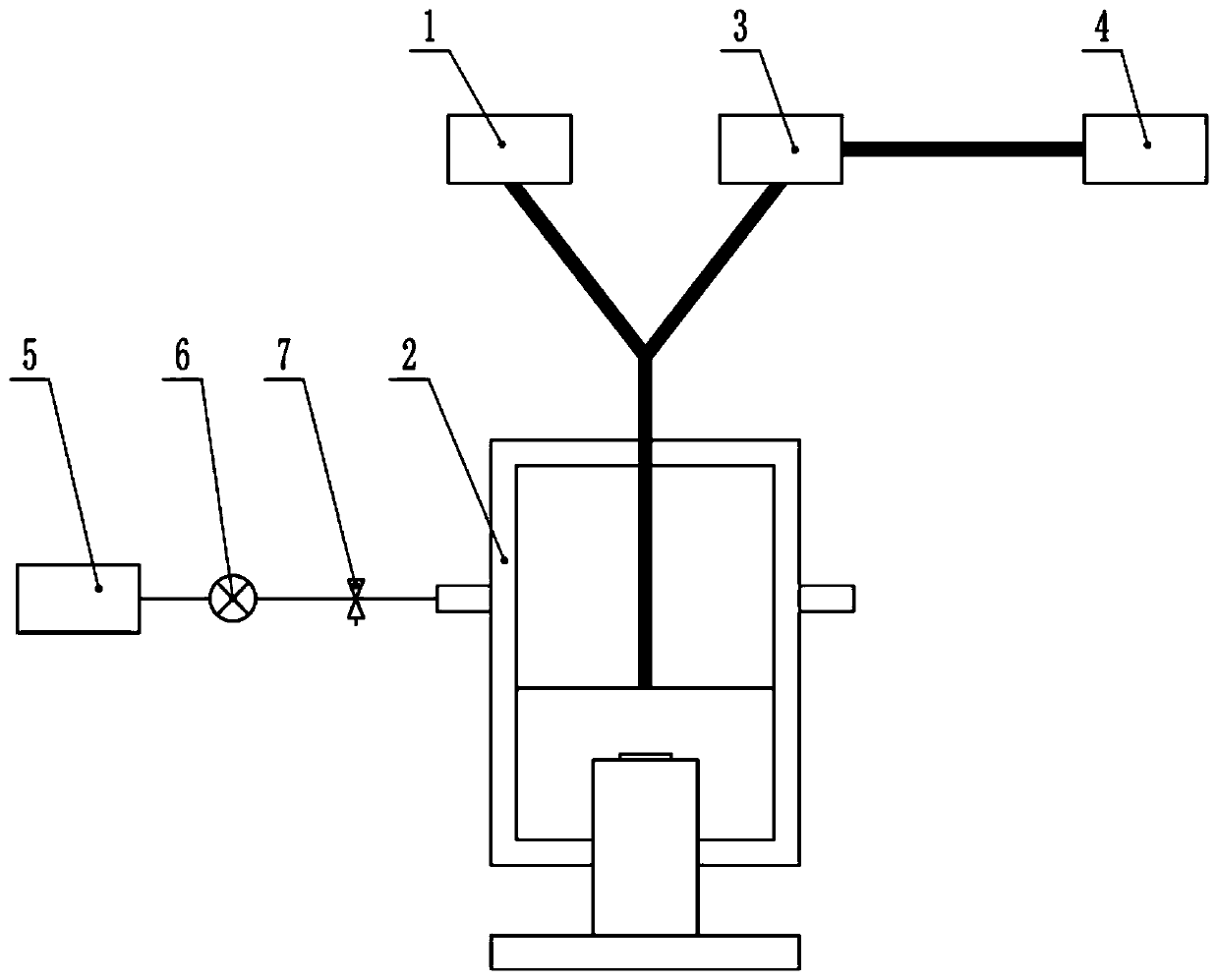

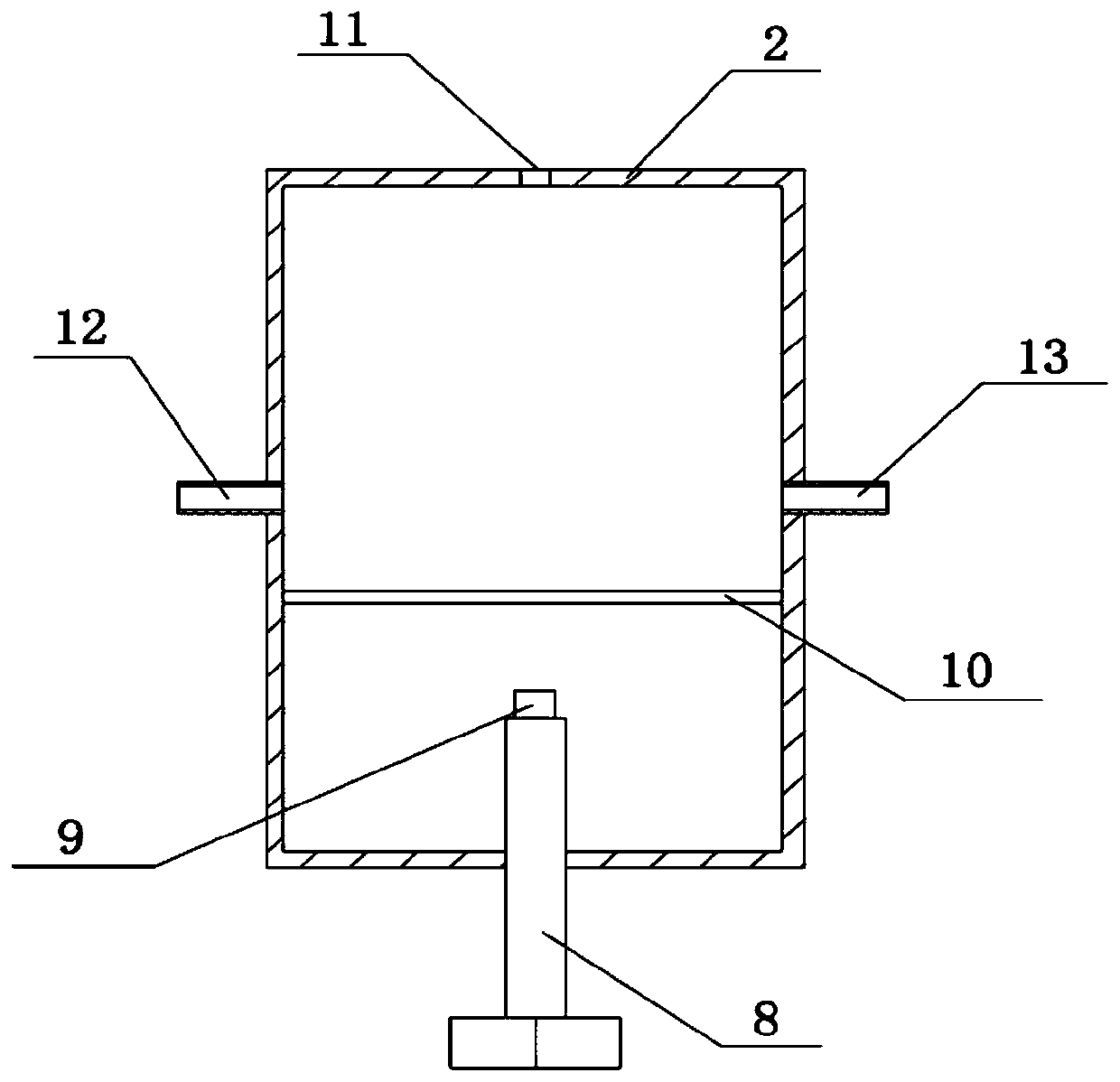

[0023] combined with figure 1 And attached figure 2 , the fluorescence quenching type methane sensing device based on Xana-A-6Me of the present invention includes a stainless steel test gas chamber 2 whose main body is a hollow cylinder, the top of the gas chamber is provided with an optical fiber inlet 11, and the bottom of the Y-shaped reflective optical fiber enters the test chamber through the inlet. Inside the gas chamber, there is a quartz glass slide 10 in the middle of the test gas chamber to fix the position of the optical fiber probe. The distance of the optical fiber probe can be adjusted through the bottom bracket 8. When the excitation light source 1 transmits light with a wavelength of 380nm through the upper left end of the Y-shaped reflective optical fiber to the sensing probe at the bottom of the optical fiber, the sensitive molecular hole in the fluorescent sensing element 8-A-6Me After being excited, blue-purple fluorescence is emitted, and the fluorescenc...

Embodiment 2

[0025] Preparation of fluorescent sensing element:

[0026]Weigh 0.01g of cryptophane-A-6Me, dissolve 0.5g of ethyl cellulose in 10mL of a mixed solvent of dichloroethane and absolute ethanol (v / v=1 / 1), stir at room temperature for 30 minutes, then sonicate for 2 hours, Transfer 50 μL to a polished and washed 1 cm×1 cm p-type silicon wafer with a pipette gun. Moist air with a relative humidity of 85% is blown to the substrate by an air pump to volatilize the solvent, and at the