Oil and water separation and waste water evaporation and concentration heat pump system device of oilfield oil extraction gas gathering and transportation station

A heat pump system, oil-water separation technology, applied in heat recovery systems, mining wastewater treatment, heat pumps, etc., can solve the problems of insufficient environmental protection of natural gas heating, low sewage reuse rate, etc., to eliminate waste water discharge pollution, enhance water reinjection capacity, The effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

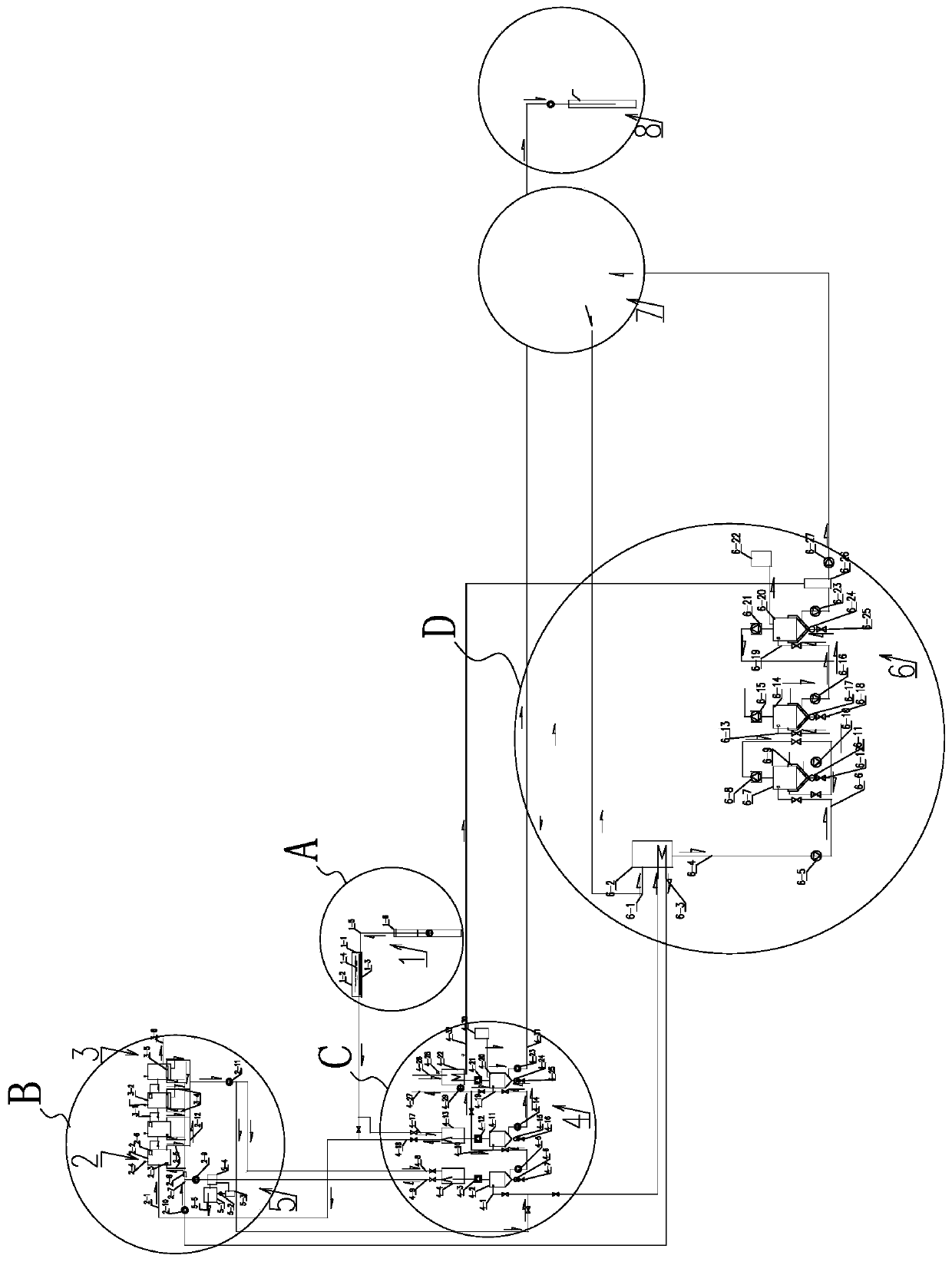

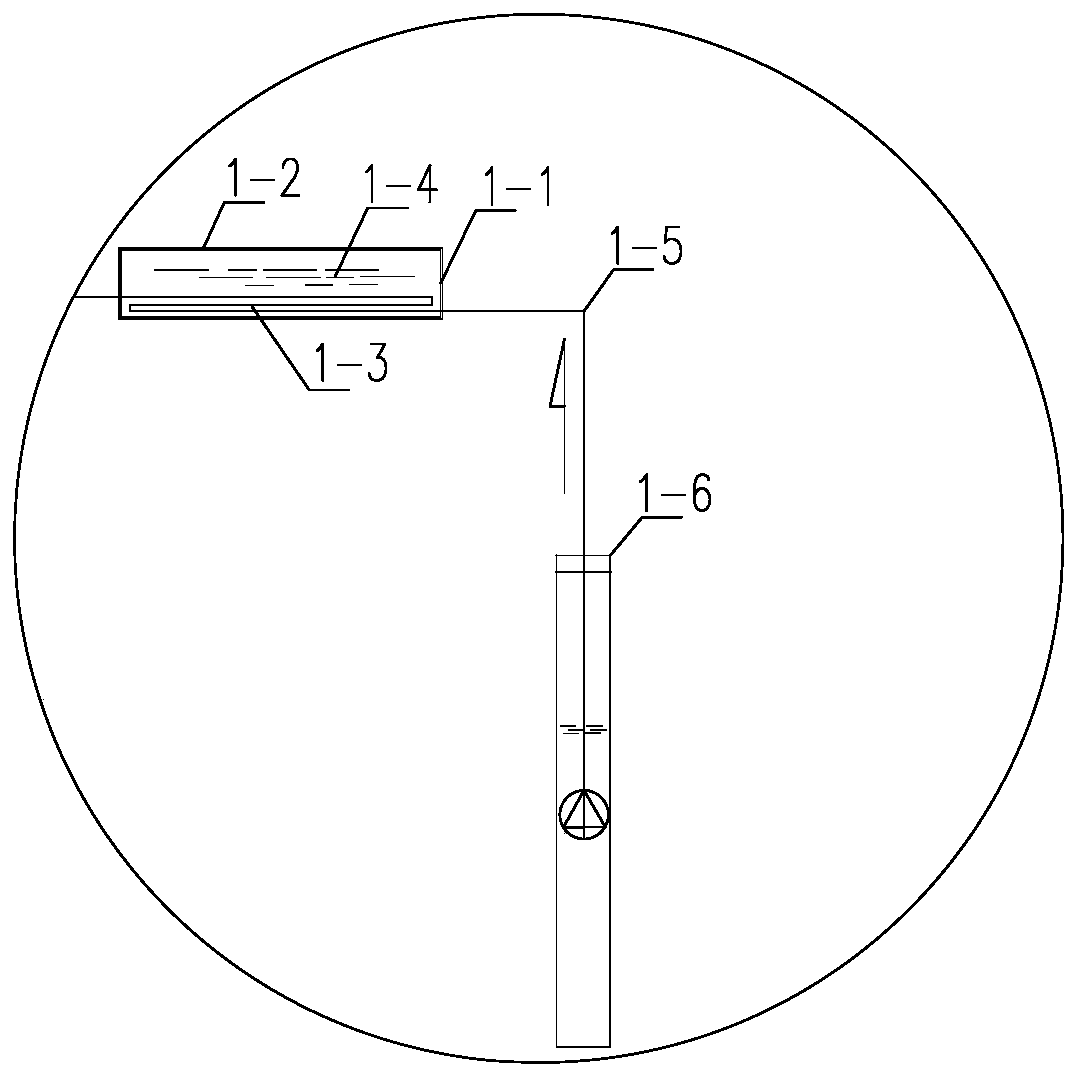

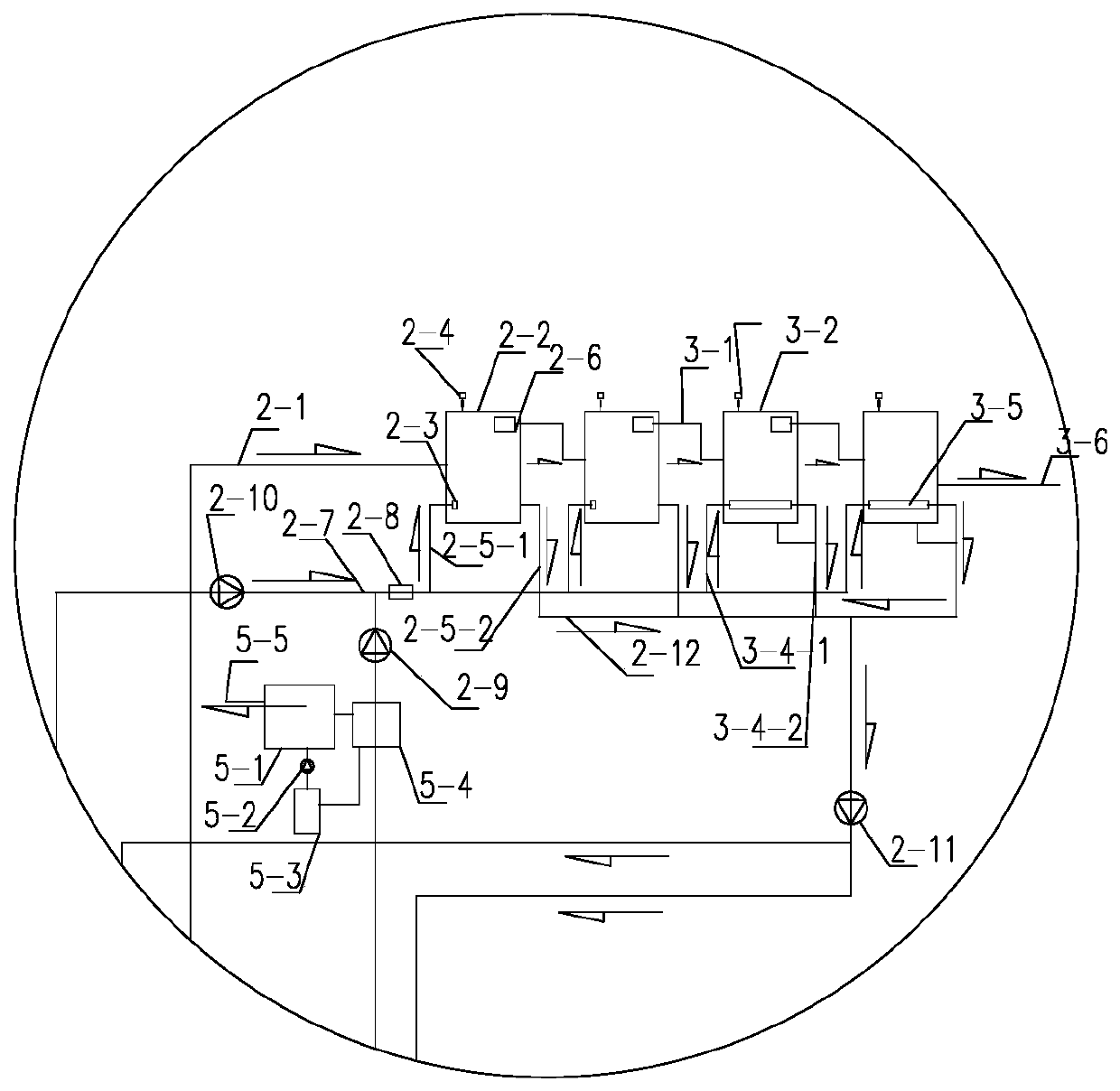

[0025] Such as figure 1 As shown, the oil-water separation and waste water evaporation concentration heat pump system device of the oil production gathering station in this oil field includes the heat exchange device 1 of the solar salt solution heat collection and storage tank at the wellhead of the oil production well, and the heat exchange device of the solar salt solution heat collection and storage tank at the wellhead of the oil production well 1 is connected with the tertiary sewage evaporative cooling and purification heat pump system 4, and the tertiary sewage evaporative cooling and purification heat pump system 4 is sequentially connected with the heating and pipeline connection system of the inbound pretreatment oil-water separation tank of the gathering station 2 and the good oil purification tank system 3. The oil purifi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap