Composite material and preparation method and application thereof

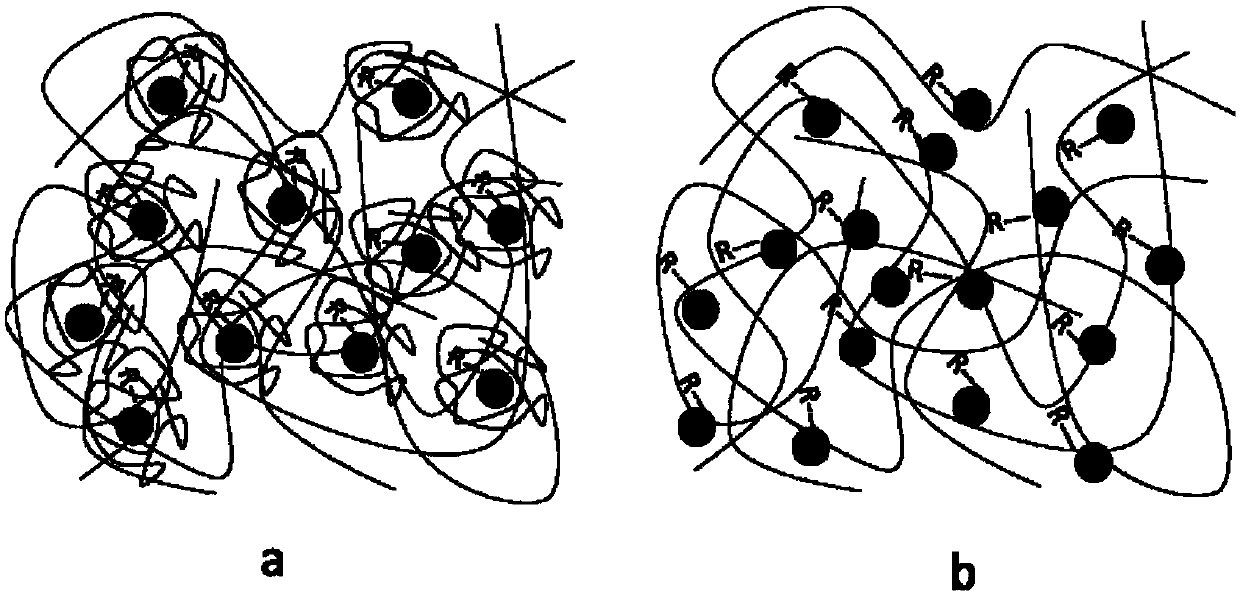

A technology for composite materials and light conversion materials, applied in the field of materials and their preparation, can solve the problems of unstable materials, large specific surface area, small particle size, etc., and achieve the effects of simple process, controllable reaction conditions and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

