Modifying method and application of carbon nanotube catalyst

A carbon nanotube and catalyst technology, which is applied in the field of carbon nanotube catalyst modification, can solve the problems of increasing surface oxygen-containing functional groups, reducing catalyst performance, and low surface group content, so as to improve propane conversion rate and excellent catalytic performance , the effect of uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

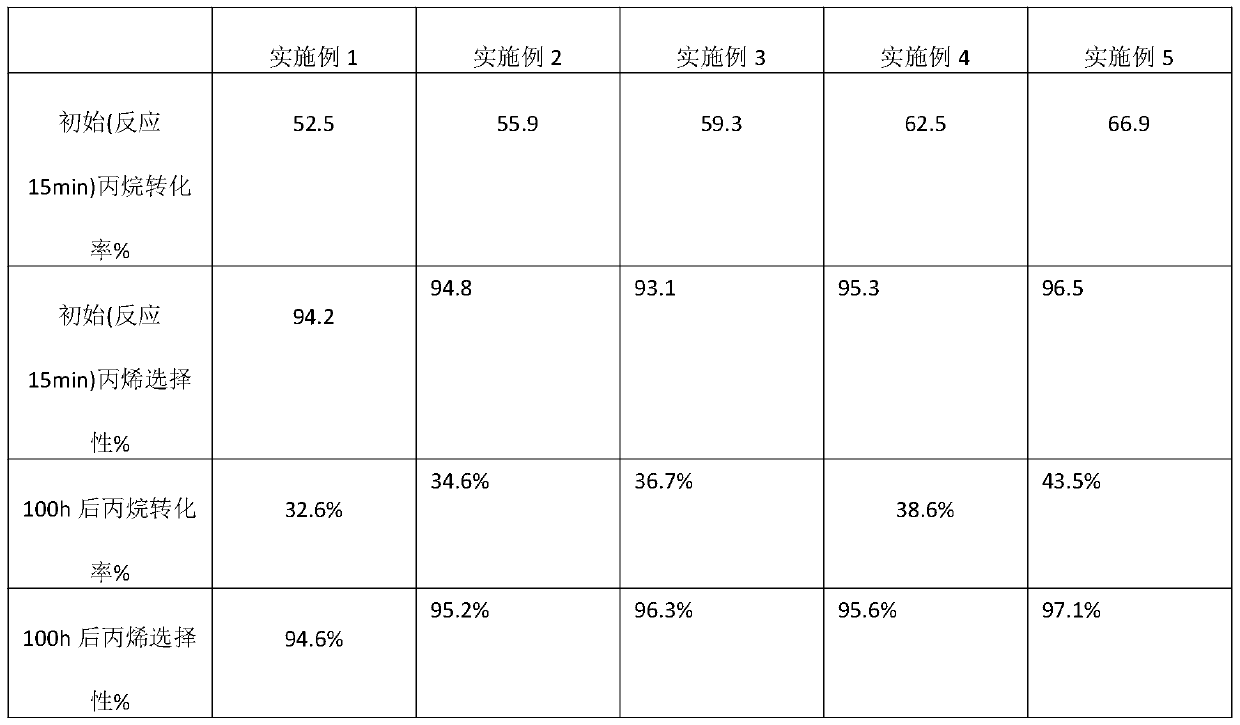

Examples

Embodiment 1

[0020] A method for modifying a carbon nanotube catalyst, comprising the steps of:

[0021] 1) Put the carbon nanotubes into a quartz boat and place them in the discharge area of the high voltage electrode and the ground electrode of the plasma processing equipment;

[0022] 2) Fill the plasma processing equipment with initiating gas oxygen, and apply a voltage of 220V between the two electrodes to adjust the pressure of the plasma device. Light discharge, treatment for 10 minutes, the modified carbon nanotube catalyst is prepared.

[0023] The application of carbon nanotube catalysts is used for the catalytic dehydrogenation of propane to produce propylene. The process conditions for catalytic dehydrogenation are: temperature 600°C, reaction pressure 0.05MPa, propane mass space velocity 3000h -1 , catalyst consumption is 0.2g.

Embodiment 2

[0025] A method for modifying a carbon nanotube catalyst, comprising the steps of:

[0026] 1) Put the carbon nanotubes into a quartz boat and place them in the discharge area of the high voltage electrode and the ground electrode of the plasma processing equipment;

[0027] 2) Fill the plasma processing equipment with initiating argon / oxygen gas, the volume ratio of argon to oxygen in the mixed gas of argon and oxygen is 95:5, and apply a voltage of 500V between the two electrodes to adjust the plasma The pressure of the bulk device, the plasma treatment pressure is 0.3 MPa, the gas flow rate is 50 sccm, and the corona discharge is carried out in an 8 kHz high-voltage power supply, and the modified carbon nanotube catalyst is obtained after treatment for 30 minutes.

[0028] The application of carbon nanotube catalysts is used for the catalytic dehydrogenation of propane to produce propylene. The process conditions for catalytic dehydrogenation are: temperature 600°C, react...

Embodiment 3

[0030] A method for modifying a carbon nanotube catalyst, comprising the steps of:

[0031] 1) Put the carbon nanotubes into a quartz boat and place them in the discharge area of the high voltage electrode and the ground electrode of the plasma processing equipment;

[0032] 2) Fill the plasma processing equipment with initiating nitrogen / oxygen gas, the volume ratio of nitrogen and oxygen in the mixed gas of nitrogen and oxygen is 75:25, and apply a voltage of 1000V between the two electrodes, and conduct the process with a 10kHz high-voltage power supply Radio frequency discharge, plasma treatment pressure of 0.2 MPa, gas flow rate of 60 sccm, treatment for 30 minutes, the modified carbon nanotube catalyst was prepared.

[0033] The application of carbon nanotube catalysts is used for the catalytic dehydrogenation of propane to produce propylene. The process conditions for catalytic dehydrogenation are: temperature 600°C, reaction pressure 0.05MPa, propane mass space veloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com