same time, the water vapor condenses and condenses into a large number of tiny water droplets. Finally, it is dried in a constant temperature drying oven at 60°C until the water and solvent are completely evaporated to form a fluorescent sensing element with a honeycomb porous structure. Place the fluorescent sensing element on the base of the air chamber, and screw it to 1cm away from the fiber optic probe. Taking gas standard gas with a methane concentration of 0-3.5% (v / v) as the object, the fluore...

Embodiment 3

[0032] Weigh cryptophane-A-6Me 0.01g, ethyl cellulose 0.3g is dissolved in the mixed solvent of 10mL dichloroethane and dehydrated alcohol (v / v=1 / 1) as film-forming solution, adopt and embodiment 2 The same method was used to prepare fluorescent sensing elements. Place the fluorescent sensing element on the base of the air chamber, and screw it to 1cm away from the fiber optic probe. The gas standard gas with known methane concentrations of 0, 0.6%, 1.0%, 1.5%, 2.0%, 2.5%, and 3.5% (v / v) is used for detection, and the logarithm ln[Q] of the concentrations are -0.51083, 0, 0.40541, 0.69315, 0.91629, 1.25276, the corresponding fluorescence quenching intensity ln(F 0 / F-1) are -5.19728, -4.73632, -4.3453, -4.10936, -3.97434, -3.57328, respectively. Its linear regression equation is: ln(F 0 / F-1)=0.90ln[Q]-4.73, correlation coefficient R 2 is 0.995, that is, k and b in the linear regression equation are 0.90 and -4.73 respectively.

[0033] When the methane gas to be measured...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com