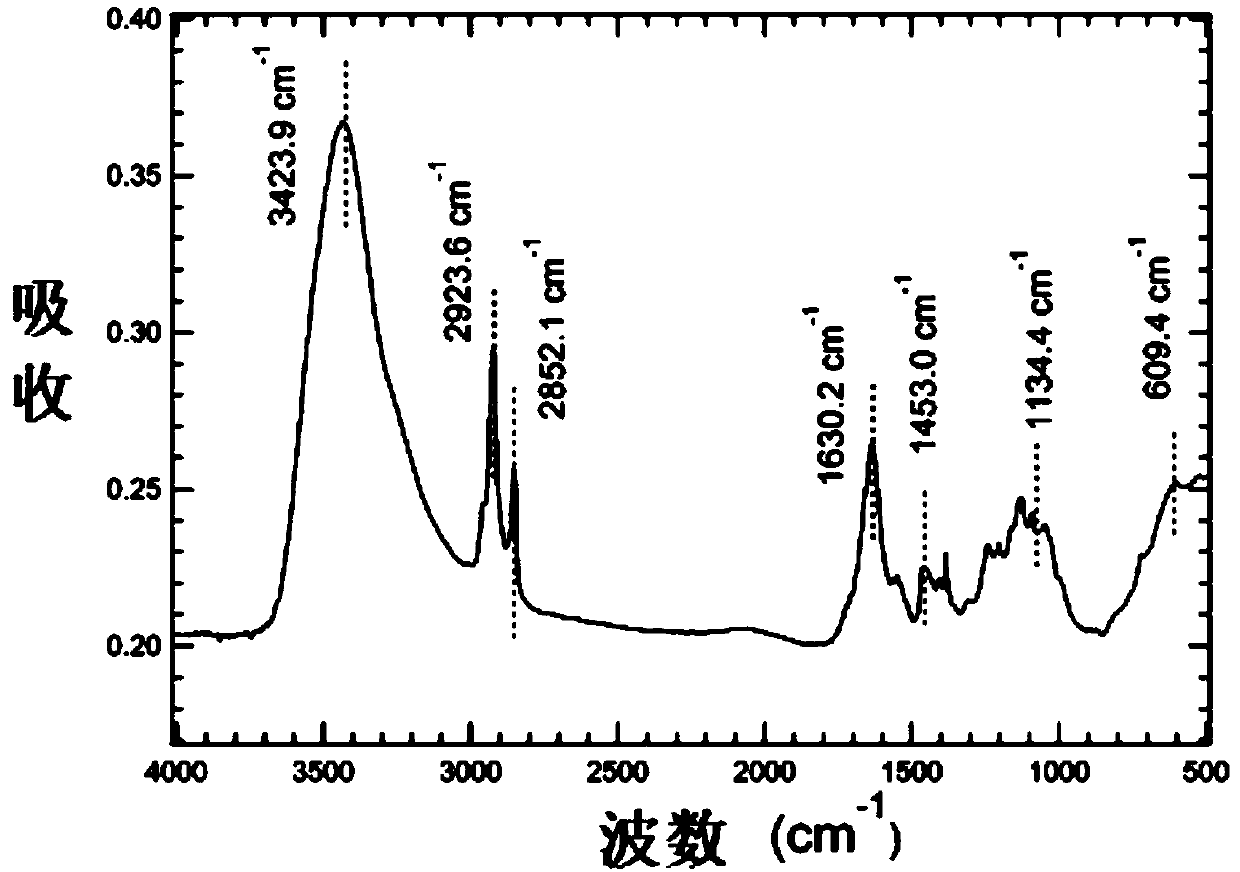

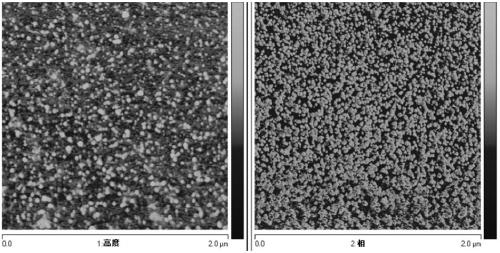

[0126] Example 1 with CH 3 NH 3 PbBr 3 / Preparation of polyvinylidene fluoride / polyacrylamide light conversion film as a composite material

[0127] The first step: in the atmospheric environment at room temperature, the perovskite quantum dot precursor PbBr 2 、CH 3 NH 3 4mmol each of Br, 100g of polymer polyvinylidene fluoride (number-average molecular weight 200000g / mol), 20g of polyacrylamide (number-average molecular weight 100000g / mol) were added to 1L dimethylformamide, mechanically stirred for 2 hours, ultrasonically dispersed for 0.5 hour, and vacuum defoaming for 1 hour to obtain the blended colloid, which can be sealed and stored in a nitrogen cabinet for 1 week. The colloidal blend is named C1, and its viscosity is measured to be 11900 mPa·s.

[0128] Step 2: Coat the blended colloid above on the PET base film through casting equipment, and adjust the scraper of the casting equipment so that the wet film thickness is 100 microns. After coating, after the wet...

Embodiment 2

[0129] Example 2 with CH 3 NH 3 PbBr 3 / Polymethyl methacrylate / bisphenol A epoxy acrylate as composite material for light conversion film preparation

[0130] The first step: weigh polymethyl methacrylate 100g (number average molecular weight 300000g / mol) under atmospheric environment, bisphenol A epoxy acrylate 40g (number average molecular weight 250000g / mol), Darocur 1173 curing agent 2g, dimethyl 1000g of methyl formamide, stirred mechanically at 65°C for 1h, then added the perovskite quantum dot precursor PbBr 2 10mmol;CH 3 NH 3 Br 3 10mmol; mechanical stirring for 0.5h, ultrasonic dispersion for 1h, standing for 2h for degassing to obtain quantum dot glue. The colloidal blend was named C2, and its viscosity was measured to be 13400 mPa·s.

[0131] Step 2: Coat the above-mentioned colloidal blend on the PET base film by casting equipment, adjust the width of the coating slit, the amount of liquid supply and the coating speed to control the wet coating thickness ...

Embodiment 3

[0132] Example 3 with CsPbBr 3 / Preparation of polyacrylonitrile as light conversion film of composite material

[0133] Step 1: Weigh CsBr, 8mmol; PbBr in atmospheric environment 2 , 8mmol; phenylethylamine bromide, 8mmol; polyacrylonitrile (number average molecular weight 150000g / mol), 100g; dimethyl sulfoxide, 1000g. The above-mentioned weighed substances were placed in a stainless steel container, mechanically stirred for 30 minutes, dispersed by a high-speed homogenizer (5000rpm / min) for 20 minutes, and then left to stand for 2 hours for degassing to obtain a quantum dot glue solution. The colloidal blend was named C3, and its viscosity was measured to be 7800 mPa·s.

[0134] Step 2: Coat the quantum dot glue solution on the PET base film through the casting equipment, adjust the width of the coating slit, the amount of liquid supply and the coating speed to control the wet coating thickness to 100 microns, the speed is 5m / min, 65 °C for 10 min to obtain a quantum dot / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com